Laser cutting method for dimming film or electrode thereof

A technology of laser cutting and dimming film, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of inability to produce sheet products, unevenness, burrs, etc., and achieve large-scale engraving/cutting production , The effect of small cutting size error and fast cutting efficiency

Inactive Publication Date: 2021-01-08

ZHUHAI SINGYES NEW MATERIALS TECH CO LTD

View PDF26 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

But the problem is that these devices are still hand-cut when making dimming film electrodes, so many problems will arise

For example, if the operator is not skilled, and the electrode length > 1000mm, the electrode width will often be cut unevenly; in addition, the electrode made with a cutter will have burrs and unevenness in the cutting part, resulting in the failure to improve product quality ; Also, the efficiency of manually cutting electrodes is very low, and it is impossible to produce large-scale sheet products

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

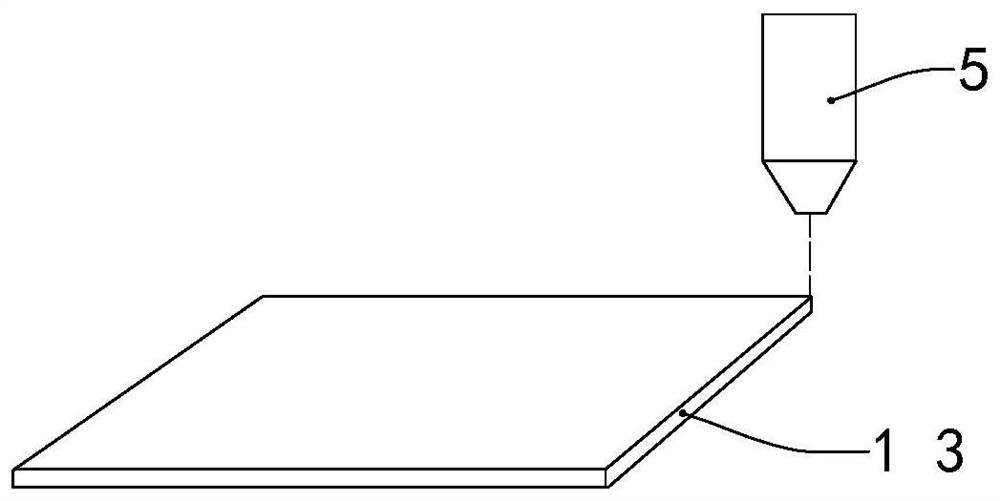

[0040] One-time cutting: select the transmitter with a laser power of 60W, and use CO 2 Laser transmitter, the cutting speed is 800mm / s, the air pressure is nitrogen, and the outlet pressure is 1MPa for cutting.

Embodiment 2

[0042] Multiple cutting: In order to ensure that the PET upper layer of the product electrode is cut and separated, multiple cutting methods can be used.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

