An environmentally friendly waste glass bottle crushing and recycling equipment

A technology for recycling equipment and glass bottles, applied in the field of machinery, can solve the problems of insufficient crushing, complex structure, huge volume, etc., and achieve the effect of prolonging service life, improving efficiency and saving time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The environmentally friendly waste glass bottle crushing and recycling equipment of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

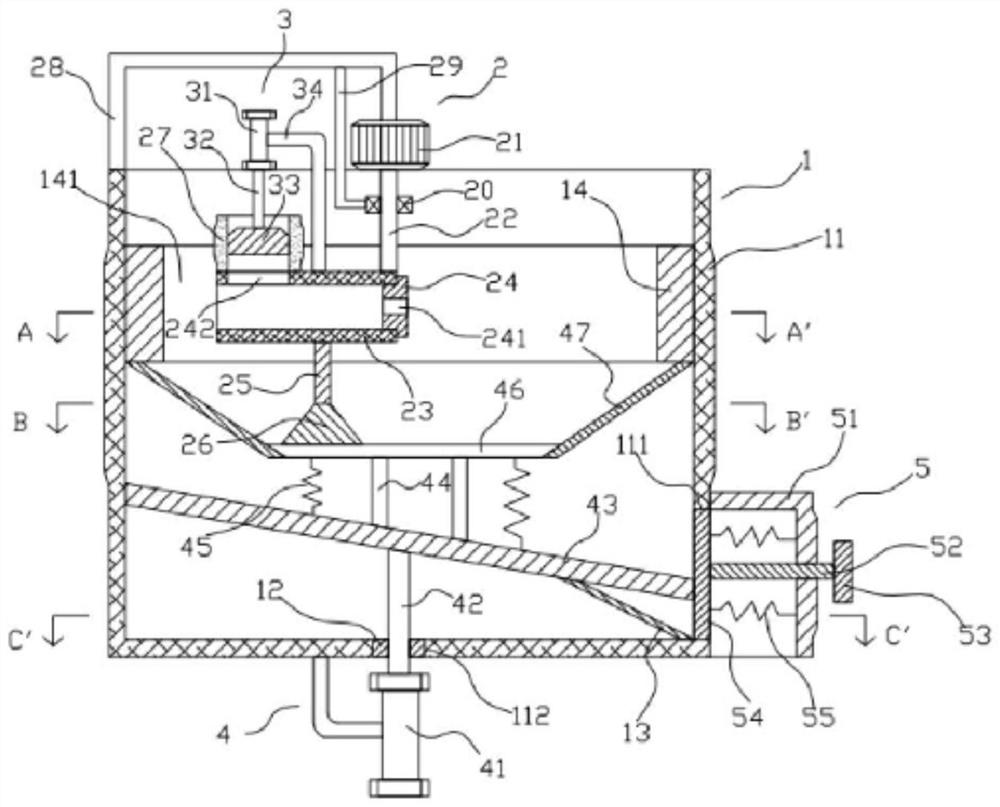

[0022] Such as Figure 1 to Figure 4 As shown, the environmentally friendly waste glass bottle crushing and recycling equipment of the present invention includes a shell structure 1, a rotating frame structure 2 arranged in the shell structure 1, a crushing structure 3 arranged on the rotating frame structure 2, and a The lifting structure 4 below the rotating frame structure 2 and the baffle structure 5 arranged outside the shell structure 1 .

