Device for arranging frequency modulation mass damper away from vibration point

A technology of frequency modulation mass damping and steel wire rope, which is applied to building components, anti-vibration, building types, etc., can solve the problems of increasing the difficulty of early installation of frequency modulation mass dampers and maintenance costs in the later period, so as to facilitate installation and later maintenance, and improve energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

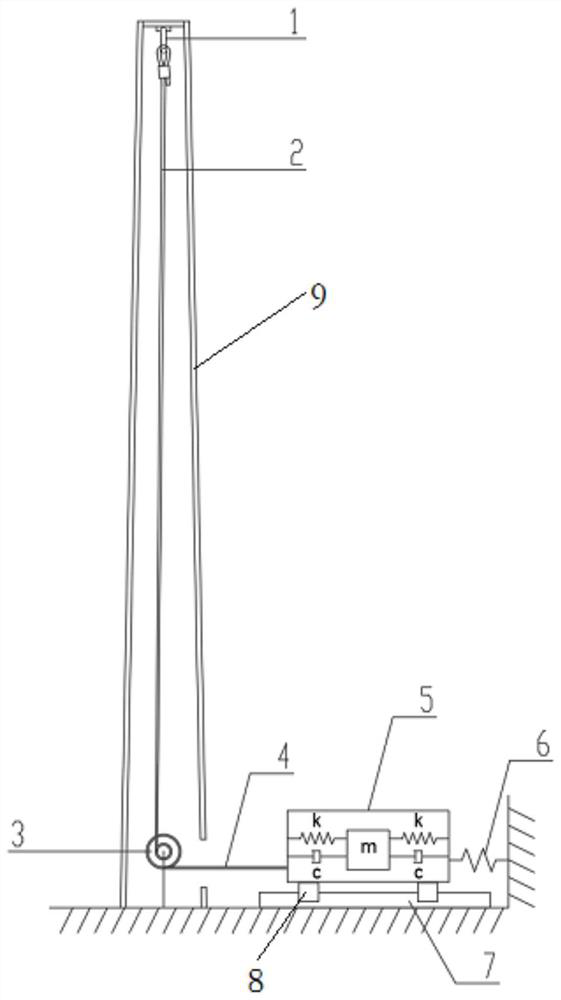

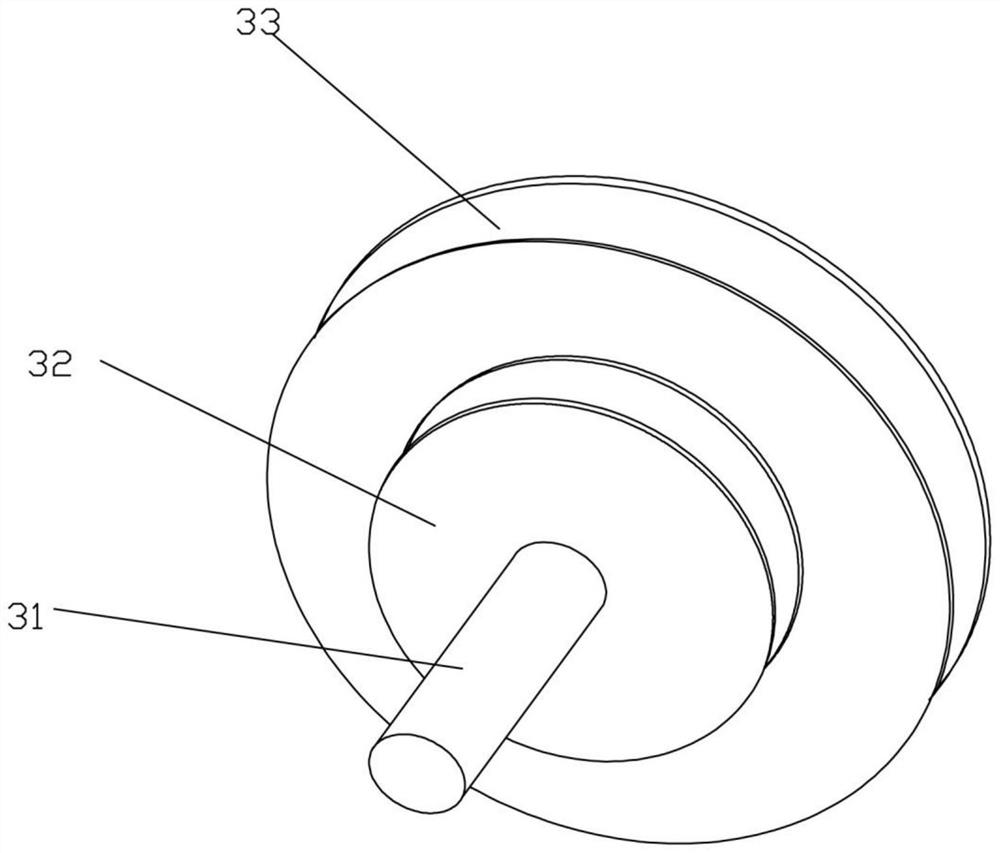

[0014] Example: A device for arranging a frequency-modulated mass damper away from the point of vibration, such as Figure 1-Figure 2 As shown, it includes lifting lugs, a first steel wire rope, a concentric pulley block, a second steel wire rope, a horizontal frequency-modulated mass damper, a tension spring, and a linear guide rail. The concentric pulley block is suspended and fixed on the ground, and the concentric pulley block includes a central shaft and Rotate the first pulley and the second pulley arranged on the central shaft, the first pulley and the second pulley are concentric and fixed together and cannot rotate with each other, that is, the first pulley and the second pulley rotate at the same time and have the same angular velocity , the lifting lug is connected to the structural vibration point, one end of the first steel wire rope is connected to the lifting lug, the other end is wound on the first pulley of the concentric pulley block, one end of the second ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com