Lifting closure construction method for arch ribs of arch bridge

An arch rib and arch bridge technology, which is applied in the construction field of arch rib installation, can solve problems such as being unfavorable to the integrity of the arch rib and the wind bracing structure of the arch rib, the mutual interference between the construction of the arch rib section and the approach bridge, and the poor stability of the mid-section closing section. It is easy to control and adjust the elevation and alignment of the arch rib, shorten the construction period and make the alignment reasonable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

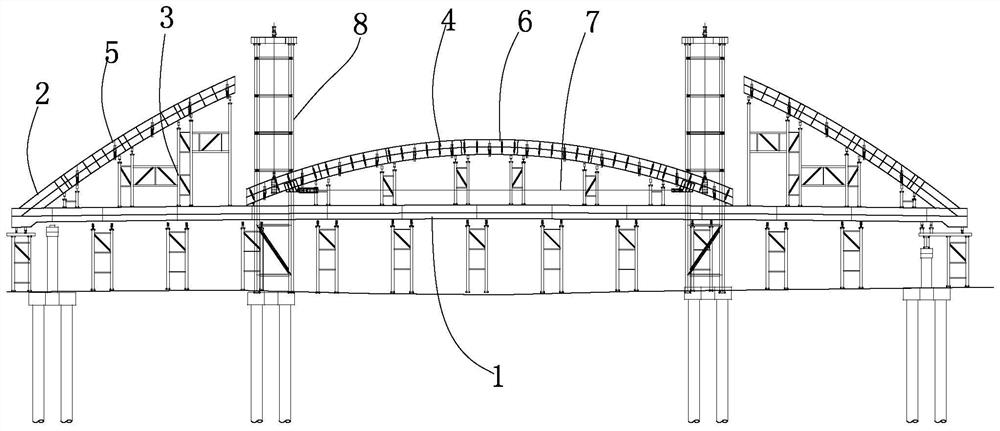

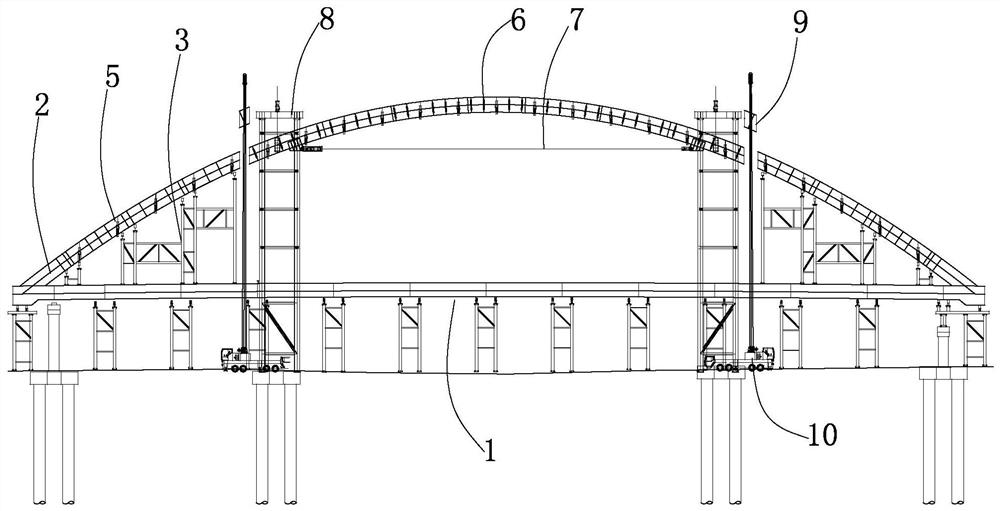

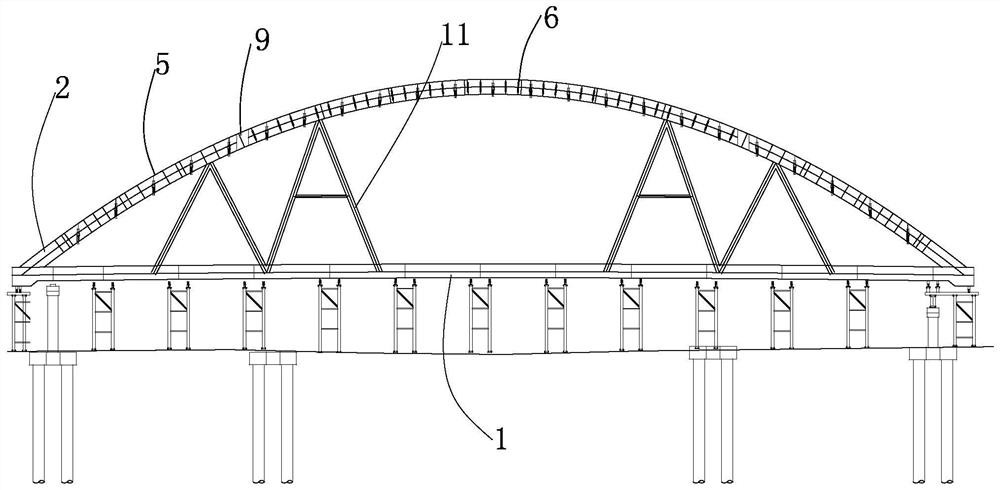

[0028] (1) The arch rib is divided into two arch rib sections, one arch rib lifting section, and two arch rib closing sections; one end of the arch rib section is connected to the arch foot through a hinge shaft, and the other end is connected to The hoisting section of the arch rib is connected; the length of the hoisting section of the arch rib is not less than 1 / 2 of the total length of the arch rib; the hoisting section of the arch rib and the arch rib section of the arch foot are assembled in segments.

[0029] (2) When hoisting the beam section of the bridge deck of the arch bridge, the installation of the hoisting frame in the lifting section of the arch rib in the subsequent process shall be considered during hoisting. When the position of the bridge deck system conflicts with the position of the hoisting frame, the beam section reserved for the lifting frame position may not be installed first.

[0030] Such as figure 1 As shown, after the installation of the bridge d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com