A Quick Response Online Demagnetization Circuit for Bearing Rings

A bearing ring and quick response technology, which is applied in the field of bearing manufacturing, can solve the problems of poor demagnetization effect of the demagnetization device, and achieve the effects of good demagnetization effect, stable working performance and strong working reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

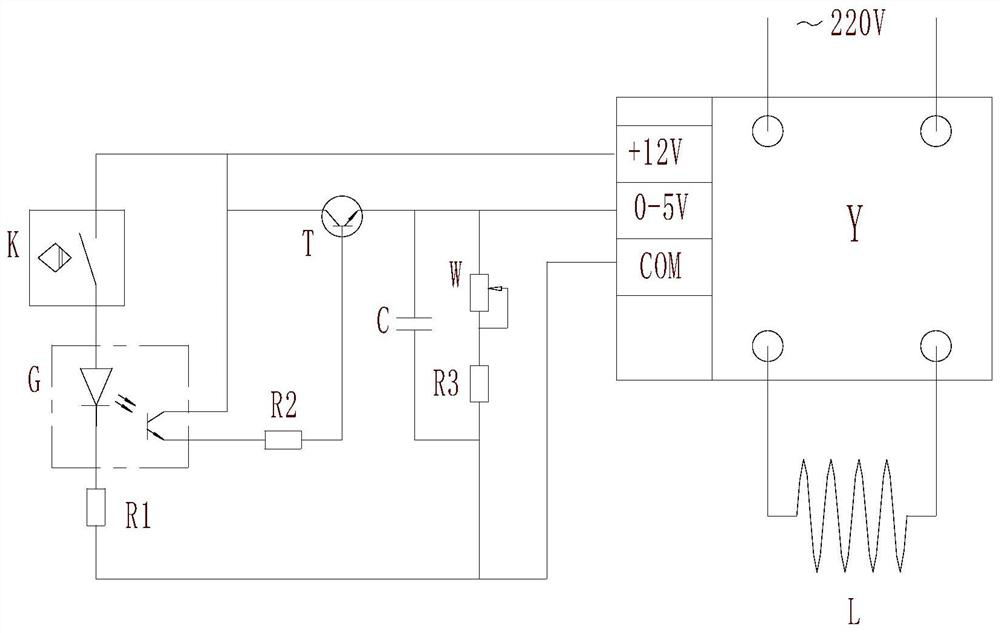

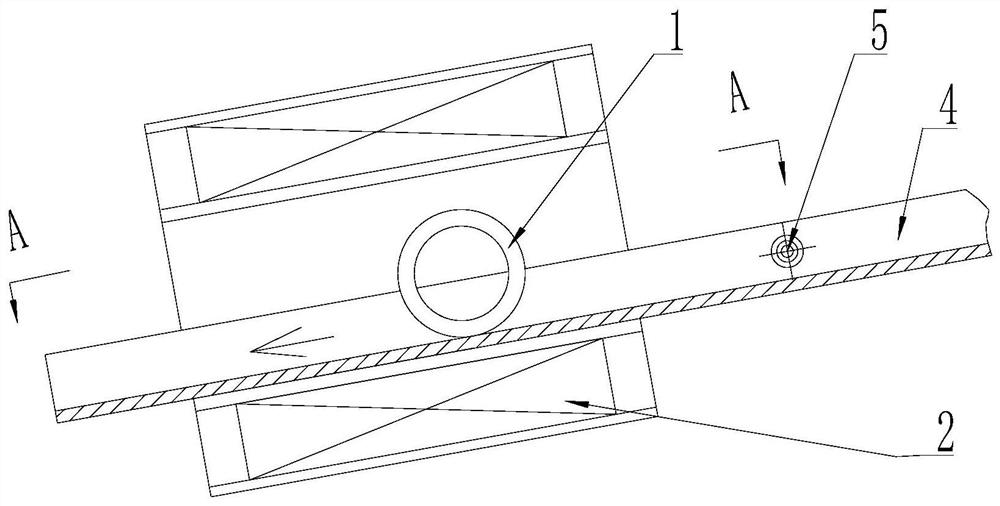

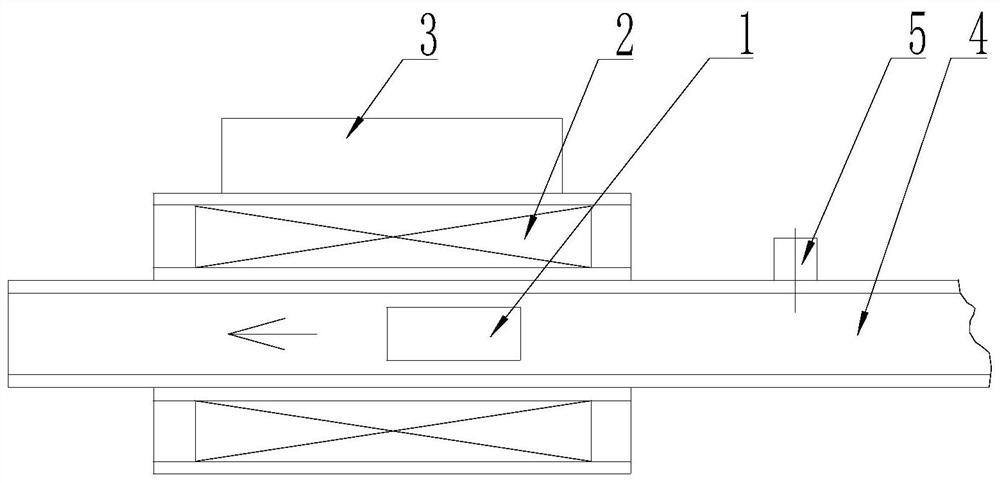

[0023] This embodiment proposes an online demagnetization circuit with fast response to the bearing ring, the structure of which is as follows figure 1 As shown, it includes electronic starting circuit, delay control circuit, voltage-controlled voltage regulator Y and demagnetization coil L. Among them, the electronic start-up circuit includes a primary start-up branch and a secondary start-up branch. A proximity switch K (i.e., a position switch), an input terminal of a photocoupler G, and a resistor R1 are arranged in series on the primary-side start-up branch, wherein the proximity switch It is used to arrange on the side of the feeding channel of the feeding mechanical device, that is, the side of the bearing ring inlet of the demagnetization coil; the output terminal of the photocoupler G, resistor R2, triode T, and triode are arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com