Five-row longitudinal ear picking type ear and stem harvesting corn harvester header

A technology for corn harvesters and headers, which is applied to headers, harvesters, cutters, etc., can solve the problems of easy push rods, heavy forage pollution, easy blockage of headers and other problems, and achieve the effect of improving harvesting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

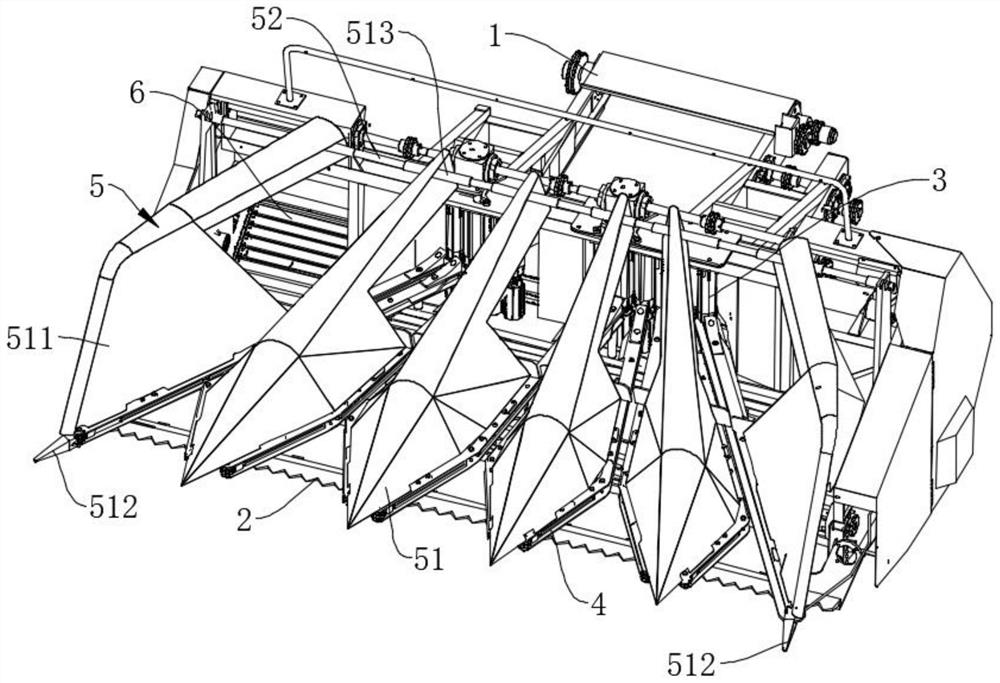

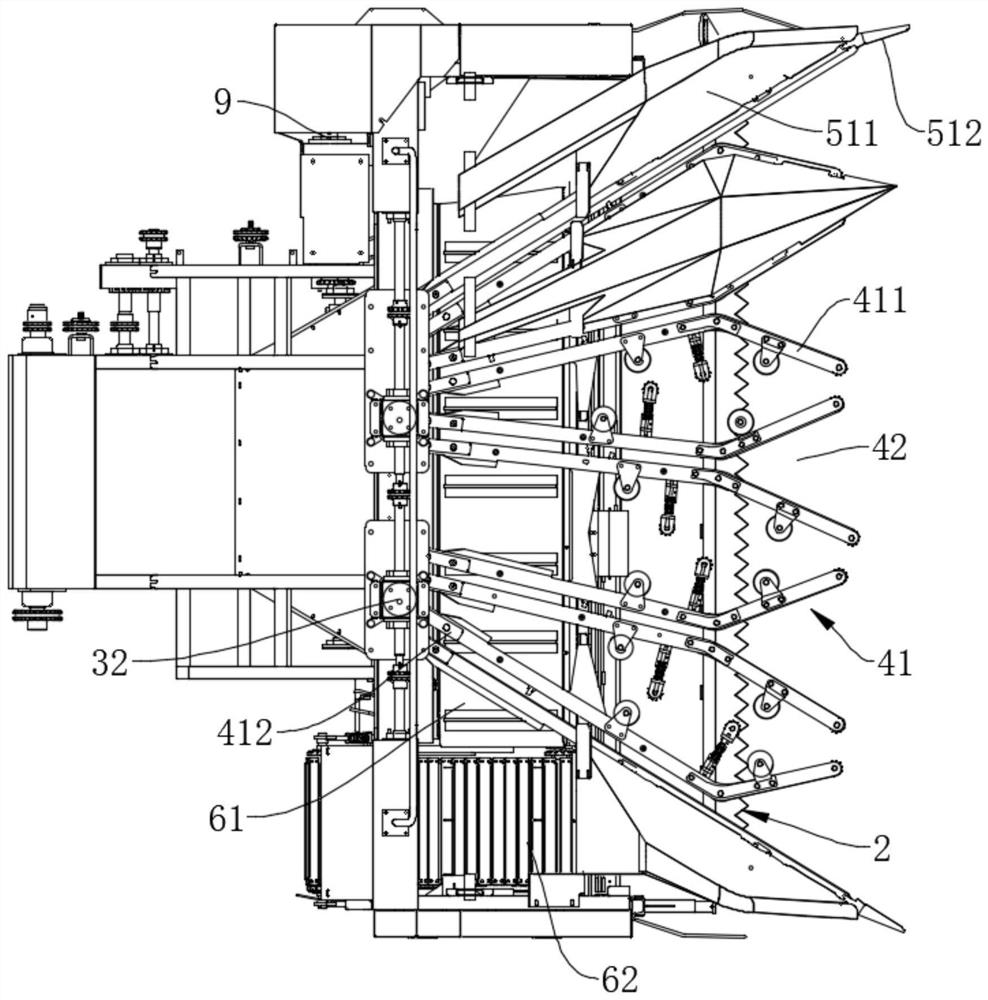

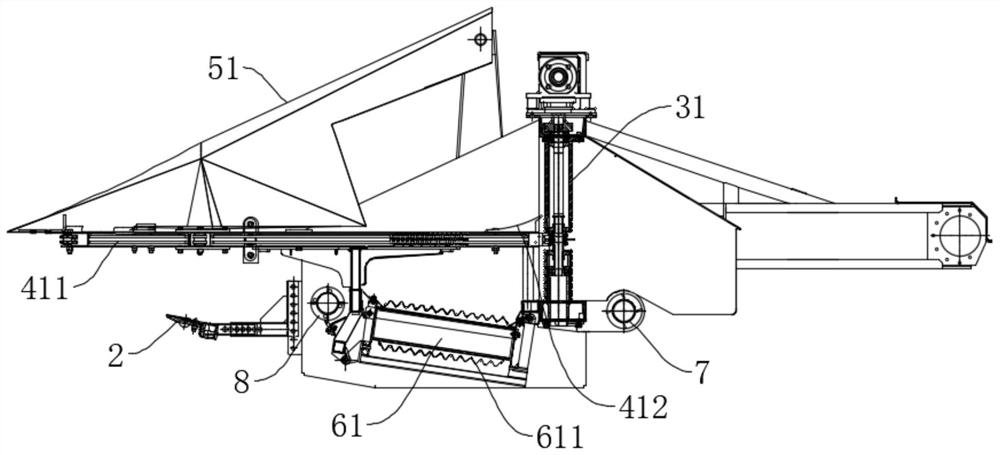

[0030] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7As shown, this embodiment provides a five-row vertically placed corn harvester with ear and stem combined harvesting, including a header body 1, and a cutter mechanism 2 for cutting straw roots is installed on the header body 1 , the fringe-picking mechanism 3 for pulling stems and fringing, the grain-holding mechanism 4 for transporting plants to the fringe-plucking mechanism 3, the grain dividing device 5 for introducing plants into the grain-holding mechanism 4, and the ear for conveying fruit ears Conveying me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com