Underground space prefabricated integral structure and construction method thereof

A prefabricated assembly, underground space technology, applied in underwater structures, infrastructure engineering, artificial islands, etc., can solve the problems of unusable, secondary drilling, rebar planting, large material waste, long construction period, etc. , to increase the overall rigidity, easy operation, and reduce labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

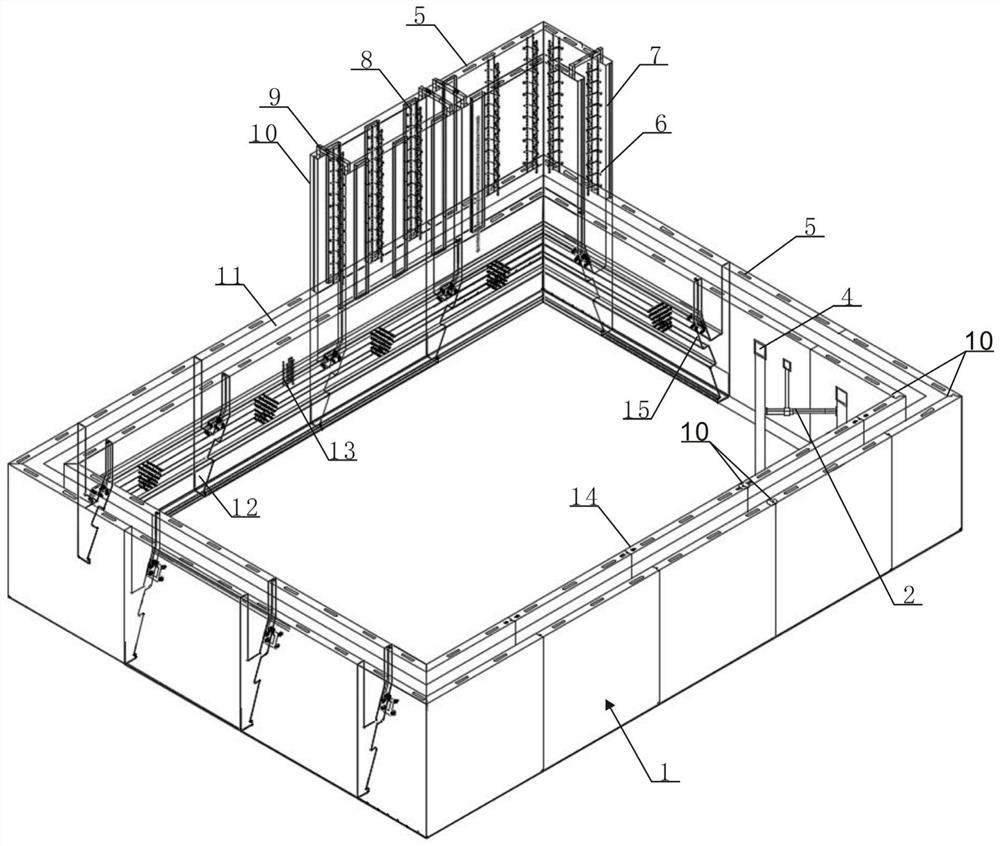

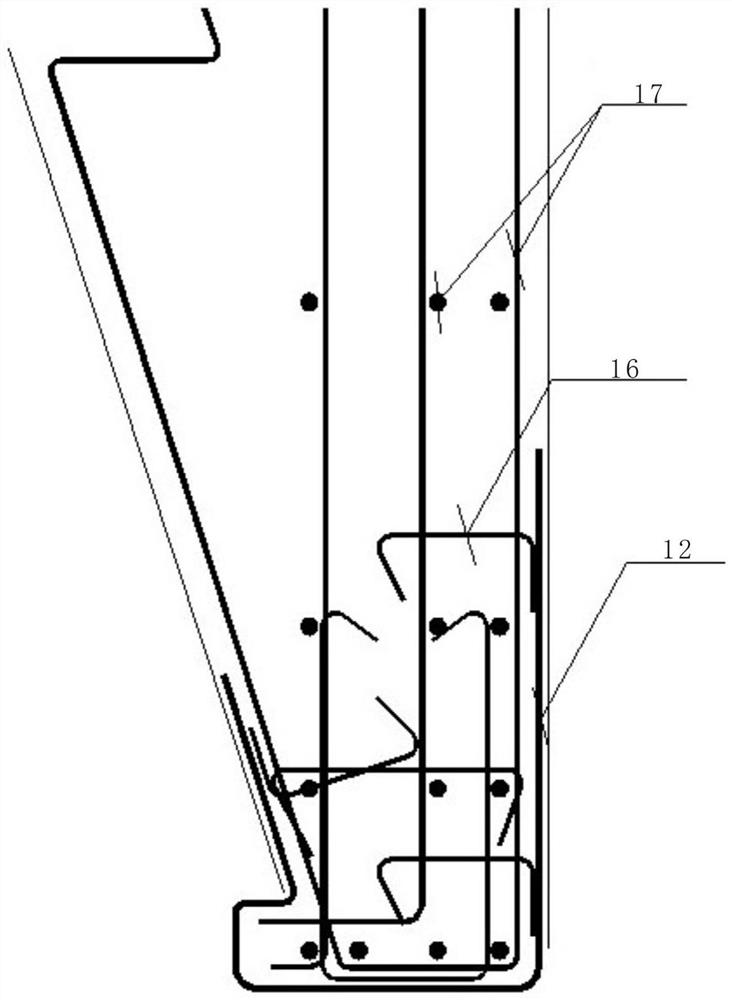

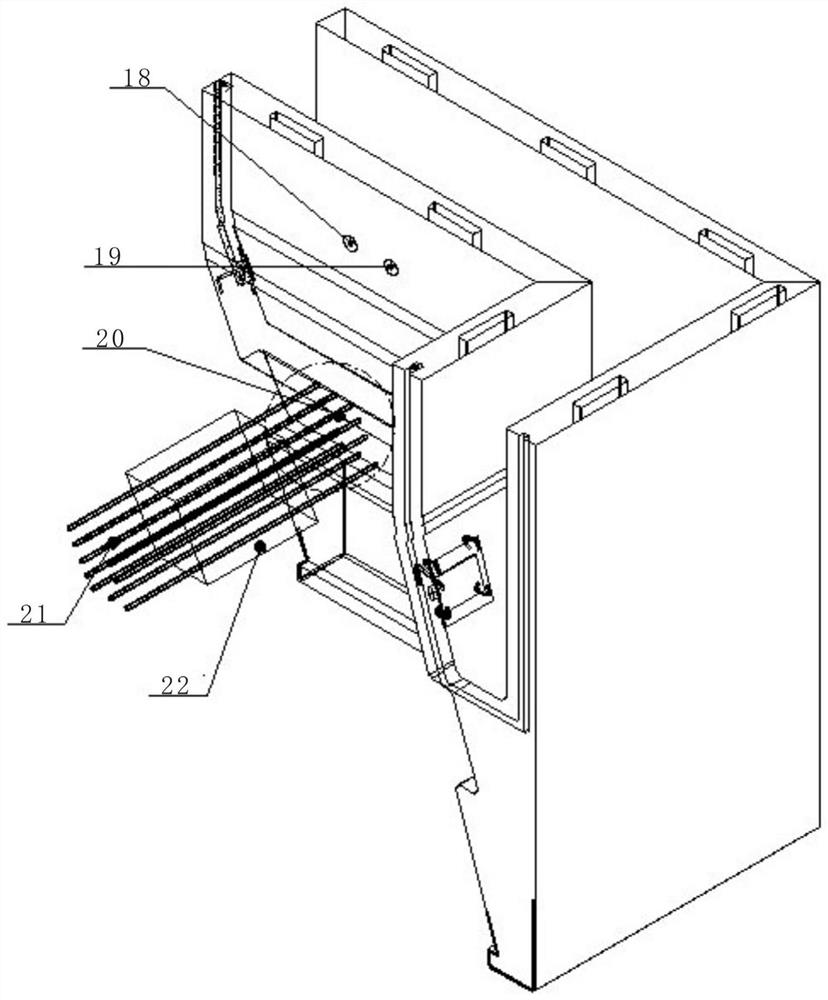

[0037] see Figure 1 to Figure 11 The described one-piece prefabricated structure for underground space includes a "U"-shaped first section caisson 37, an "H"-shaped standard section 36 arranged on the upper part of the "U"-shaped first section caisson 37, and an "U"-shaped The gusset device 2 inside the first caisson 37 of the "U" shape includes several "U"-shaped caisson components 1, and iron blades arranged inside the "U"-shaped caisson components 1. Foot 12, threaded reinforcement bar 13 and horizontal connection device 15, vertical connection reinforcement bar 11 arranged on the top of "U"-shaped caisson member 1, and the top surface of "U"-shaped caisson member 1 is provided with connection reinforcement grouting Holes 14; the "H" type standard section 36 includes the "H" type laminated wall panel 6 fixed on the top of the "U" type ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com