Nodular cast iron cooling device

A technology of ductile iron and cooling water tank, which is applied in the field of cast iron, can solve the problems that the cooling water tank cannot be replaced, inconvenient to use, and reduce the cooling effect, so as to avoid the continuous rise of water temperature, facilitate picking and placing, and have obvious cooling effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

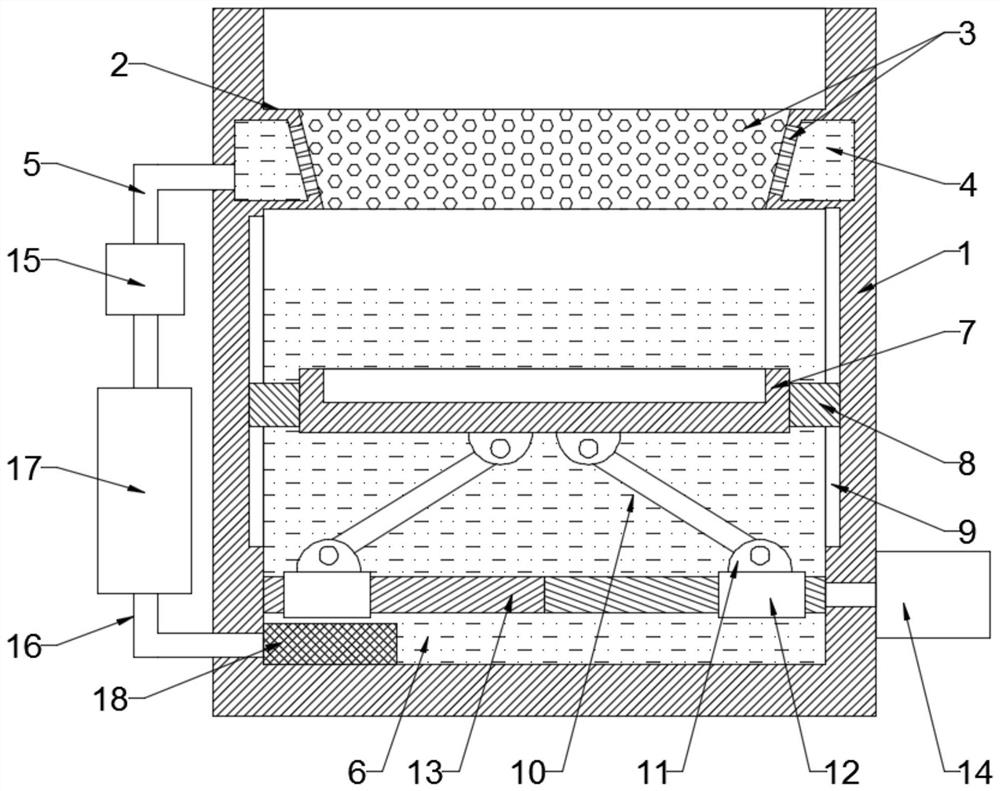

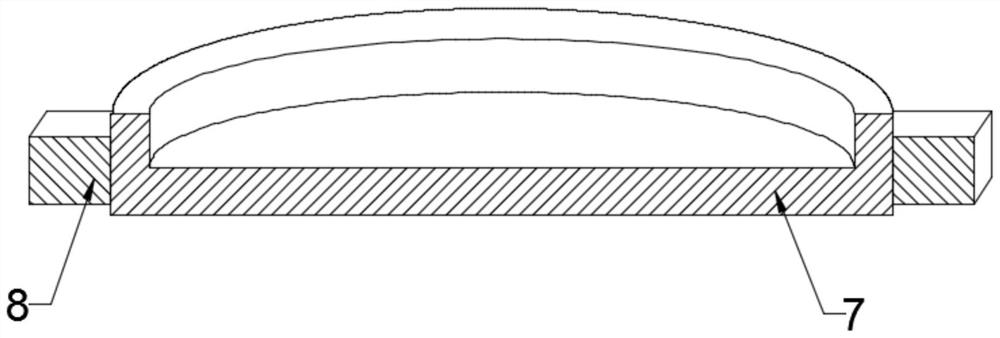

[0023] see Figure 1 ~ Figure 3 , a device for cooling ductile iron, including a cooling water tank 1, a water spray platform 2, a bearing platform 7 and a circulating water pipe 16, the interior of the cooling water tank 1 is set for cooling the ductile iron, and the cooling water tank 6, the cooling water tank 6 is provided with a bearing platform 7, and the middle part of the bearing platform 7 is provided with a slot for placing nodular cast iron. The outer side of the bearing platform 7 is connected with a slider 8, and the slider 8 is slidably arranged along the chute 9 on the inner wall of the cooling water tank 1. Wherein, the bottom of the bearing platform 7 is connected to one end of the diagonal strut 10 through the hinge seat 11, and the other end of the diagonal strut 10 