A computer-controlled ship anchor

A computer and anchor technology, applied in the field of computer-controlled anchors, can solve the problems of long distance between the hull and the anchor, dangers and hidden dangers of the hull, etc., and achieve the goal of preventing loose fixation, improving the degree of fixation, and improving grip Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

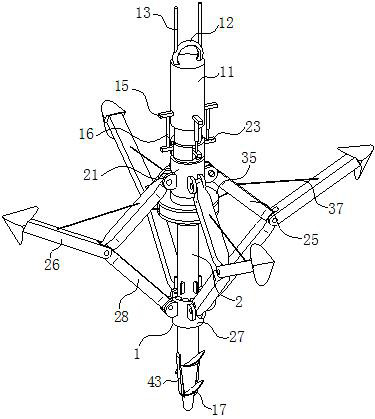

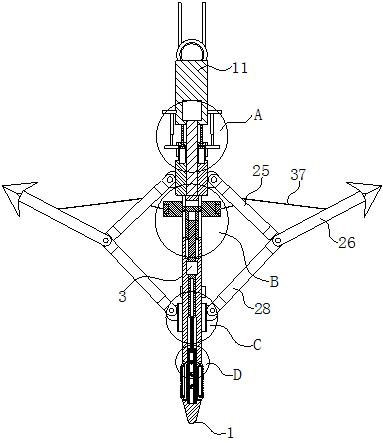

[0030] Example 1, such as Figure 1-Figure 7 As shown, a computer-controlled ship anchor according to the present invention includes an anchor body 1; the anchor body 1 includes a driving rod 11; a hanging ring 12 is fixedly connected to the inner wall of the driving rod 11 above the driving rod 11 A rope 13 is installed on the hanging ring 12, and the number of the rope 13 is two; a first motor 14 is installed in the inner wall of the drive rod 11, and the first motor 14 is connected with a computer signal through a controller; A connecting rod 2 is fixedly connected to the drive shaft of the motor 14; an auxiliary ring 21 is rotationally connected to the outer surface of the connecting rod 2 under the driving rod 11; the first support plate 15 evenly arranged is fixed on the outer surface of the driving rod 11; The inner wall of the auxiliary ring 21 is provided with uniformly arranged first chute 22, and a second support plate 23 is slidably connected in the first chute 22;...

Embodiment 2

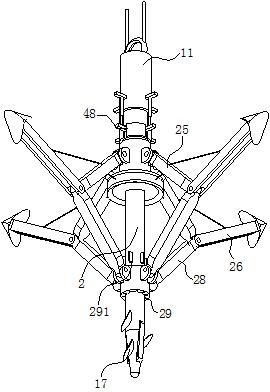

[0032] Embodiment 2 is different from Embodiment 1 in that a second motor 3 is fixedly connected to the inner wall of the connecting rod 2 below the auxiliary ring 21, and the second motor 3 is connected to the computer signal through the controller; the second motor 3 is a double-headed motor; the drive shaft above the second motor 3 is fixedly connected with a first lead screw 31; a second chute 32 is provided above the first lead screw 31, and slides in the second chute 32 A first jacking block 33 is connected; the first jacking block 33 is connected to the first lead screw 31 through threads; the outer side of the first jacking block 33 is provided with a third chute 34 evenly arranged in the inner wall of the connecting rod 2; The first jacking block 33 is fixedly connected with a support ring 35 through evenly arranged connecting rods, and the support ring 35 is slidably connected with the connecting rod 2;

[0033] When working, when the anchor body 1 is screwed into th...

Embodiment 3

[0034] Embodiment 3, different from Embodiment 2, is that a collar 36 is connected to the inner wall of the support ring 35 through ball rotation; the inner wall of the collar 36 is fixed with evenly arranged stay ropes 37, and the stay ropes 37 are all Made of metal material; the other end of each stay rope 37 passes through the first anchor rod 25 and is fixedly connected with the second anchor rod 26;

[0035] During work, because the collar 36 that is rotatably connected in the inner wall of the brace ring 35 is fixedly connected with the second anchor rod 26 by the stay cord 37, when the connecting rod 2 drives the brace ring 35 to rotate, the collar 36 will be in the brace ring 35. Rotation occurs, so as to prevent the stay rope 37 from being entangled with the first anchor rod 25. When the anchor body 1 needs to be retracted, the computer controls the second motor 3 to rotate clockwise. During the clockwise rotation of the second motor 3, it can Drive the first jacking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com