A multi-layer board with v_cut depth detection by electrical test

A deep detection, multi-layer board technology, applied in the direction of circuit inspection/identification, printed circuit, electrical components, etc., can solve the problems of increased rework rate, inability to divide the board, increase the workload of workers, etc., achieve accurate V_CUT depth control, avoid The trouble of line width and spacing detection, the effect of avoiding production rework or scrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] For a four-layer multilayer board, the thickness of the board is required to be 2.0mm. In order to ensure the interlayer thickness, the thickness of the core board is required to contain a copper core board of 0.5mm. According to the requirements of the V-CUT sub-board, the V_CUT excess thickness should be controlled at 0.5-0.7mm, to ensure that the board can be accurately divided and the board is not easy to break. Therefore, according to the requirements, the board thickness is 2.0mm, and the thickness of the finished board after lamination should be controlled within the range of 1.9mm+ / 10%mm. Therefore, it is necessary to use a multi-layer core board or a multi-layer PP sheet laminate structure.

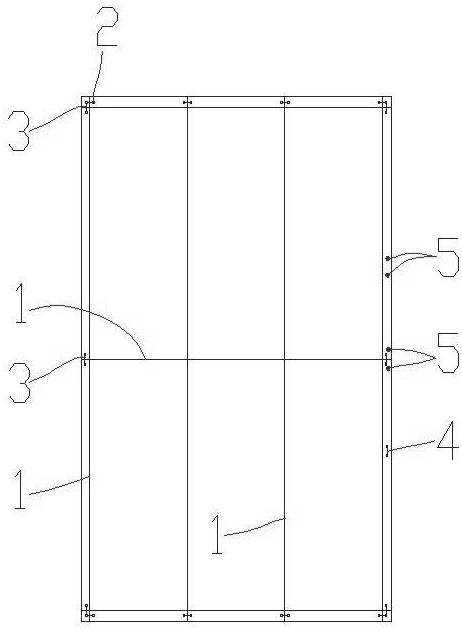

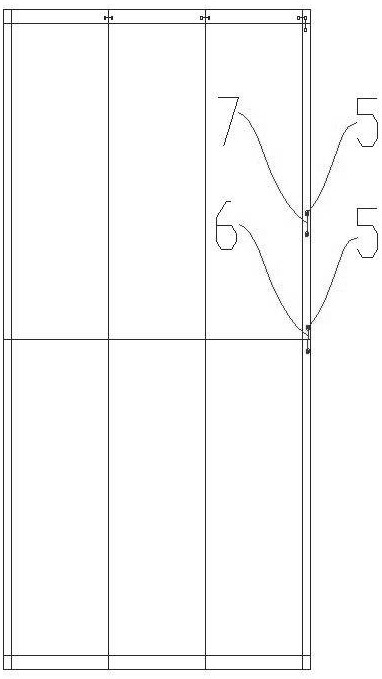

[0034] Add test terminals 2 and terminal connection lines 3 on the outer layer of the multilayer board to ensure that the electrical test can accurately confirm whether V_CUT is leaking. In the laminated structure, at 0.6+ / -0.1mm of the laminated layer Copper foil is place...

Embodiment 2

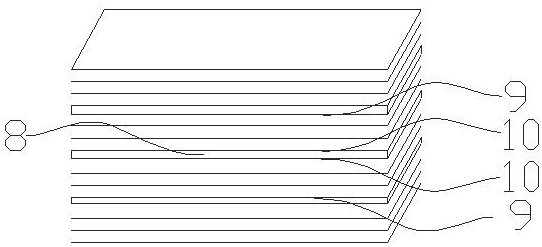

[0038] refer to image 3 , for a multi-layer board with more than six layers, the number of core boards and PP sheets is large, and there are many types of laminated structure adjustments. Taking the eight-layer board thickness requirement of 2.0mm as an example, according to the requirements, the board thickness is 2.0mm. After pressing, the thickness of the finished board should be controlled within the range of 1.9mm+ / 10%mm. According to the requirements of V-CUT board splitting, the V_CUT excess thickness should be controlled at 0.5-0.7mm to ensure accurate board splitting and not easy to break the board.

[0039] The eight-layer board needs three core boards and at least three PP sheets at the same time, which provides a variety of laminated structures. In order to ensure the thickness between layers, the thickness of the middle core board 8 is controlled according to the copper content of 0.4mm, and the remaining two The core boards are controlled at 0.3mm respectively, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com