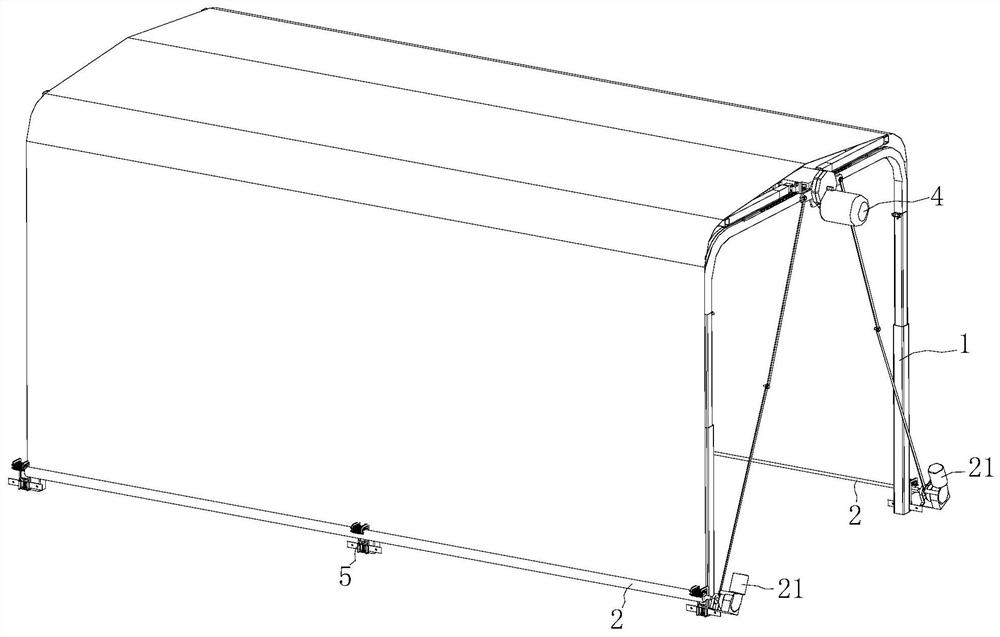

Tarpaulin covering and collecting device

A tarpaulin, cover and retract technology, applied in the direction of load coverage, transportation and packaging, vehicles for freight, etc., can solve the problems of increased labor, tarpaulin damage, tarpaulin shaft deformation, etc., to achieve the effect of increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

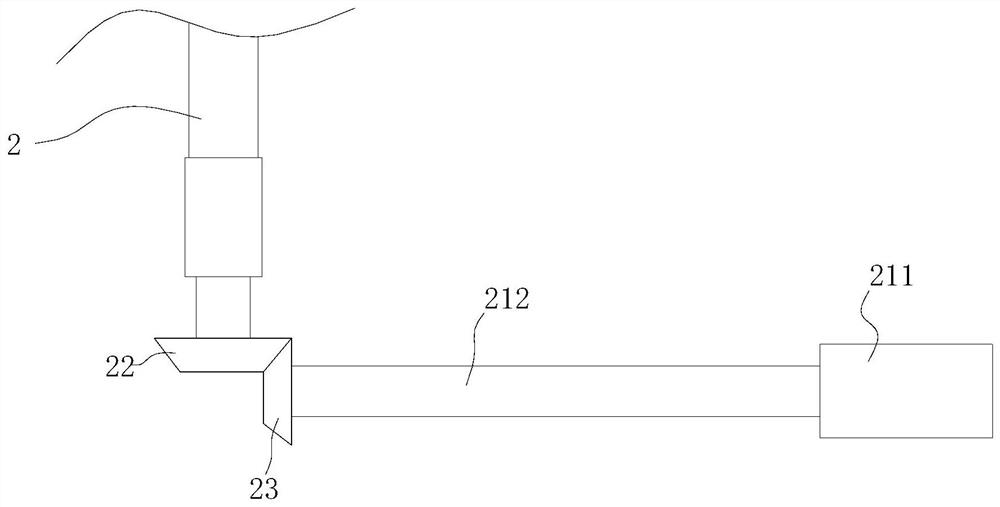

[0076] Embodiment 1: In this embodiment, the guide pulley 56 is arranged on the first tensioning member 511. When the tarpaulin reel 2 is rolled into the fixing groove 53, the first tensioning member 511 is in direct contact with the tarpaulin reel 2, so the guide pulley 56 is arranged on the first tensioning member 511, which relieves the tension of the first tensioning member 511 on the tarpaulin reel 2 and the tarpaulin. Pulling force to prevent the tarpaulin from breaking.

