Left and right front suspension brackets of automobile engine

A technology of automobile engine and front suspension bracket, which is applied to power units, vehicle components, jet propulsion units, etc., can solve problems such as damage, engine fall, and reduced load-bearing capacity, so as to avoid accumulating water on the surface and achieve good buffering and energy absorption. effect, effect of strong carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

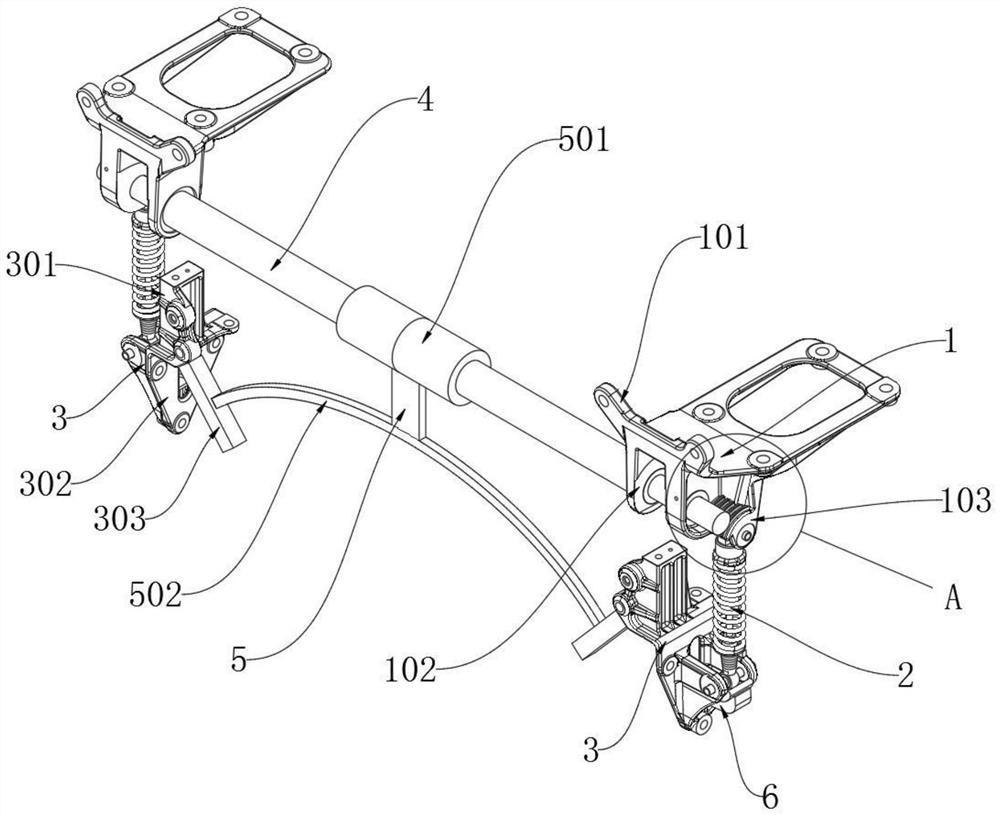

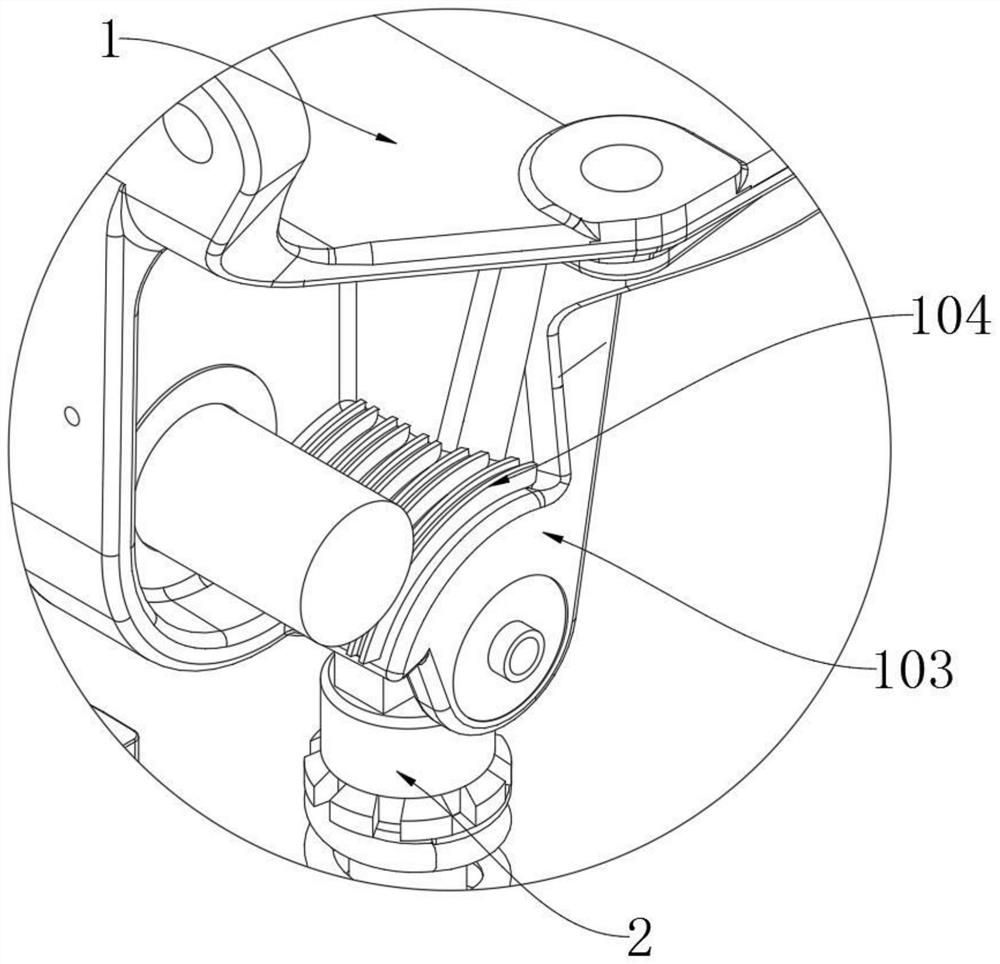

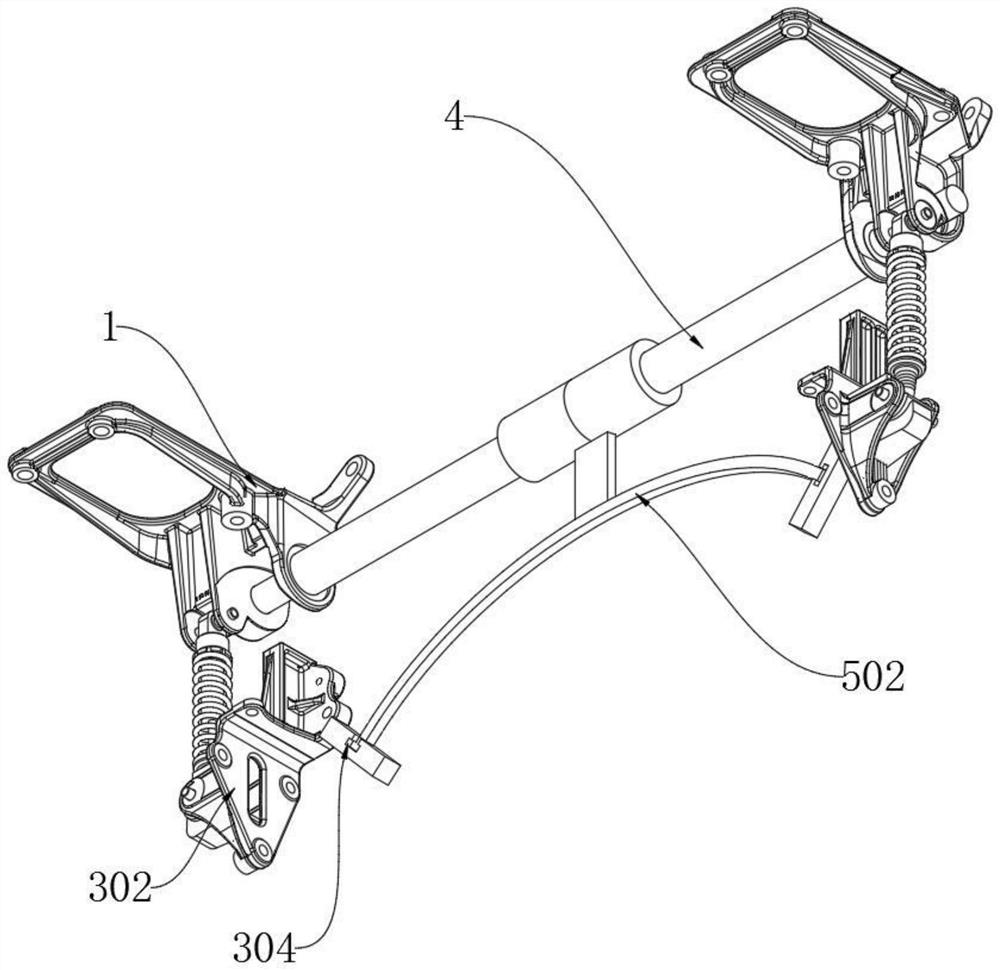

[0033] as attached figure 1 to attach Figure 8 Shown:

[0034]The present invention provides the left and right front suspension brackets of automobile engines, comprising an upper bracket 1; the lower end of the upper bracket 1 is hinged with the lower bracket 3 below through a damping spring 2; Block 303 and mortise 304, the inner side of the upper end of the lower bracket 3 is fixed vertically upward with a clamping plate 301, and the middle part of the clamping plate 301 is a closed vertical groove linear structure, which can strengthen the pulling ability, which is different from the traditional wire hole method. The structure of the lower bracket 3 is stronger than the pulling force. The outer side of the lower end of the lower bracket 3 is fixed vertically downward with the lower connecting ear 302 in the shape of an isosceles triangle. Hinged, the upper edge of the inner side wall of the lower connecting ear 302 is fixed with a rectangular parallelepiped connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com