Concrete impermeability machine

A technology of concrete and pushing mechanism, applied in permeability/surface area analysis, measurement device, suspension and porous material analysis, etc., can solve the problems of low detection efficiency, troublesome steps, long time for replacement, etc. The effect of detecting efficiency, preventing bumps, and reducing the demand for venues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following is attached Figure 1-5 The application is described in further detail.

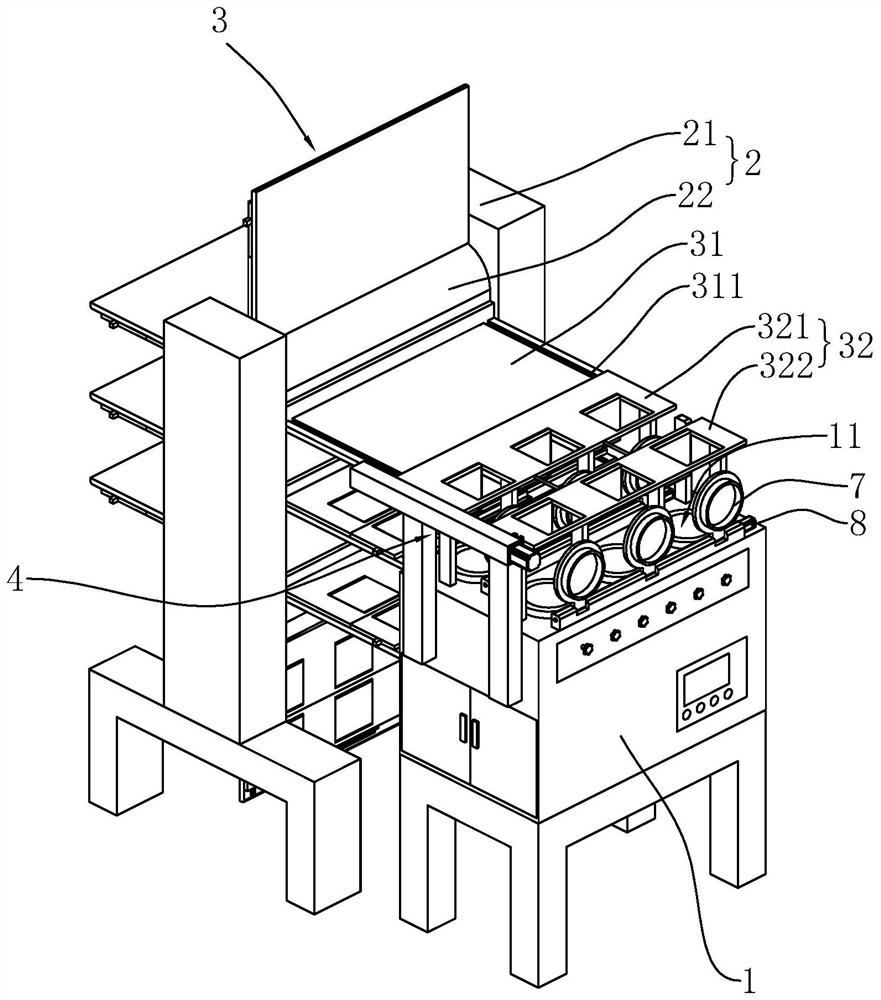

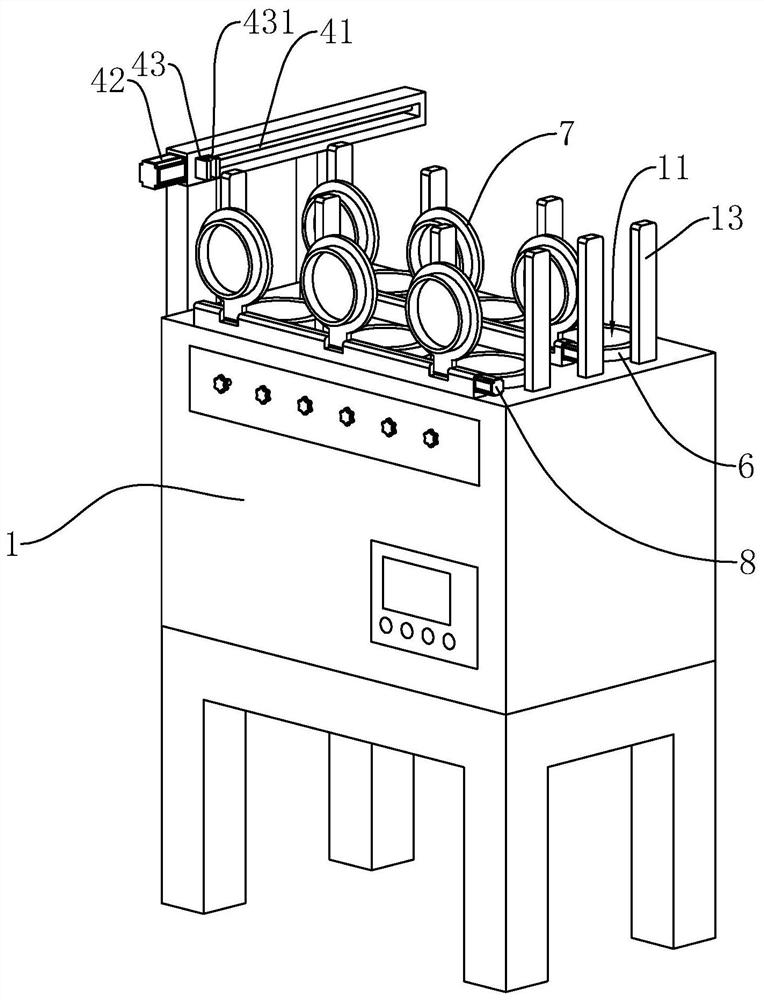

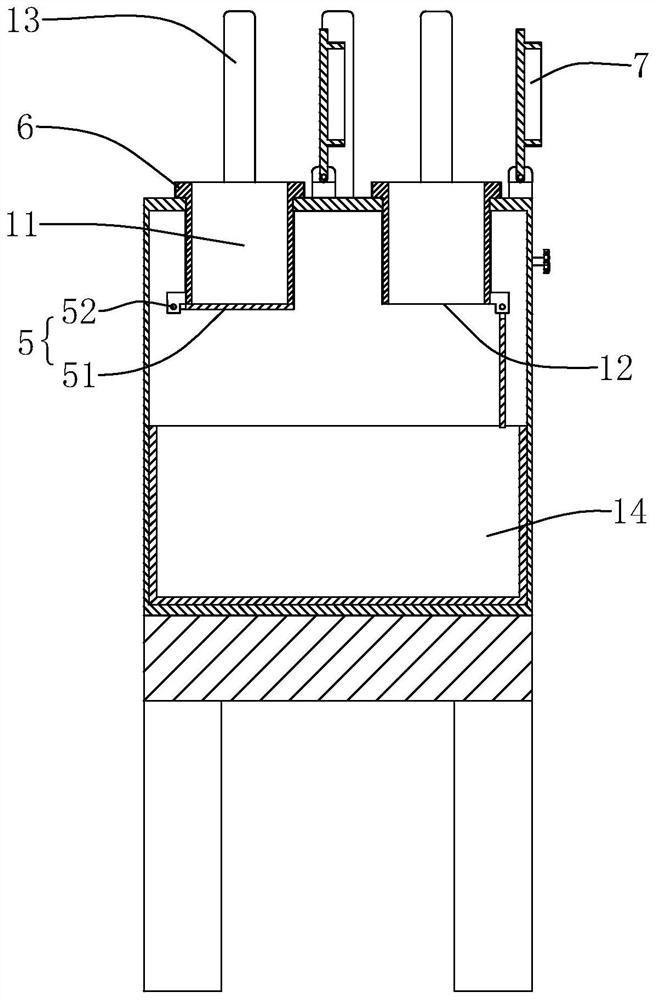

[0034] The embodiment of the present application discloses a concrete anti-seepage machine. refer to figure 1The concrete anti-seepage machine includes a detection box 1 and a step-by-step lifting mechanism 2. The top of the detection box 1 is provided with six detection grooves 11, and the six detection grooves 11 are divided into two groups of groove groups. The width direction is arranged sequentially, and the three detection grooves 11 in each groove group are distributed equidistantly along the length direction of the detection box 1 . The testing box 1 is provided with a pushing mechanism 4 on one end of the testing box 1 in the longitudinal direction. The gradual lifting mechanism includes a mounting frame 21 and a conveyor belt 22. The mounting frame 21 is on one side in the width direction of the testing box 1, and the top of the mounting frame 21 is higher than the top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com