Supercapacitor based on heterojunction polymer gel electrolyte and its preparation method

A polymer gel, supercapacitor technology, applied in the field of energy storage devices, can solve the problems of lack of universality, limited application of supercapacitors, and small results, to suppress the self-discharge process, prolong the self-discharge time, reduce The effect of charge rearrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

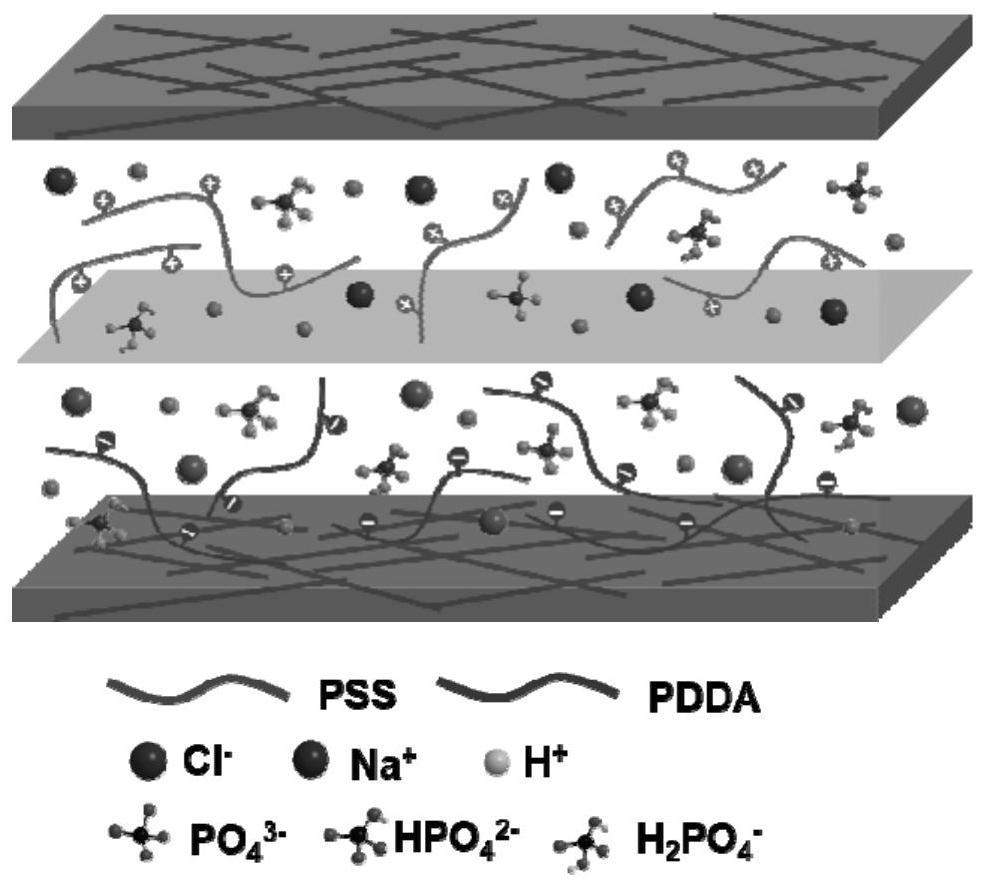

[0033] A supercapacitor based on a heterojunction polymer gel electrolyte, the schematic diagram of the fabricated structure is shown in figure 1 As shown, the specific steps are:

[0034] (1) Dissolve polyvinyl alcohol in deionized water under heating conditions (70°C), the mass ratio of polyvinyl alcohol to water is 1:20, keep stirring for 2 hours, add phosphoric acid with a molar concentration of 0.5mol / L after cooling And stir evenly, then add poly(4-sodium styrene sulfonate), the mass ratio of poly(4-sodium styrene sulfonate) and polyvinyl alcohol / phosphoric acid electrolyte solution is 1:10, after stirring 30min evenly, obtain obtained Described polyvinyl alcohol / phosphoric acid / poly (4-sodium styrene sulfonate) electrolyte solution;

[0035] (2) Dissolve polyvinyl alcohol in deionized water under heating conditions (70°C), the mass ratio of polyvinyl alcohol to water is 1:20, keep stirring for 2 hours, add phosphoric acid with a molar concentration of 0.5mol / L after c...

Embodiment 2

[0045] A supercapacitor based on a heterojunction polymer gel electrolyte and a preparation method thereof, the specific steps are:

[0046] (1) Dissolve polyvinyl alcohol in deionized water under heating conditions (75°C), the mass ratio of polyvinyl alcohol to water is 1:10, keep stirring for 3 hours, add phosphoric acid with a molar concentration of 1mol / L after cooling and Stir evenly, then add poly(4-sodium styrene sulfonate), the mass ratio of poly(4-sodium styrene sulfonate) and polyvinyl alcohol / phosphoric acid electrolyte solution is 1:6, after stirring for 40min evenly, the described Polyvinyl alcohol / phosphoric acid / poly(sodium 4-styrenesulfonate) electrolyte solution;

[0047] (2) Dissolve polyvinyl alcohol in deionized water under heating conditions (75°C), the mass ratio of polyvinyl alcohol to water is 1:10, keep stirring for 3 hours, add phosphoric acid with a molar concentration of 1mol / L after cooling and Stir evenly, then add polydiene dimethyl ammonium chl...

Embodiment 3

[0053] A supercapacitor based on a heterojunction polymer gel electrolyte and a preparation method thereof, the specific steps are:

[0054] (1) Dissolve polyvinyl alcohol in deionized water under heating conditions (80°C), the mass ratio of polyvinyl alcohol to water is 1:6, keep stirring for 4 hours, add phosphoric acid with a molar concentration of 1.5mol / L after cooling And stir evenly, then add poly(4-sodium styrene sulfonate), the mass ratio of poly(4-sodium styrene sulfonate) and polyvinyl alcohol / phosphoric acid electrolyte solution is 1:5, after stirring 60min evenly, obtain obtained Described polyvinyl alcohol / phosphoric acid / poly (4-sodium styrene sulfonate) electrolyte solution;

[0055] (2) Dissolve polyvinyl alcohol in deionized water under heating conditions (80°C), the mass ratio of polyvinyl alcohol to water is 1:6, keep stirring for 4 hours, add phosphoric acid with a molar concentration of 1.5mol / L after cooling And stir evenly, then add polydiene dimethyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com