A kind of method of synthesizing phthalimide by means of urea choline chloride eutectic

A technology of phthalimide and choline chloride, which is applied in organic chemistry and other fields, and can solve problems such as pollution and environmental discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

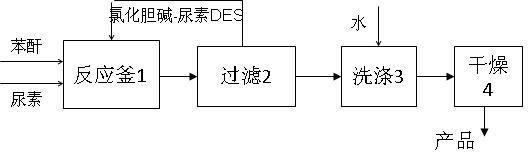

Embodiment 1

[0014] 100 kilograms of urea and choline chloride molar ratio are 2:1 urea-choline chloride deep eutectic solvent and industrial grade purity 99% phthalic anhydride 57 kilograms are added in the reactor 1, rely on the reactor jacket steam to make the reactor The inner material is heated to 130°C and reacted for 2 hours. During the reaction, urea is added twice, 16 kg each time, and phthalimide is gradually precipitated as white crystals; after that, the temperature is lowered to about 60°C, and the material is sent to the centrifuge. Filtration in the filter filter 2; the filtrate is pumped into the reaction kettle 1 for recycling; the filter cake is washed with water in the washing kettle 3, and then sent to the dryer 4 for drying to obtain 54.5 kg of phthalimide products with a purity of more than 98% .

Embodiment 2

[0016] 100 kilograms of urea and choline chloride molar ratio are 2:1 urea-choline chloride deep eutectic solvent and industrial grade purity 99% phthalic anhydride 57 kilograms are added in the reactor 1, rely on the reactor jacket steam to make the reactor Heat the material inside to 132°C and react for 2 hours. During the reaction, add urea twice, 15 kg each time, and phthalimide is gradually precipitated as white crystals; after that, the material is sent to the centrifugal filter for filtration 2 Filtration; the filtrate is pumped into the reaction kettle 1 for recycling; the filter cake is washed with water in the washing kettle 3, and then sent to the drier 4 for drying to obtain 53 kilograms of phthalimide products with a purity of more than 98%.

Embodiment 3

[0018] 100 kilograms of urea and choline chloride molar ratio are 2:1 urea-choline chloride deep eutectic solvent and industrial grade purity 99% phthalic anhydride 57 kilograms are added in the reactor 1, rely on the reactor jacket steam to make the reactor Heat the material inside to 133°C and react for 2 hours. During the reaction, add urea twice, 15 kg each time, and phthalimide gradually precipitates as white crystals; then cool down to about 60°C, and send the material into the centrifuge Filtration in the filter filter 2; the filtrate is pumped into the reaction kettle 1 for recycling; the filter cake is washed with water in the washing kettle 3, and then sent to the dryer 4 for drying to obtain 52 kg of phthalimide products with a purity of more than 98% .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com