Cloth inspecting machine of scutcher

A fabric inspection machine and open-width machine technology, which is used in thin material processing, optical testing for flaws/defects, sending objects, etc., can solve problems such as low production efficiency and cumbersome steps, improve production efficiency, save complex steps, The effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in further detail below:

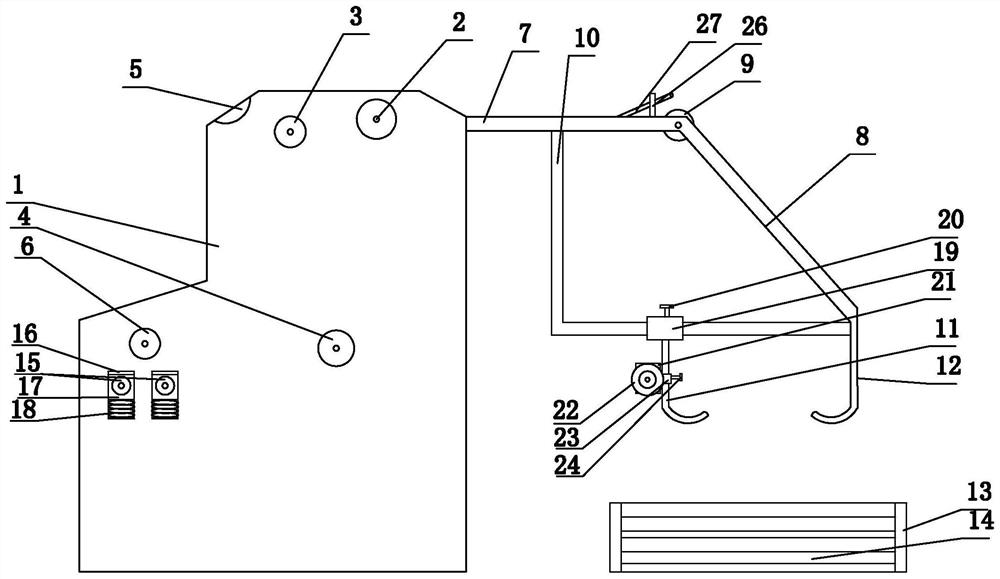

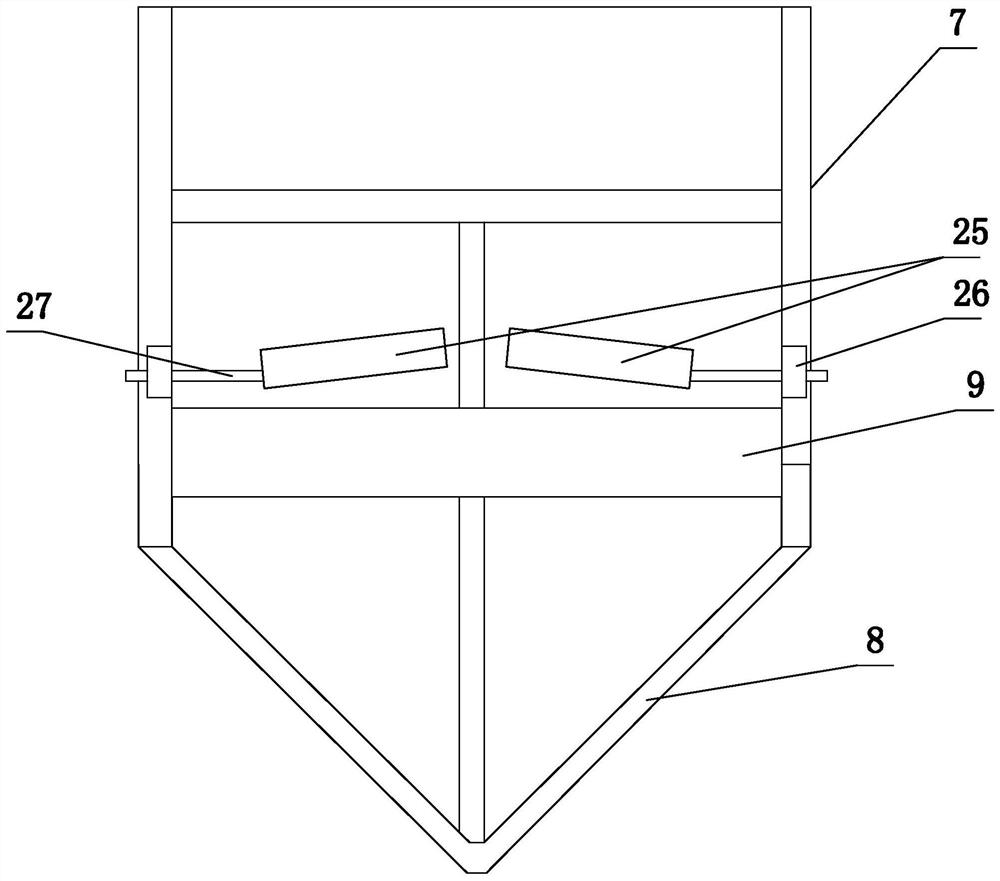

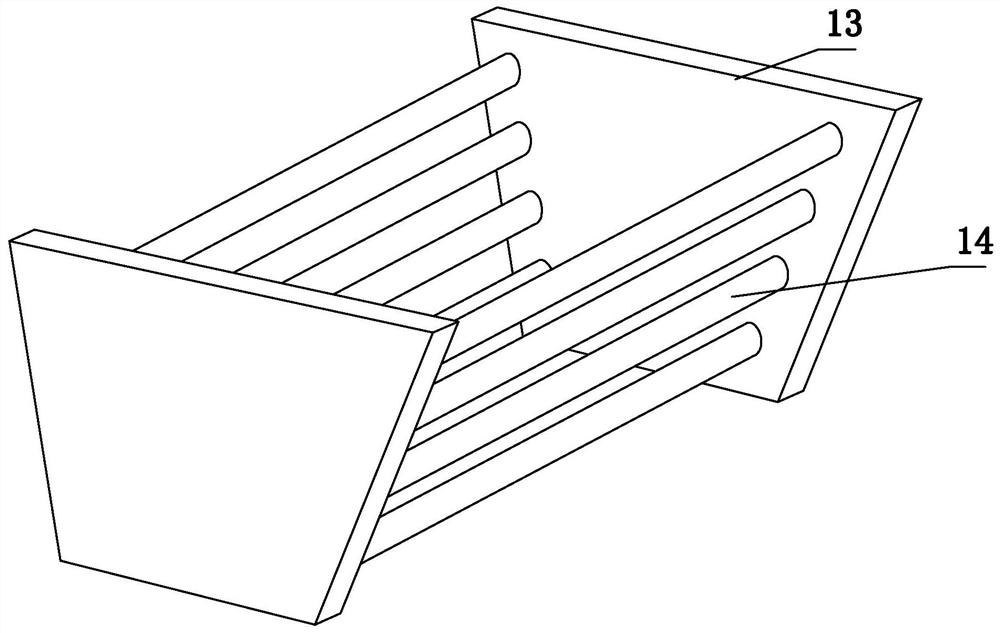

[0021] An open-width machine cloth inspection machine, comprising a cloth inspection table 1, an opening device arranged on the rear side of the cloth inspection table 1, and a feeding rack arranged under the opening device, the cloth inspection table 1 is provided with a first Material guide roller 2, the second material guide roller 3, the third material guide roller 4, the cloth inspection lamp 5, the winding roller 6 and the first drive motor, the first material guide roller 2 and the second material guide roller 3 are arranged on the inspection The upper end of the cloth table 1, and the first material guide roller 2 is located behind the second material guide roller 3, and the third material guide roller 4 is arranged in the middle of the cloth inspection table 1, and is located between the first material guide roller 2 and the second material guide roller. Between the material rollers 3, the cloth insp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com