Analysis equipment and analysis system of spent fuel reprocessing plant

A technology for spent fuel and equipment, applied in the field of analysis equipment and analysis systems of spent fuel reprocessing plants, can solve the problems of radioactive atmosphere leakage, poor sealing performance of fume hoods, poor reliability, etc., to simplify operation, facilitate use and maintenance, The effect of meeting the needs of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment provides an analysis equipment for a spent fuel reprocessing plant, including:

[0028] The sample sending and receiving shielded box room is used to receive and distribute the radioactive samples to be analyzed in the spent fuel reprocessing plant. The sample sending and receiving shielded box room has a radioactive shielding function;

[0029] The pretreatment shielding chamber is connected to the sample sending and receiving shielding chamber through the first passage, and the side walls of the pretreatment shielding chamber connected to the first passage are respectively connected with the side walls of the sample sending and receiving shielding chamber. For the first cover door to be opened and closed, the pretreatment shielding chamber is used for pretreatment of the radioactive samples to be analyzed therein, and the pretreatment shielding chamber has a radioactive shielding function;

[0030] The analysis shielding chamber is connected to the pre...

Embodiment 2

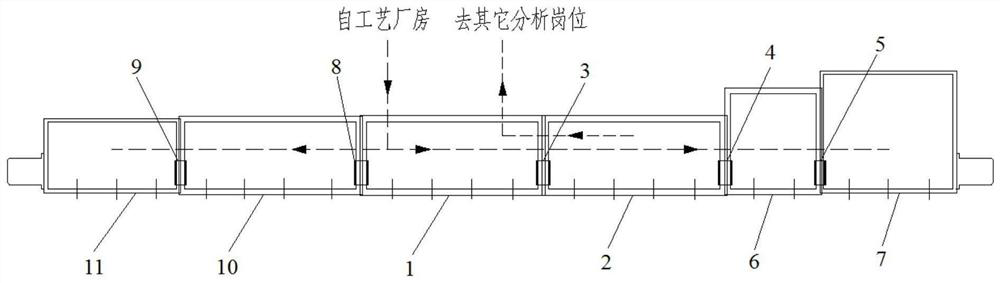

[0033] Such as figure 1 As shown, this embodiment provides an analysis equipment for a spent fuel reprocessing plant, including:

[0034] The sample sending and receiving shielded box room is used to receive and distribute the radioactive samples to be analyzed in the spent fuel reprocessing plant. The sample sending and receiving shielded box room has a radioactive shielding function;

[0035] The pretreatment shielding chamber is connected to the sample transmitting and receiving shielding chamber through the first passage 3, and the side walls of the pretreatment shielding chambers respectively connected to the first passage 3 are sealed and connected to the side walls of the sample transmitting and receiving shielding chamber. The first passage 3 A first cover door for opening and closing is arranged inside, and the pretreatment shielding chamber is used for preprocessing the radioactive samples to be analyzed in it, and the pretreatment shielding chamber has a radioactive...

Embodiment 3

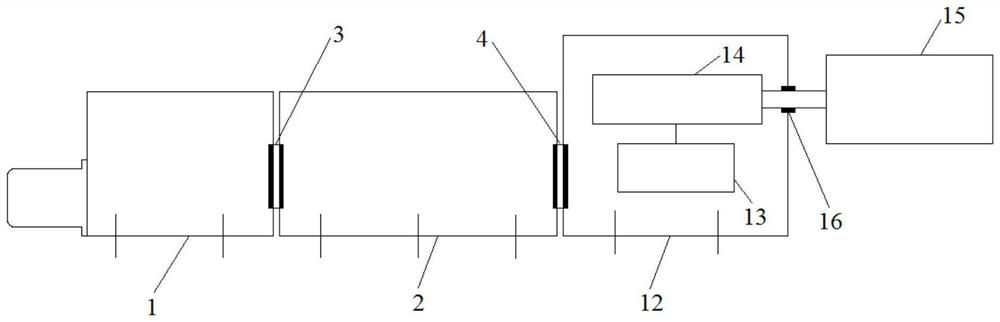

[0062] Such as figure 2 As shown, this embodiment provides an analysis equipment for a spent fuel reprocessing plant, which differs from the analysis equipment for a spent fuel reprocessing plant in Example 2 as follows:

[0063] The analysis shielding chamber in the present embodiment comprises: the first analysis shielding chamber, the first analysis shielding chamber is connected with the pretreatment shielding chamber through the second passage 4, and the pretreatment shielding chamber connected by the second passage 4 is respectively The side wall is in sealing connection with the side wall of the first analysis shielding chamber, and the first analysis shielding chamber is used to contain the parts of the first analysis instrument that contact the radioactive sample and / or the parts that rarely contact the radioactive sample. The part of the first analysis instrument that does not touch the radioactive sample is located outside the first analysis shielding box

[0064]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com