Curved screen film pasting device

A technology of film sticking device and curved screen, which is applied to household components, home appliances, other home appliances, etc., can solve the problems such as the inability to quickly change the distance between the air outlet and the curved screen, the inability of the curved screen to be in complete contact with the film, and the inability to quickly change the film, etc. , to achieve good practicality and creativity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

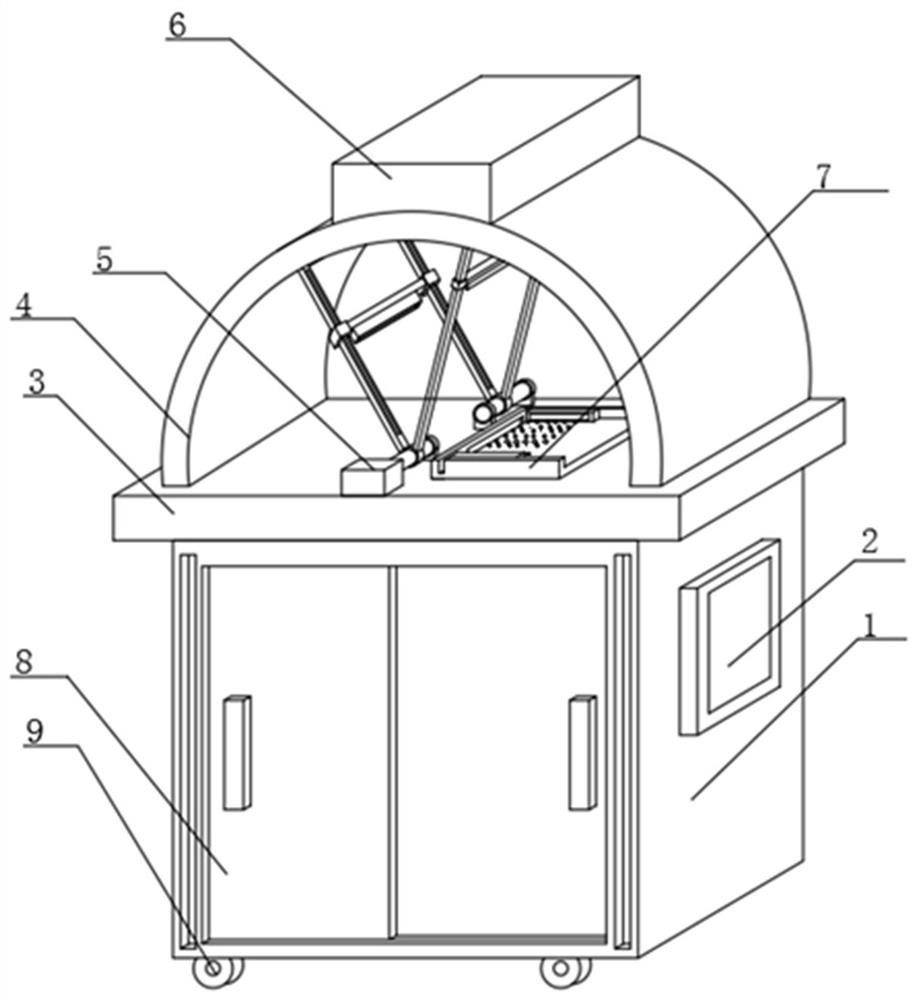

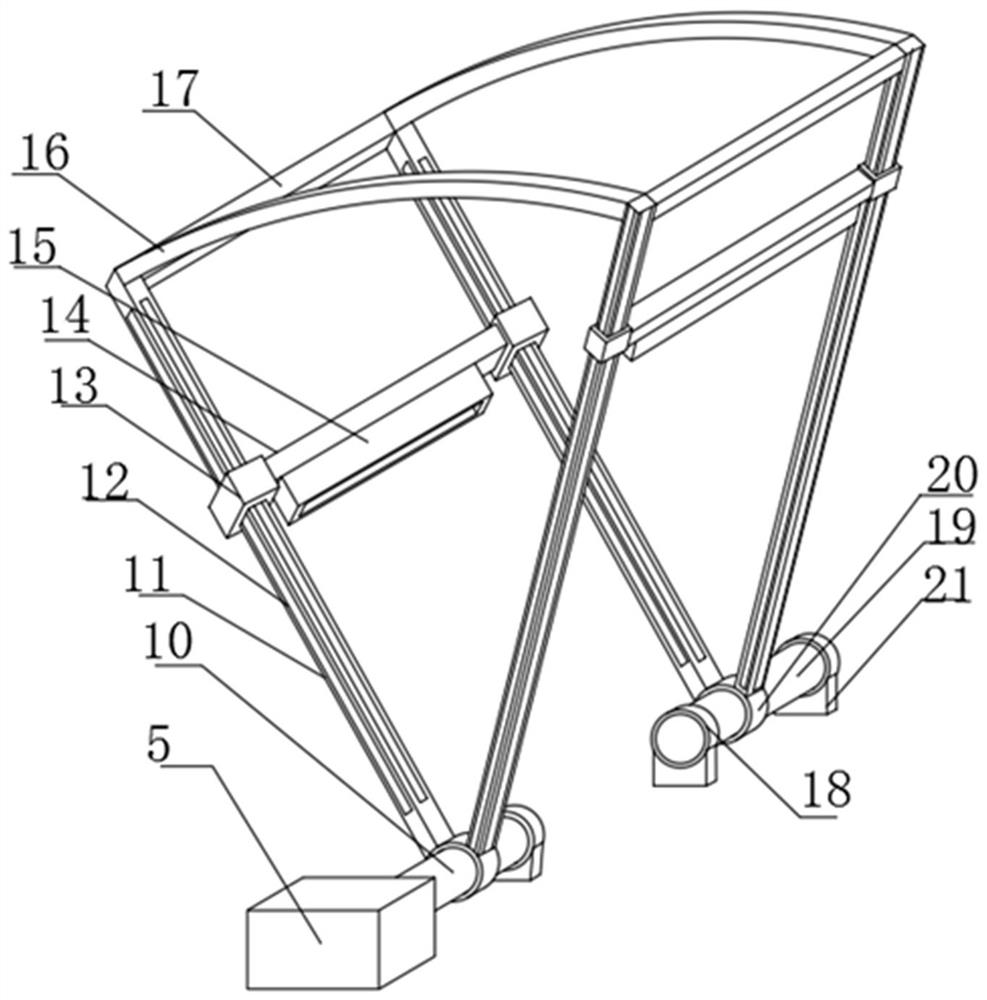

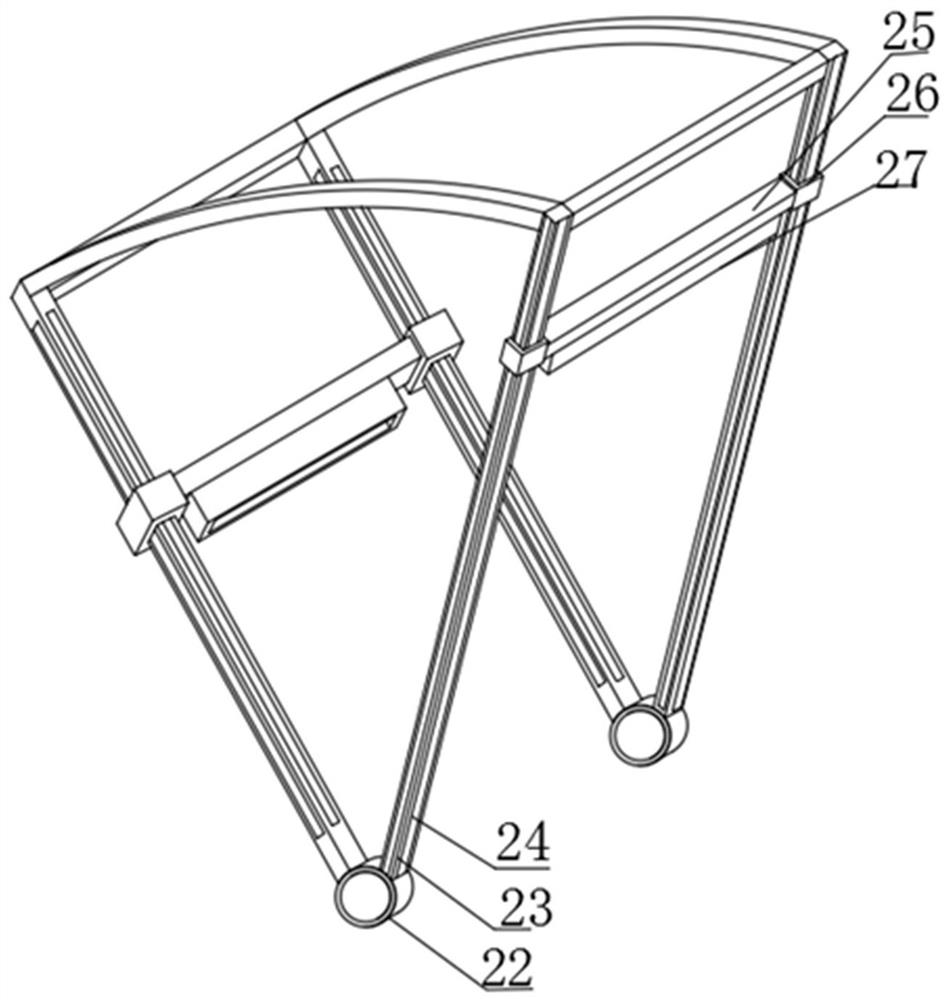

[0031] Such as Figure 1-9 As shown, a curved screen film sticking device includes a body (1), a control panel (2) is fixedly installed on the right side of the body (1), and an operation console (3) is fixedly installed on the upper surface of the body (1). The upper surface of (3) is fixed with an arc frame (4), the upper surface of the console (3) and the bottom of the arc frame (4) is fixed with a motor (5), and the upper surface of the arc frame (4) The air pump (6) is fixedly installed on the surface, the output end of the motor (5) is connected to the drive rod (10), and the outer surface of the drive rod (10) is fixedly sleeved with a connecting collar (22), and the connecting collar (22) No. 1 connecting rail (11) and No. 2 connecting rail (23) are fixedly installed on the outer surface;

[0032] The angle formed by the No. 1 connecting rail (11) and the No. 2 connecting rail (23) is 30 degrees, and the outer surface of the transmission rod (10) is provided with a No...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap