Operation method of double back-pressure double-rotor interchange type driving feed pump turbine

A technology of feedwater pump steam turbine and operation method, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., and can solve the problems that the efficiency of the drive feedwater pump steam turbine cannot be optimal, and the heat supply capacity of the main engine that affects the performance of the drive feedwater pump steam turbine, etc. Achieve the effect of maintaining high-efficiency operation and meeting the needs of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0012] Example.

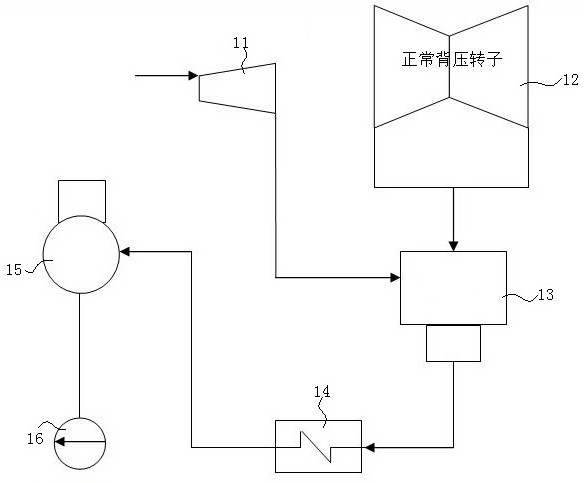

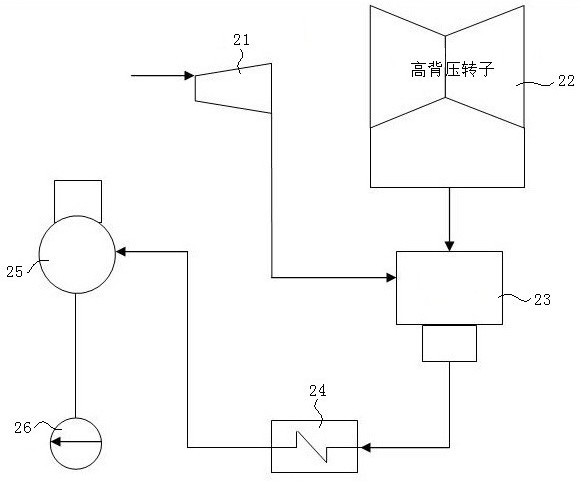

[0013] see Figure 1 to Figure 2 , this embodiment discloses a double back pressure double rotor interchangeable drive feed water pump steam turbine operation method, the operation method is implemented by a double back pressure double rotor interchangeable drive feed water pump steam turbine operating system, double back pressure double rotor mutual The replacement drive feedwater pump steam turbine operating system includes the original feedwater pump steam turbine operating system and the high back pressure feedwater pump steam turbine operating system that work together.

[0014] In this embodiment, the original feedwater pump steam turbine operating system includes the original feedwater pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com