Embodiment 2

[0077] Embodiment 2: In this embodiment, the guide pulley 56 is arranged on the second tensioning member 512, and the tarpaulin reel 2 is rolled into the fixing groove along the opening of the second tensioning member 512 53, so the guide pulley 56 is arranged on the opening edge of the second tension member 512, so that the tarpaulin reel 2 is involved in the fixing groove 53 along the guide arc surface of the guide pulley 56 , play a guiding role for the tarpaulin reel 2, so that the movement of the tarpaulin reel 2 is smoother and more convenient.

Embodiment 3

[0078] Embodiment 3: as a kind of preferred embodiment of the present application, such as Figure 6 As shown, the first tensioning member 511 and the second tensioning member 512 are both provided with the guide pulley 56, so that the guide pulley 56 can not only guide the movement of the tarpaulin reel 2, but also Relieves tension on the tarpaulin.

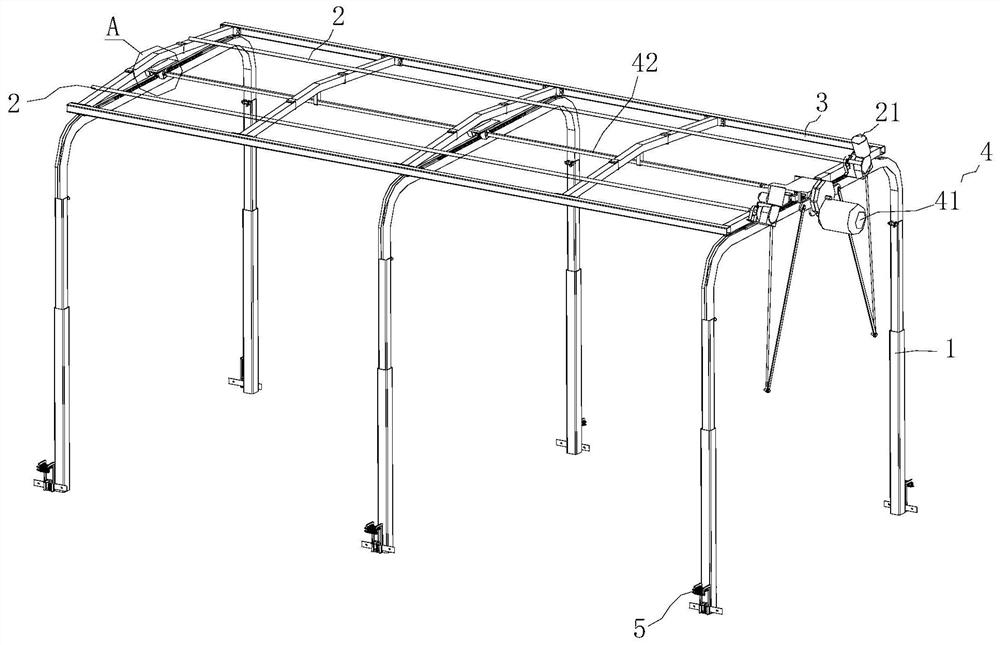

[0079] As a preferred embodiment of this application, such as Figure 7 As shown, the bracket 1 has a support portion 11 extending vertically, and a support portion 12 fixedly connected to the top of the support portion 11 and arranged horizontally, the support portion 12 and the support portion 11 The junction is an arc transition.

[0080] The covering member 3 and the tarpaulin reel 2 are more gentle when moving between the supporting portion 11 and the supporting portion 12, preventing the covering member 3 from violently colliding with the bracket 1, causing the The lifetime of the bracket 1 or the cover 3 is reduced.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com