Double-valve-core programmable-control hydraulic valve adopting digital fluid pilot drive and control method thereof

A technology of programming control and double spools, which is applied in fluid pressure actuators, fluid pressure actuator system components, servo motor components, etc., can solve the problems of energy waste and the inability to independently adjust the valve inlet and outlet pressure, etc., to achieve Effects of reducing oil pressure disturbance, improving stability, and increasing working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further elaborated and described below in combination with specific embodiments. The technical features of the various implementations in the present invention can be combined accordingly on the premise that there is no conflict with each other.

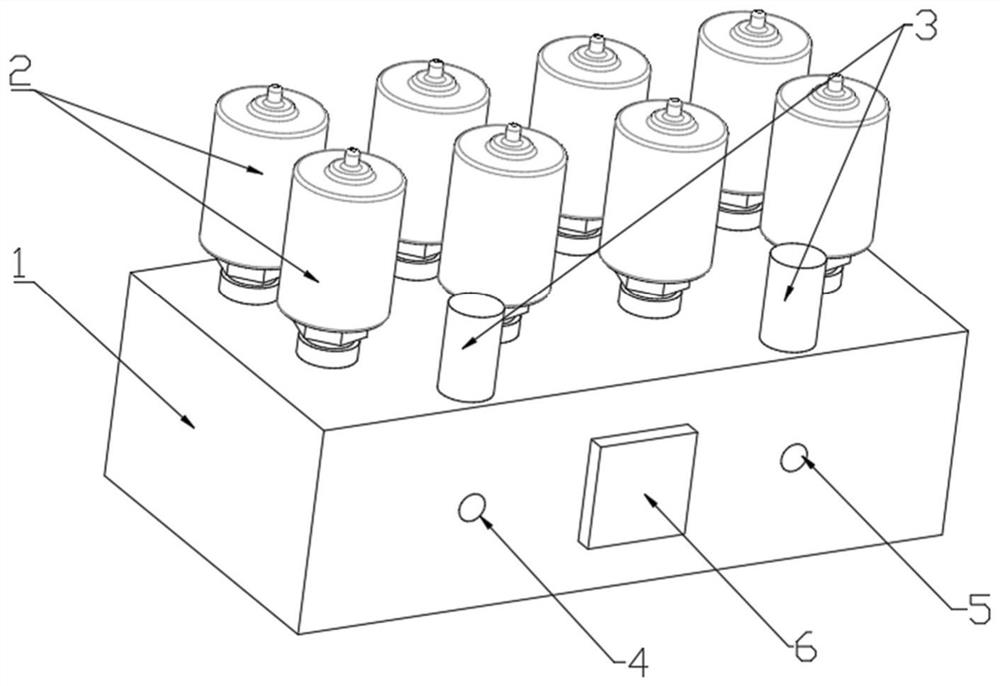

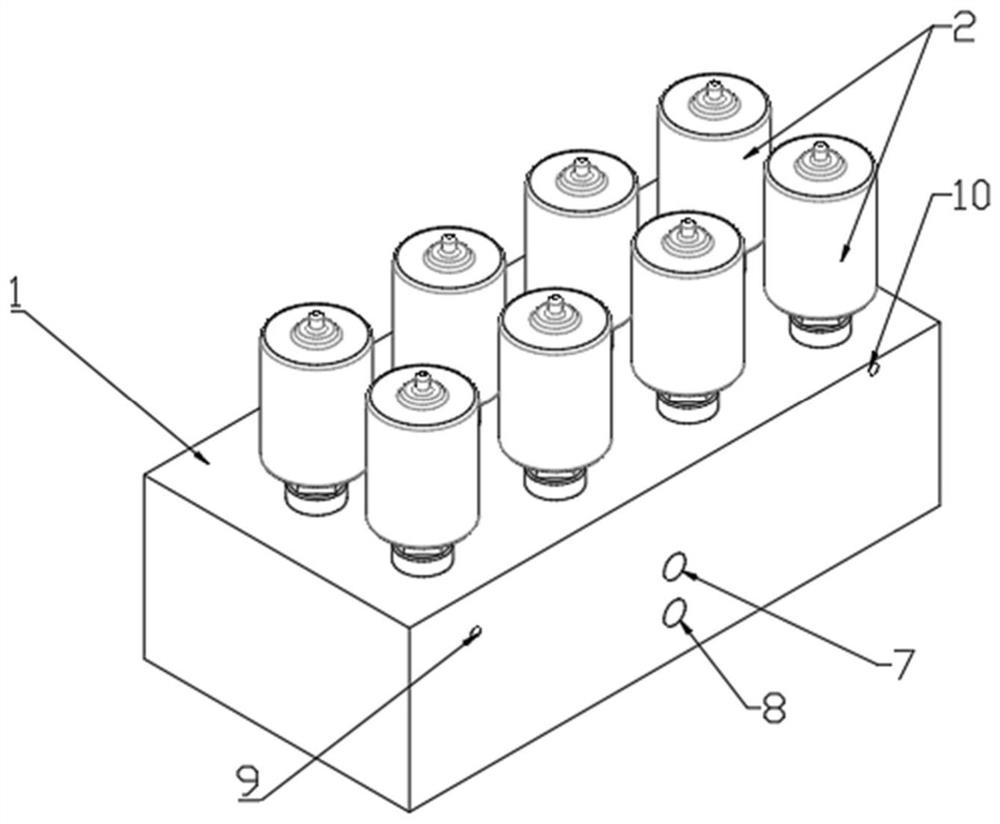

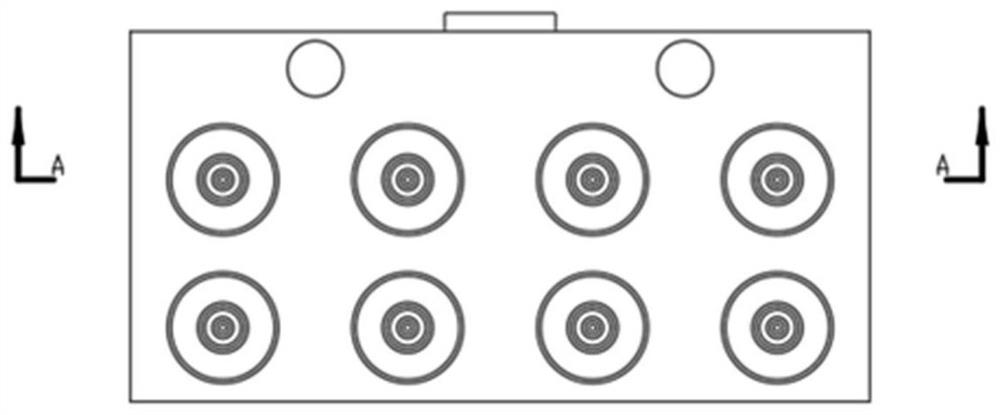

[0030] Such as Figure 1-5 As shown, the present invention discloses a digital fluid pilot-driven double-spool programmable control hydraulic valve, which includes a main valve body (1), eight high-speed switching valves, four one-way throttle valves and two three-position Three-way proportional valve; the two three-position three-way proportional valves are located in the main valve body (1), and 8 high-speed switching valves are installed on the main valve body; the main valve body (1) is provided with a main oil circuit P Port (7), main oil circuit T port (8), A port (4), B port (5), pilot oil circuit P port (9) and pilot oil circuit T port (10);

[0031] Port P (7) of the main oil circuit is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com