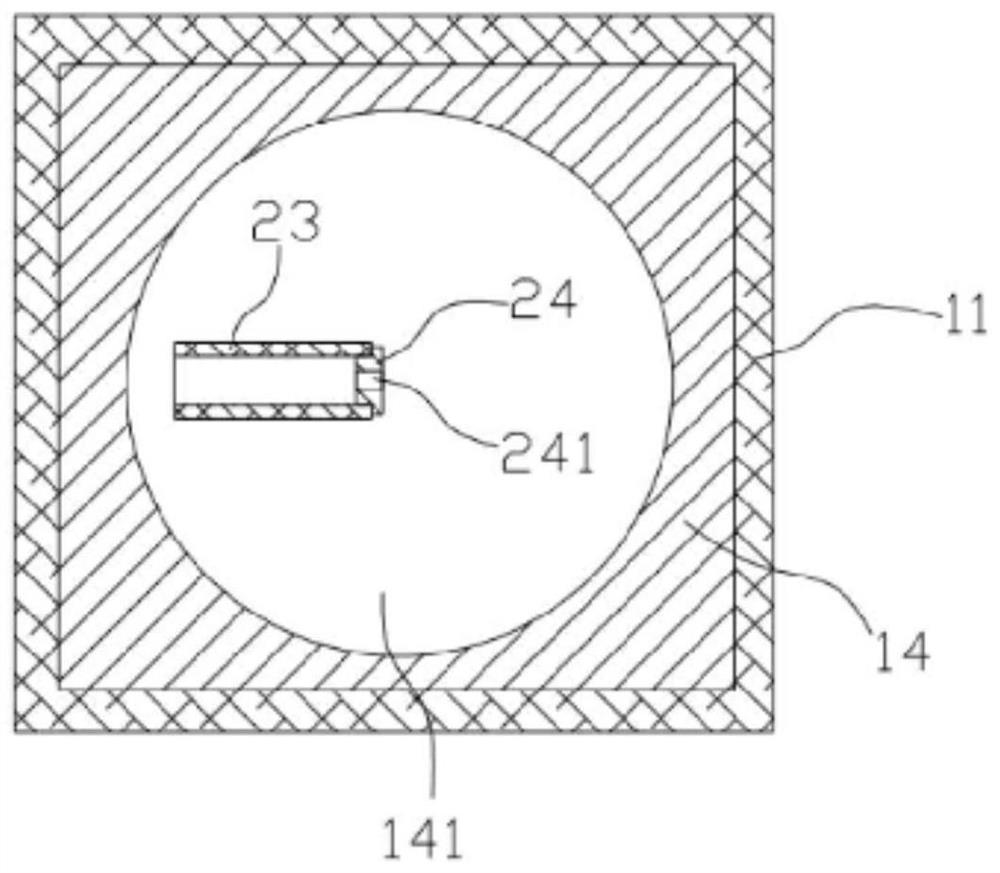

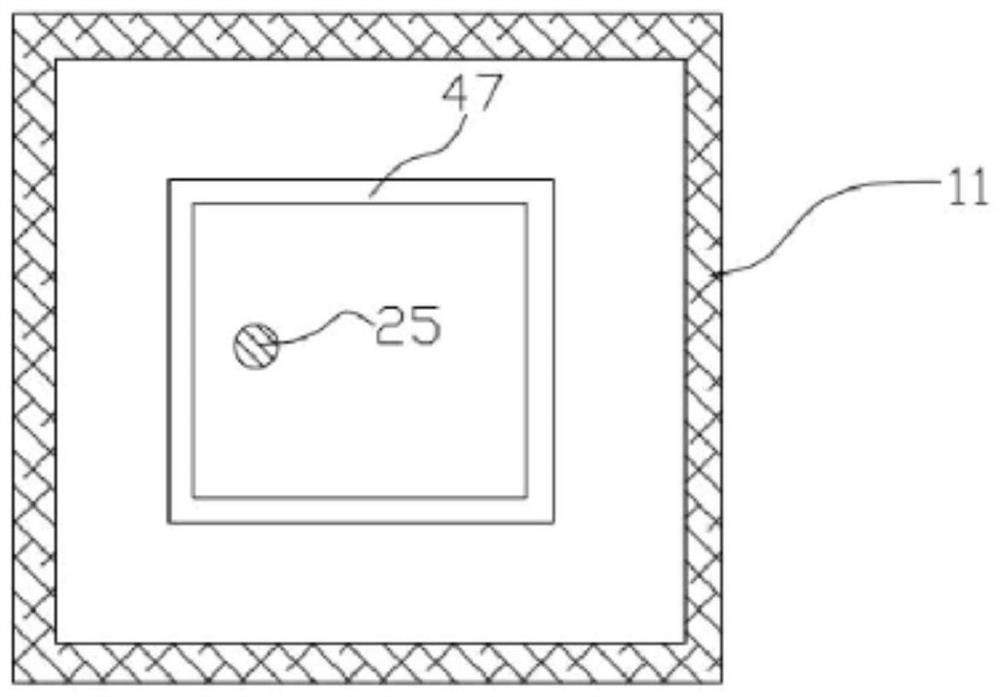

[0023] Such as Figure 1 to Figure 4 As shown, the housing structure 1 includes a housing 11, a smooth block 12 disposed on the lower wall of the housing 11, an elastic plate 13 disposed on the bottom surface of the inner cavity of the housing 11, and an elastic plate 13 disposed above the elastic plate 13. The focus box 14. D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com