Multi-level whole-process monitoring method for power equipment

A technology of electric equipment and the whole process, applied in the direction of electrical digital data processing, instruments, data processing applications, etc., can solve the problems of inability to intuitively control primary equipment, low degree of integration of physics and information, and insufficient monitoring methods, so as to improve equipment perception effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

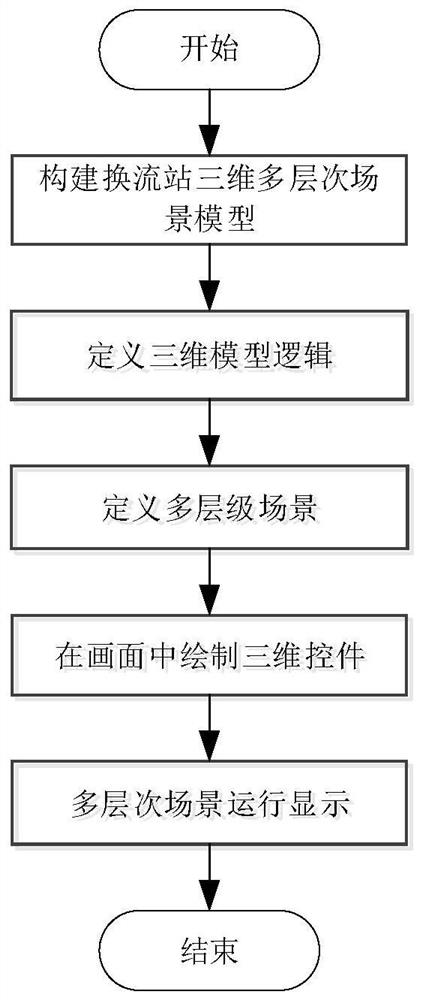

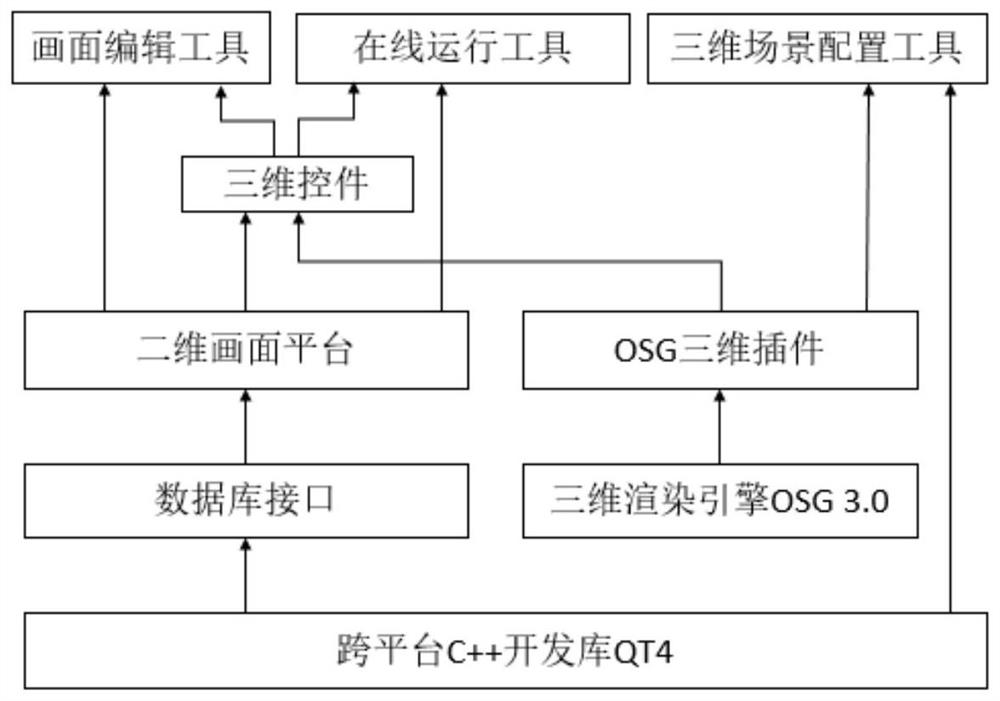

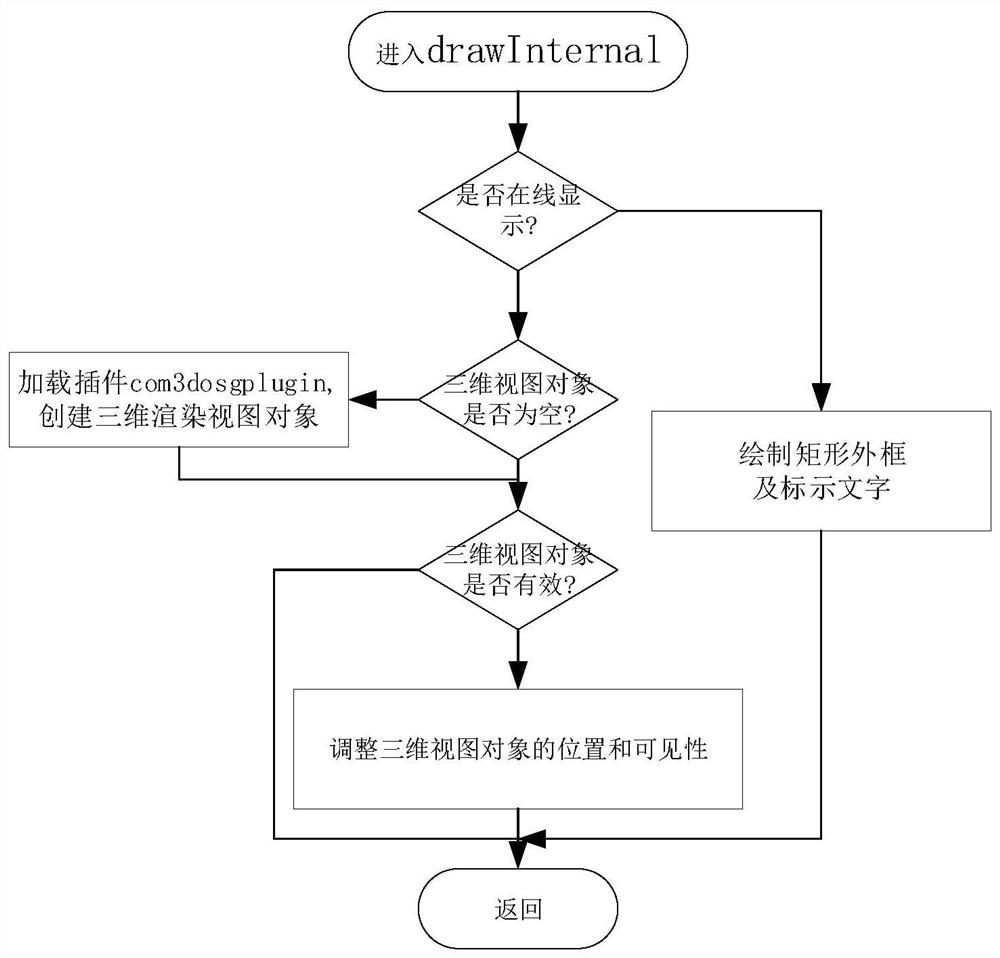

[0027] Such as figure 1 As shown, the present invention takes the converter station equipment in the power equipment as an example of the monitoring object, and proposes a multi-level whole-process monitoring method for the converter station. Based on the traditional two-dimensional screen and embedded three-dimensional controls, the multi-level Steps such as 3D scene model, definition of 3D equipment model logic, definition of multi-level 3D scene model, drawing of 3D controls in 2D screen, and operation and display of multi-level 3D scene model, realize multi-level scene switching and variable transfer, and build , DC field, converter valve, AC field, main control room to the 2D and 3D whole-process 3D monitoring screen of a single device, using intuitive 3D display of equipment electrical and status data, so as to facilitate the intuitive display of equipment inform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com