Exhaust valve plate and compressor

An exhaust valve plate and exhaust port technology, which is applied in the field of compressors, can solve the problems of exhaust valve plate rupture and reduce compressor performance, etc., and achieve the effects of easy processing, improved reliability, and reduced probability of fatigue rupture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

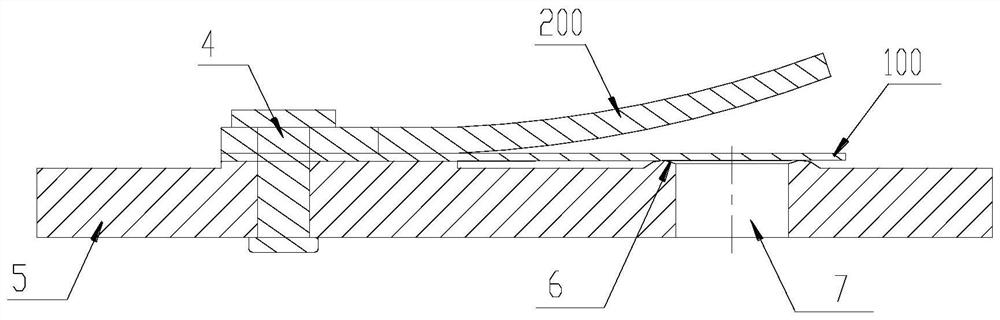

[0033] Such as Figure 2-7 As shown, the present invention provides an exhaust valve plate, wherein:

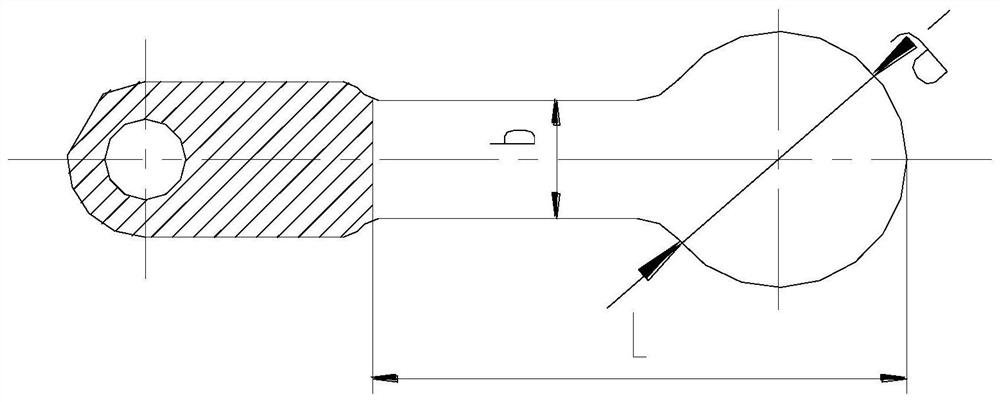

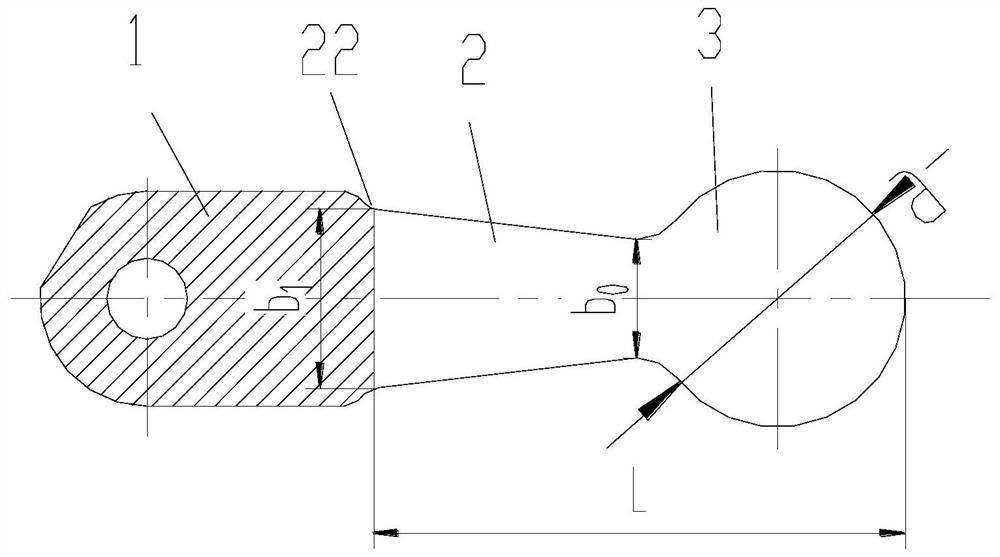

[0034] It includes a root section 1, a waist section 2 and a head section 3, the head section 3 is opposite to the exhaust port, the root section 1, the waist section 2 and the head section 3 are connected as one, and the The waist section 2 is located between the root section 1 and the head section 3, the width of the joint between the waist section 2 and the root section 1 is b1, and the waist section 2 and the head section The width at the junction of 3 is b0, and the width of the waist segment 2 is set as b1>b0.

[0035]In the present invention, the width of the waist section in the exhaust valve sheet is set to be larger than the width of the junction with the root section than the width of the junction with the head section, so that the waist section can be formed into a variable-width design structure, so that the waist section The stiffness is smaller at the junctio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com