A roadway excavation method for electrode directional impact operation

A technology of electrodes and tunnels, which is applied in tunnels, earthwork drilling, mining equipment, etc., can solve the problems of slow tunneling progress in underground tunnels, unfavorable mine environmental protection and high-efficiency production, and affects the normal progress of tunneling projects, so as to reduce tunneling costs and ensure Safe and efficient production work, low-cost implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing.

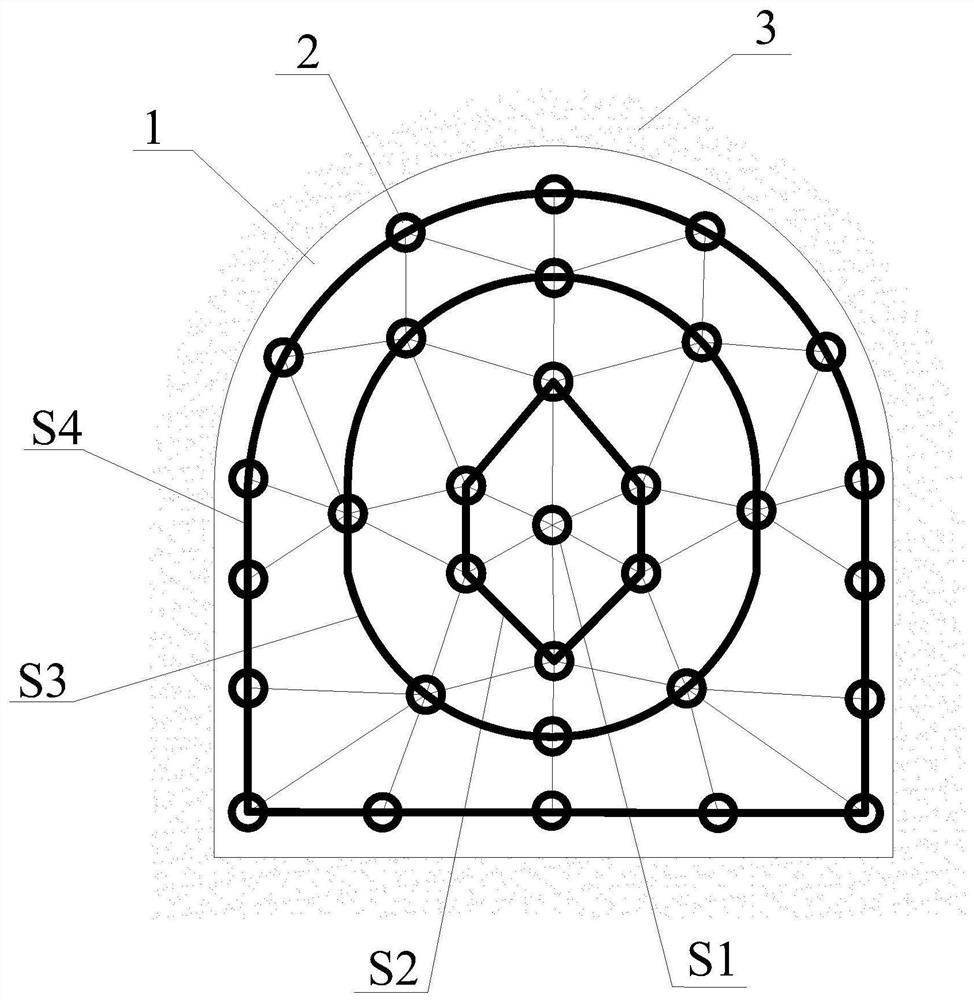

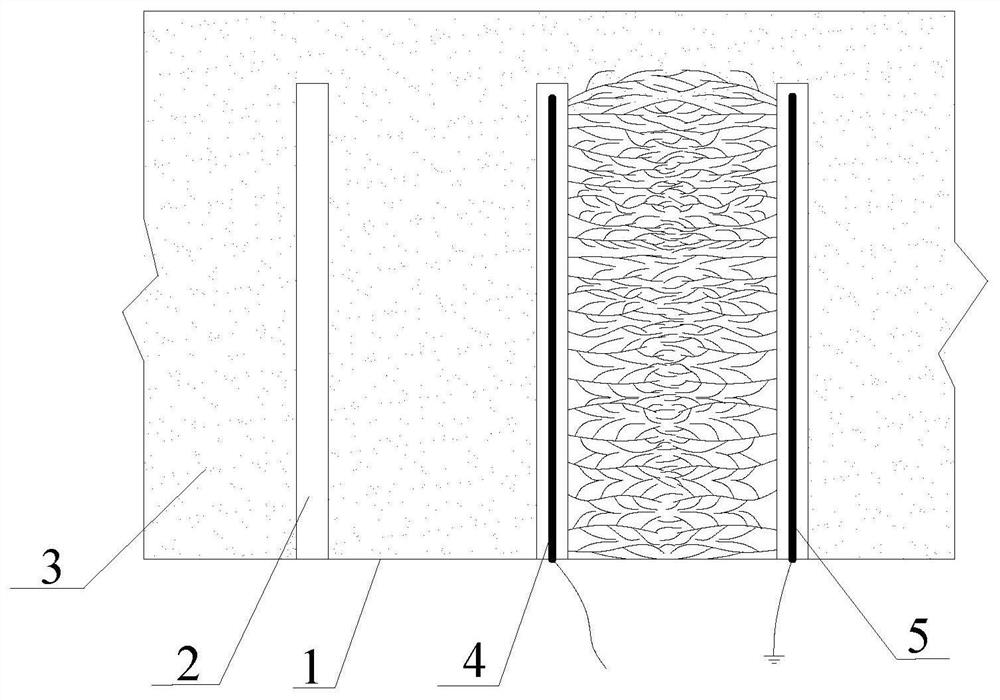

[0034] like figure 1 and figure 2 As shown, a roadway excavation method for electrode directional impact operation, specifically includes the following steps;

[0035] a. Several boreholes 2 are set on the roadway excavation surface 1, several boreholes 2 are spread over the roadway excavation surface 1, and the boreholes 2 are all perpendicular to the roadway excavation surface 1 and driven into the inside of the rock formation 3, and extend to the design Certain depth, several boreholes 2 are arranged as follows;

[0036] S11: laying out the first group of drilling holes S1;

[0037] Open a borehole 2 at the center of the roadway driving face 1;

[0038] S12: laying out the second group of drilling holes S2;

[0039] Arranging six boreholes 2 in a hexagonal arrangement around the outside of the borehole 2 at the central position;

[0040] S13: laying out the third ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com