is hinged to the shaft sleeve 12, and the shaft sleeve 12 is screwed to the lead screw 13, and the lead screw 13 is installed on the cooling In the water tank 1, the lead screw 13 is connected to ...

Embodiment 2

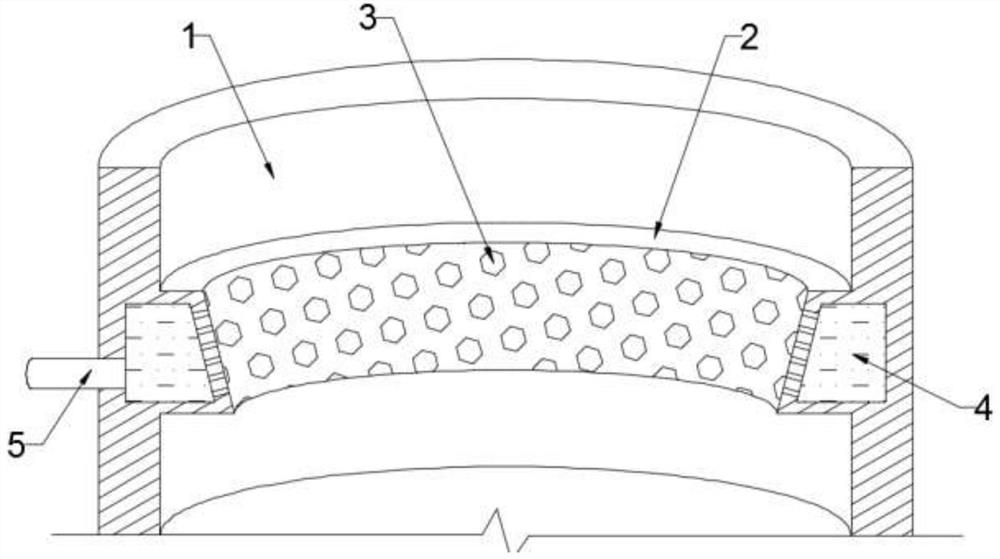

[0028] see Figure 1 ~ Figure 3 , a device for cooling ductile iron, including a cooling water tank 1, a water spray platform 2, a bearing platform 7 and a circulating water pipe 16, the interior of the cooling water tank 1 is set for cooling the ductile iron, and the cooling water tank 6, the cooling water tank 6 is provided with a bearing platform 7, the cooling water tank 1 upper inner wall is provided with a water spray platform 2, and the inner surface of the water spray platform 2 is provided with a number of water spray holes 3, and the water spray holes 3 and the uniform water inside the water spray platform 2 The chambers 4 are connected, and the uniform water chamber 4 is connected to the water inlet pipe 5 .

[0029] In the embodiment of the present invention, a spray pipe can also be provided above the cooling water tank 1, the spray pipe is connected to the water inlet pipe 5, and the spray head of the spray pipe is arranged above the slot of the carrying platform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com