Production method of citric acid

A production method, citric acid technology, applied in the field of microbial fermentation, can solve the problems of accelerating the metabolic cycle of Aspergillus niger, reducing the metabolic rate of bacteria, and reducing the size of Aspergillus niger balls, so as to speed up the speed of entering and exiting cells, accelerate the metabolic cycle, and compare The effect of increased surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

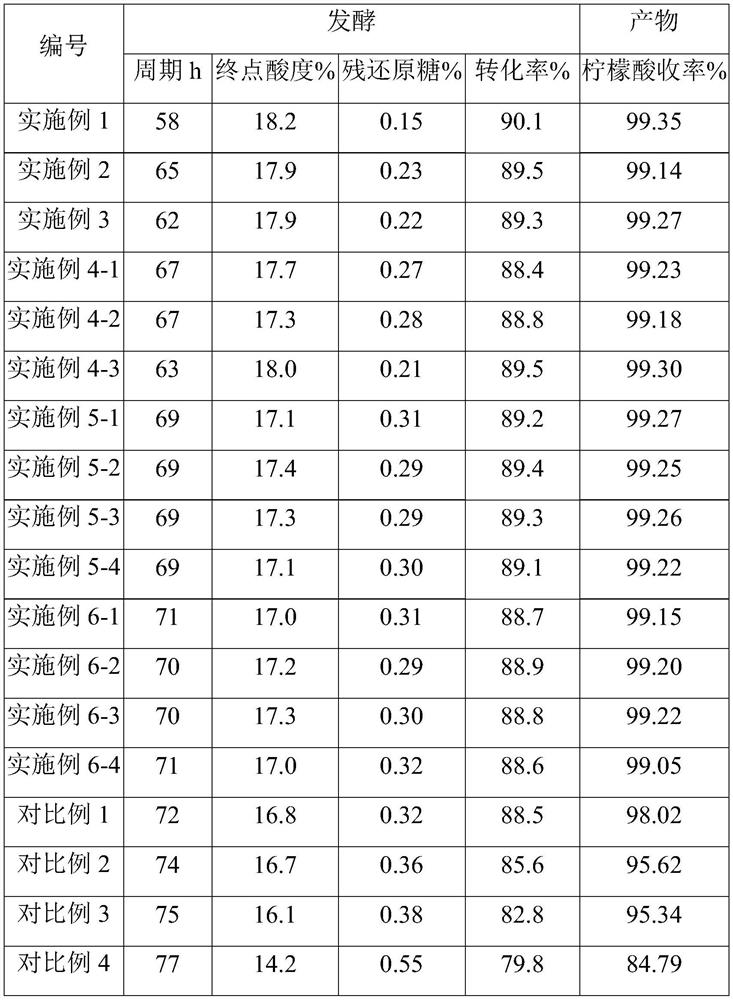

Examples

Embodiment 1

[0053] This example is used to illustrate the method for accelerating the metabolism of Aspergillus niger in the citric acid production process provided by the present invention

[0054] (1) Weigh 1kg of corn flour, wherein the particle size of corn flour is 1000-2000 μm.

[0055] (2) After mixing corn flour with 5 kg of water, sizing in a circulating water bath, the sizing temperature is 60°C, and the sizing time is 40 min.

[0056] (3) Use sodium hydroxide to adjust the pH of the product obtained by sizing to about 6, add amylase to carry out enzymatic hydrolysis and liquefaction, the addition amount of amylase is 20U / g dry base corn flour, the enzymatic hydrolysis temperature is 90 ℃, and the time is 1h .

[0057] (4) Mixing the liquefied product with a certain proportion of water to obtain a fermentation medium with a DE value of 18%. The seed liquid of Aspergillus niger was inoculated into the fermentation medium, the inoculation amount was 0.2 g, the fermentation pH wa...

Embodiment 2

[0062] This example is used to illustrate the method for accelerating the metabolism of Aspergillus niger in the citric acid production process provided by the present invention

[0063] (1) Take 1kg of dried potato, crush and sieve to obtain a particle size of 1000-2000 μm.

[0064] (2) Add 2 kg of water to the pulverized powder, and adjust the slurry in a circulating water bath for 1 hour. The temperature is 50°C, and the pH is adjusted to about 4.5.

[0065] (3) adding amylase to carry out enzymatic hydrolysis and liquefaction, the addition amount of amylase is 30U / g dry base potato, the temperature is 80°C, the pH is about 4.5, and the time is 40min.

[0066] (4) Mixing the liquefied product with a certain proportion of water to obtain a fermentation medium with a DE value of 18%. The seed liquid of Aspergillus niger was inoculated into the fermentation medium, the inoculum amount was 1 g, the fermentation pH was 4.5, and the temperature was 35° C. The fermentation was co...

Embodiment 3

[0071] This example is used to illustrate the method for accelerating the metabolism of Aspergillus niger in the citric acid production process provided by the present invention

[0072] (1) Take 1kg of corn stalks and pulverize, and the particle size of the material after pulverization is required to be 1200-2000 μm, and then subjected to steam explosion treatment.

[0073] (2) Add 10kg of water to the above-mentioned treated material, and adjust the slurry in a circulating water bath for 1 hour. The slurry temperature is 75°C and the pH is 5.

[0074] (3) Add amylase to carry out enzymatic hydrolysis and liquefaction. The addition amount of amylase is 50U / g dry basis corn stover, the temperature is 90℃, the pH is about 5, and the time is 4h.

[0075] (4) Mixing the liquefied product with a certain proportion of water to obtain a fermentation medium with a DE value of 18%. The seed liquid of Aspergillus niger was inoculated into the fermentation medium, the inoculation amoun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com