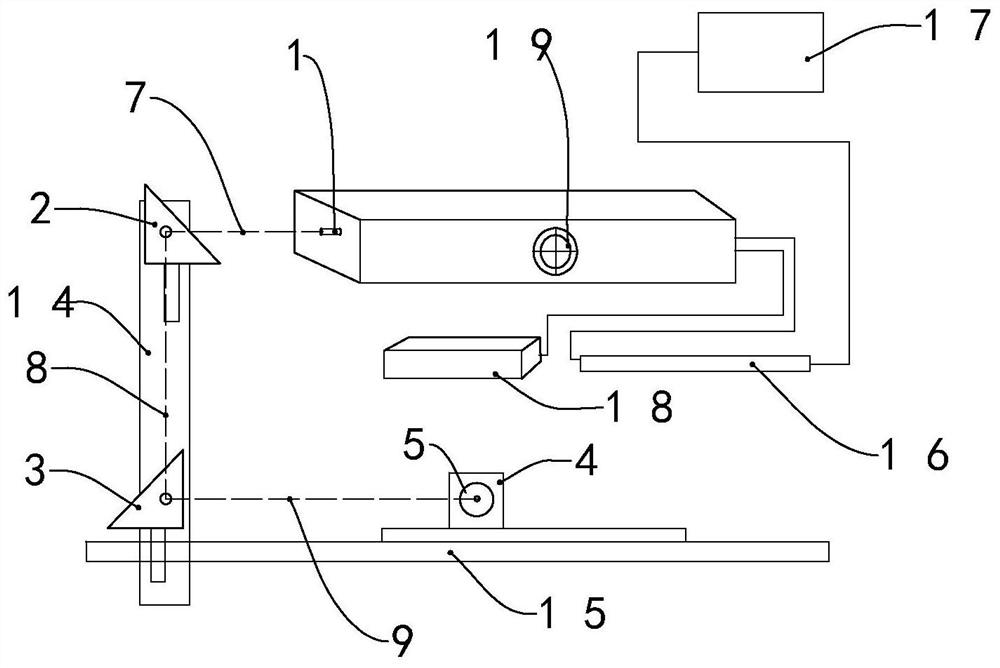

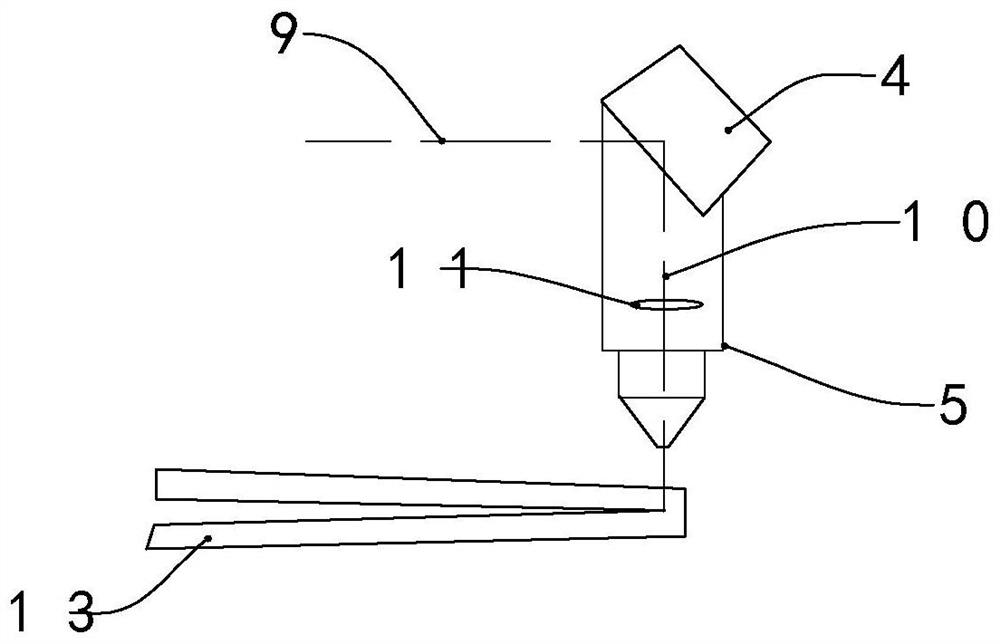

The invention relates to a laser cutting method for a dimming film or an electrode thereof. The method is implemented on a laser cutting device, and the laser cutting device comprises a laser emitter,a first steering mirror, a second steering mirror, a third steering mirror and a laser head. The method comprises the steps that the dimming film or the electrode of the dimming film is placed on a cutting table top; and the laser emitter is started, the second steering mirror moves along a second light path and / or the third steering mirror moves along a third light path, so that laser emitted from the laser head cuts the dimming film or the electrode of the dimming film along a preset cutting line, and the preset cutting line is a straight line, a multi-line segment and / or a curve. According to the laser cutting method, various cutting shapes of the dimming film or the electrode thereof can be realized, and the cutting error is small.

Description

technical field [0001] The invention relates to the field of dimming film production, in particular to a method for manufacturing a dimming film or an electrode thereof by laser cutting. Background technique [0002] In recent years, with the development of liquid crystal technology, more intelligent color-changing films have been researched and developed. Among them, the most common intelligent dimming films are electrochromic dimming films and thermochromic dimming films. Among them, the electrochromic light film products need to make electrodes and connect to the power supply before they can be used normally. The electrodes include OCA conductive film, ITO conductive film or nano-silver conductive film, etc., and are usually formed by electroplating and depositing conductive materials on plastic films such as PET films. In order to prepare a dimming film of the required size, it is usually necessary to cut the electrode, and now the electrode knife is basically used to ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23K26/38

CPCB23K26/38

Inventor 陈焙才李国增吴琴

Owner ZHUHAI SINGYES NEW MATERIALS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com