Gear shifting mechanism with self-positioning and gear shifting return functions

A shift mechanism, self-positioning technology, applied in the direction of components with teeth, mechanical equipment, belts/chains/gears, etc., can solve the ability to keep the shift lever in the middle position all the time, and affect the service life of the shift mechanism. , The shift lever is prone to problems such as shaking gaps, which can improve the handling experience, the structural design is reliable and reasonable, and the effect of avoiding shifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

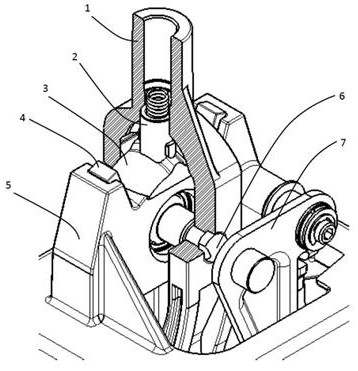

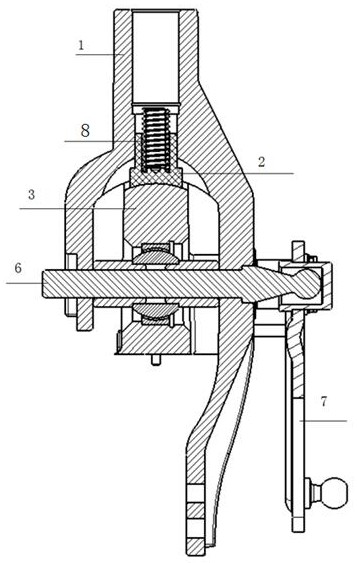

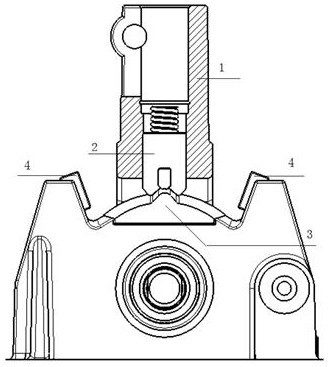

[0041]Combine belowFigure 1 to Figure 14, To further explain the present invention:

[0042]A shifting mechanism with self-positioning and shifting return, including a shift lever 1 and a mechanism housing 5. The upper end of the shift lever 1 is connected with a control lever, and the lower end of the shift lever 1 is connected with the shift flexible shaft of the automobile. The inner cavity of the shift lever 1 provides the movement space of the slider 2; the slider 2 is located in the inner cavity of the shift lever 1 and can move on the slider seat 3, and the central shaft 6 realizes the shift lever 1, the gear selection rocker 7 The connection with the mechanism housing 5 is characterized in that the slider 2 is provided with a plurality of friction pairs to cooperate with the slider seat 3 to realize the switching of different gear positions, and to avoid the reduction of service life caused by concentrated friction.

[0043]The lower end of the slider 2 is a W-shaped structure. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com