Pipe bending and die clamping device

A technology of clamping and bending pipes, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems affecting the structural strength of pipe fittings, wrinkles, large stress concentration of pipe fittings, etc., to ensure the appearance and structural strength, to avoid wrinkles fold effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

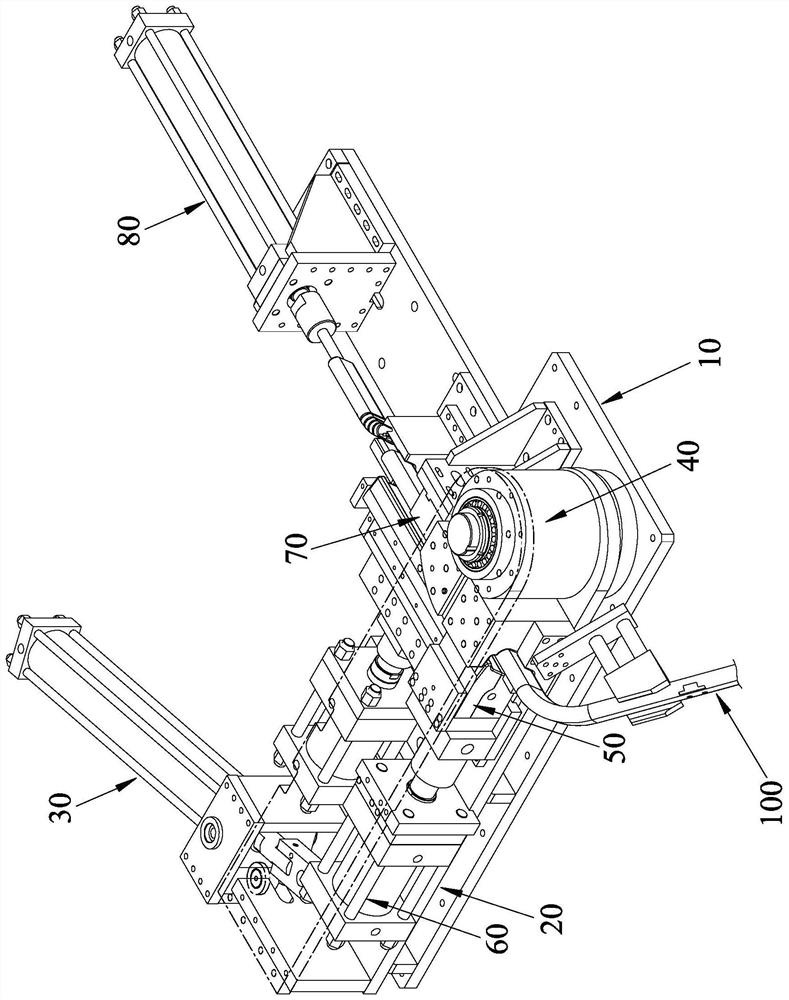

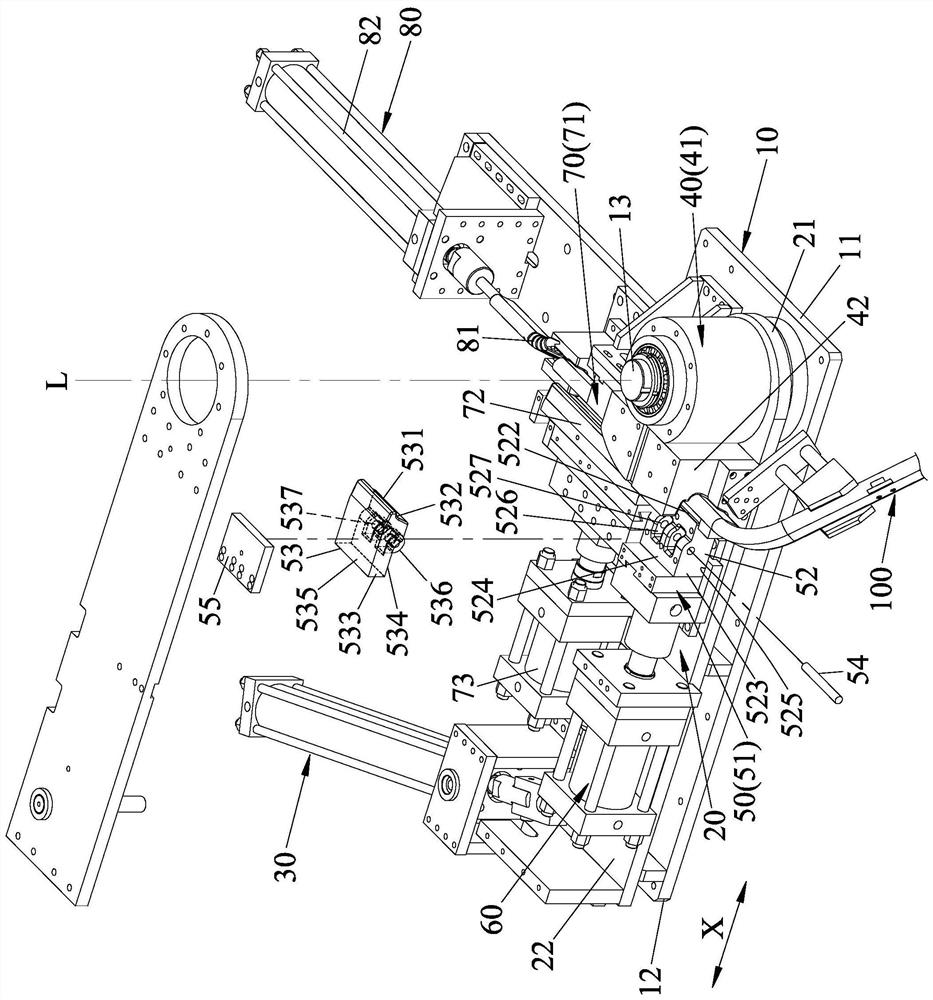

[0020] refer to figure 2 and image 3 , an embodiment of the bending pipe clamping device of the present invention, comprising a base 10, a bending pipe arm 20, a bending pipe driving member 30, a main mold unit 40, a clamping mold unit 50, and a clamping mold driving member 60 , a guide mold unit 70 and a core mold unit 80 .

[0021] The base 10 is plate-shaped and includes a first end 11, a second end 12 opposite to the first end 11 along a transverse axis X, and a The shaft 13 extends transversely to the axis L of the X axis.

[0022] The elbow arm 20 includes a pivot end 21 pivoted on the shaft 13 , and a driving end 22 opposite to the pivot 21 .

[0023] The pipe bending driver 30 is installed on the base 10 and can drive the driving end 22 of the pipe bending arm 20 to rotate around the axis L relative to the base 10 . The bending pipe driving member...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com