A sunflower seed harvester with inserting plate and directly taking off food

A harvester and sunflower-eating technology, used in harvesters, agricultural machinery and implements, agriculture, etc., can solve the problems of high labor intensity, grain loss, and inability to directly harvest sunflower-eating, so as to avoid the loss of sunflower seeds and realize mechanization. and automated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

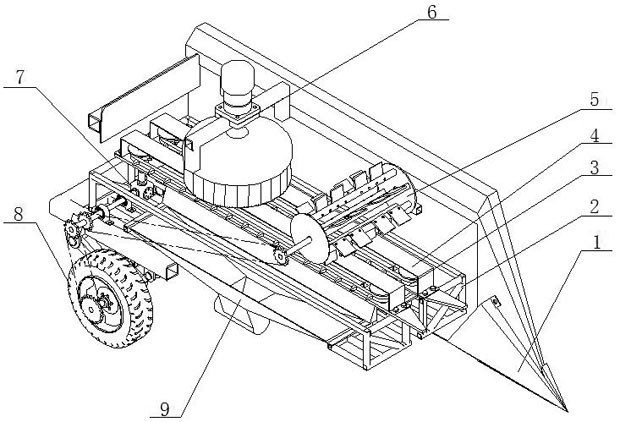

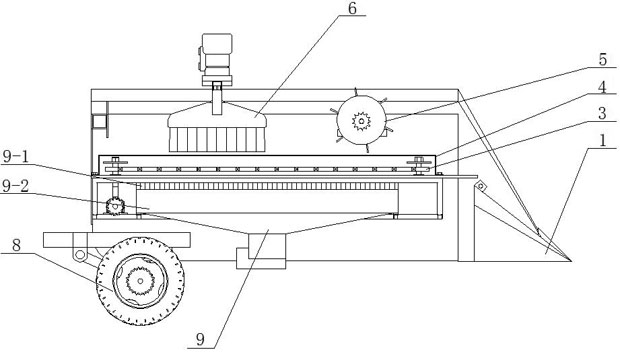

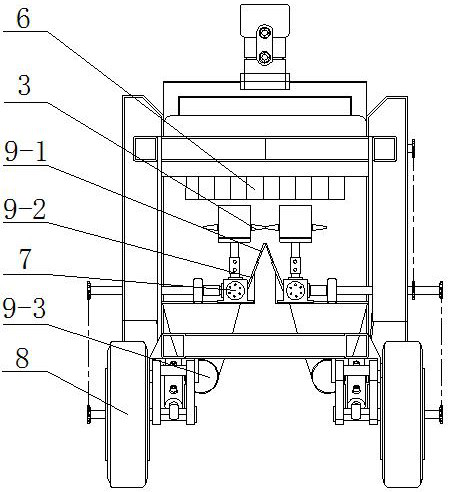

[0020] The inserting disc of present embodiment takes off directly and eats sunflower seed harvester such as figure 1 Shown, comprise grain dividing device 1, frame 2, driving lever chain 3, sunflower plate pallet 4, dial device 5, threshing device 6, transmission case 7, ground wheel 8 and collection device 9, in frame 2 The outer side is wrapped with a cover, which is used to connect with the grain dividing device 1, and at the same time prevent the seeds from splashing. The grain dividing device 1 is connected at the front end, and the rear of the grain dividing device 1 is equipped with a lever chain 3 and a sunflower tray 4 fixed on the frame. 2, a dial device 5 is set above the front end of the frame 2, a threshing device 6 is fixed above the rear of the frame 2, a transmission box 7 is fixed on the bottom of the rear of the frame 2, and the ground wheel 8 transmits power through a chain and a drive shaft. Transfer to the transmission box 7, the lever chain 3 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com