Finned heat exchanger and refrigeration equipment

A fin-type heat exchanger and fin technology are applied in the fields of refrigeration equipment and fin-type heat exchangers, which can solve the problems of complicated processing technology and high cost of internal threaded pipes, and achieve the improvement of pipeline arrangement rate, The effect of improving reliability and increasing length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

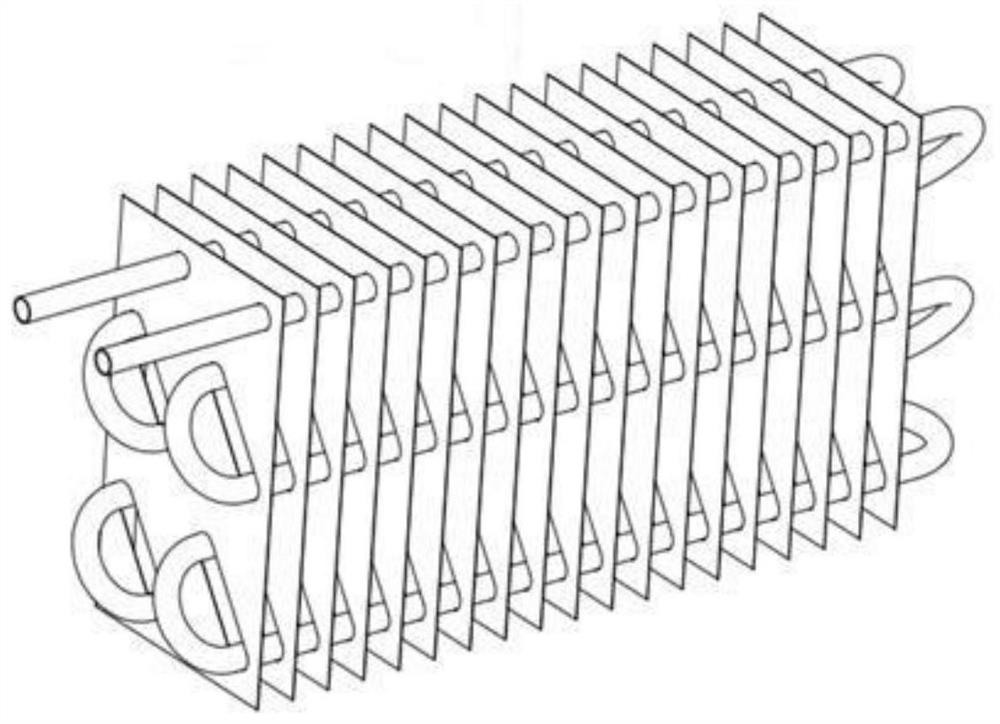

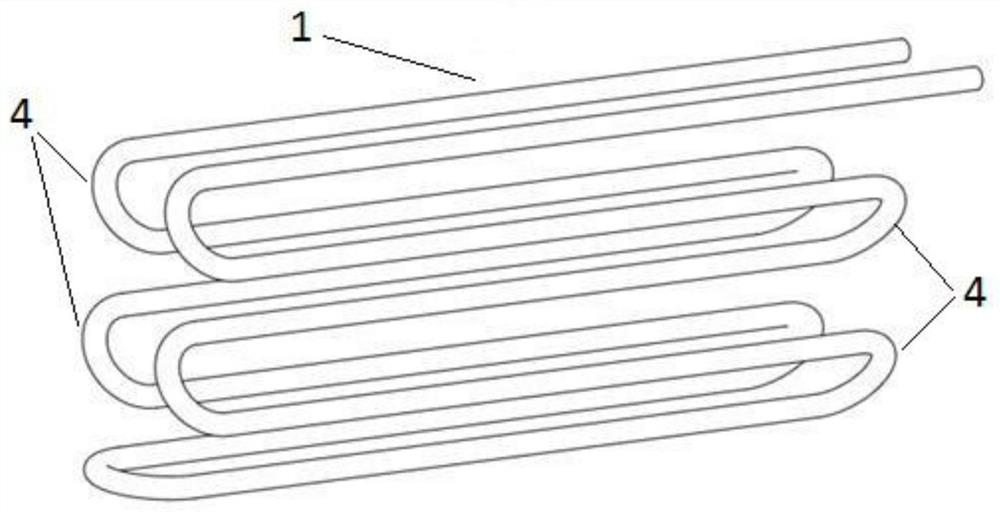

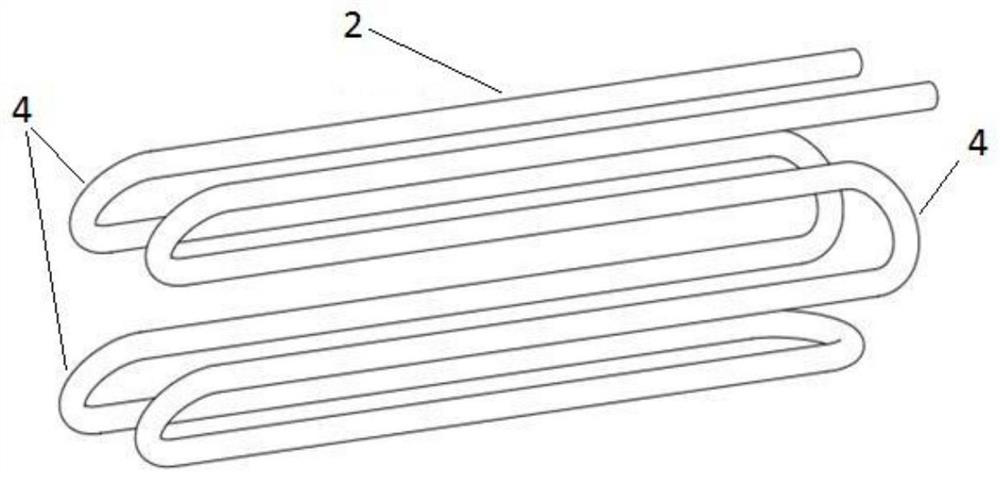

[0041] According to the first object of the present invention, this embodiment provides a finned heat exchanger, such as Figure 2-7 As shown, it includes a set of fins and two heat exchange tubes, and the set of fins is composed of several fins 3 arranged in parallel and at a certain distance from each other. The heat exchange tube is one of aluminum tubes, copper tubes, and steel tubes, and its cross-sectional shape can be round, square, or oval, which can be selected according to different working environments and different needs. In this embodiment, it is a round aluminum tube . The two heat exchange tubes are the first heat exchange tube 1 and the second heat exchange tube 2 respectively, and each of the heat exchange tubes is bent and formed integrally. The U-shaped surface is defined as the reference surface, and after a certain distance from the bottom of the U-shaped opening along the U-shaped opening extension direction, it is bent upwards at an angle a relative to ...

Embodiment 2

[0046] This embodiment is the result of replacing it on the basis of embodiment 1. Such as Figure 8 As shown, the connector is a U-shaped connecting pipe 8, and the inlet of the first heat exchange tube 1 and the outlet of the second heat exchange tube 2 communicate through the U-shaped connecting pipe 8 to form a single-pipe refrigeration pipeline , which effectively increases the length of the refrigeration pipeline and improves the heat exchange efficiency.

Embodiment 3

[0048] This embodiment is the result of replacing it on the basis of embodiment 1. Such as Figure 9 As shown, the first heat exchange tube 1 and the second heat exchange tube 2 are independent of each other and serve as refrigeration pipelines of two sub-refrigeration systems respectively. In the same space, the refrigeration system is equipped with two independent sub-refrigeration systems. On the one hand, you can choose to start refrigeration at the same time to increase the cooling speed of the product; or only choose one of them to start refrigeration according to the actual situation to achieve energy saving; When one of the sub-refrigeration systems fails, the other can ensure the continuation of refrigeration, improving the reliability of the entire refrigeration system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com