Shock wave focusing detonation combustion chamber based on multi-zone ignition

A technology of shock wave focusing and combustion chamber, which is applied to rocket engine devices, jet propulsion devices, machines/engines, etc., and can solve difficult-to-achieve and high-energy problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

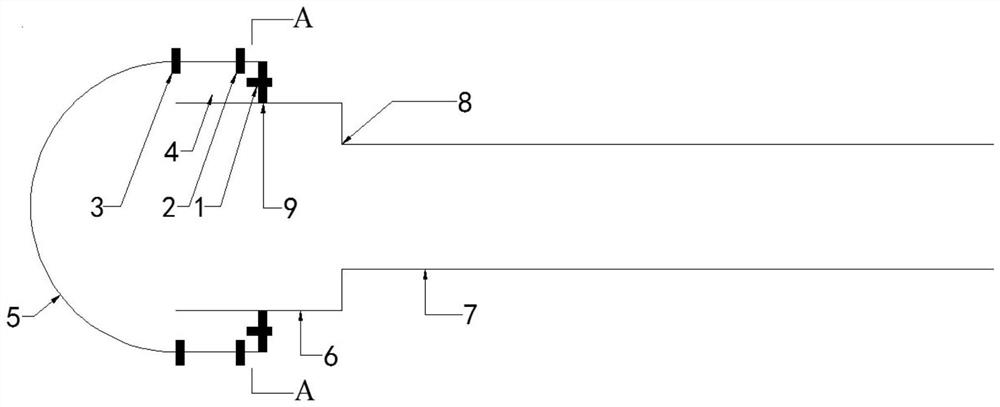

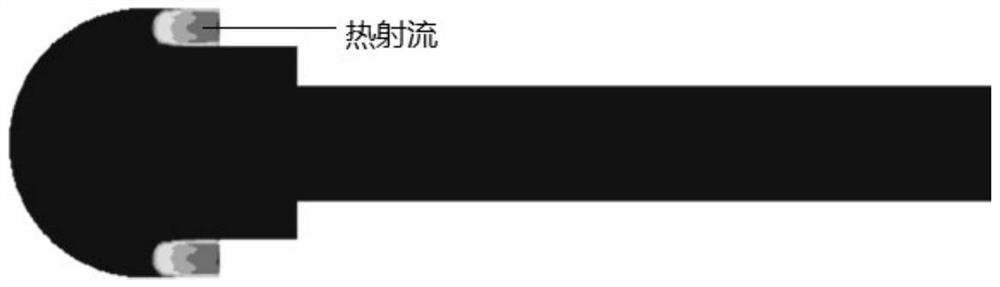

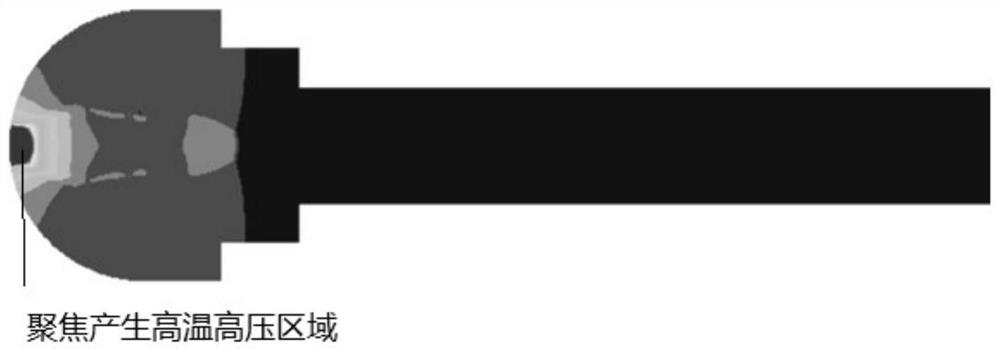

[0021] like figure 1 and image 3 As shown, the shock-focused detonation combustion chamber based on multi-zone ignition according to the present invention includes an air inlet 1, an igniter 2, a fuel nozzle 3, a pre-combustion chamber 4, a shock-wave focusing sphere 5, a detonation section 6, The main detonation combustion chamber 7, the sudden change in section 8 and the rotary valve 9. One end of the detonation section 6 is provided with a shock wave focusing sphere 5, and a number of pre-combustion chambers are evenly distributed on the outside of the detonation section 6, and the outlet of the pre-combustion chamber faces the tangential direction of the shock wave focusing sphere 5 for making The hot jet that each pre-combustion chamber produces is focused in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com