Biogas biological desulfurization device and desulfurization method

A biological desulfurization and biogas technology, applied in gas fuel, petroleum industry, fuel, etc., can solve the problems of affecting desulfurization efficiency, complicated operation, clogging of packing layer, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

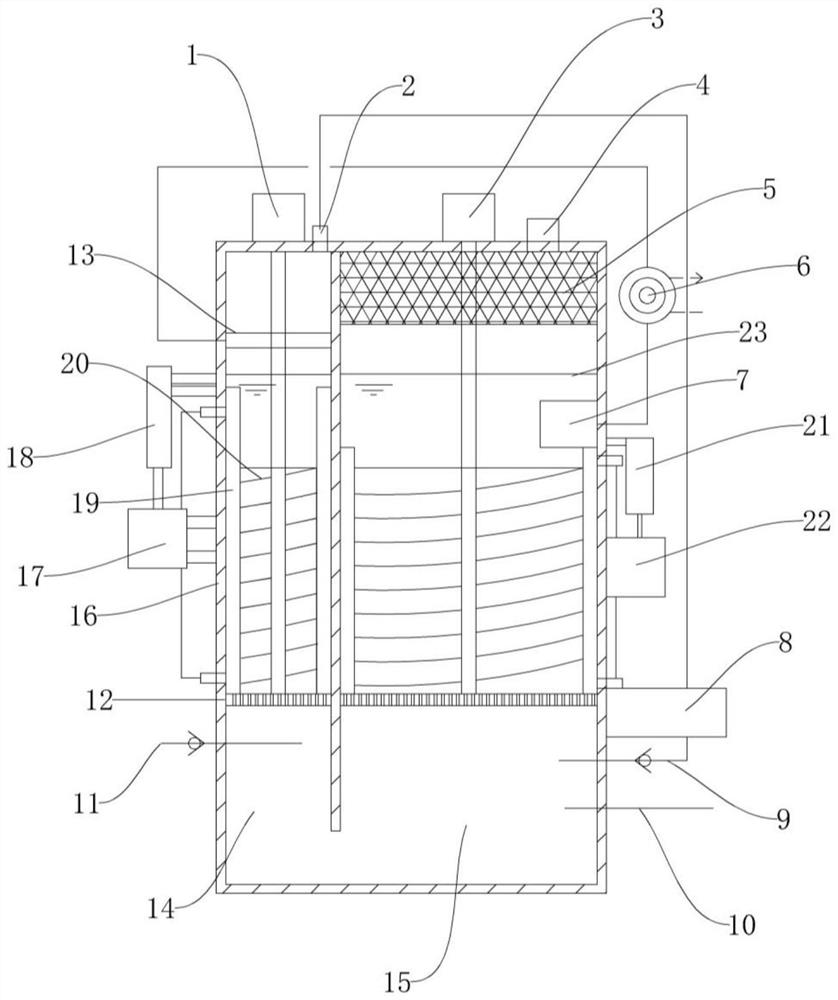

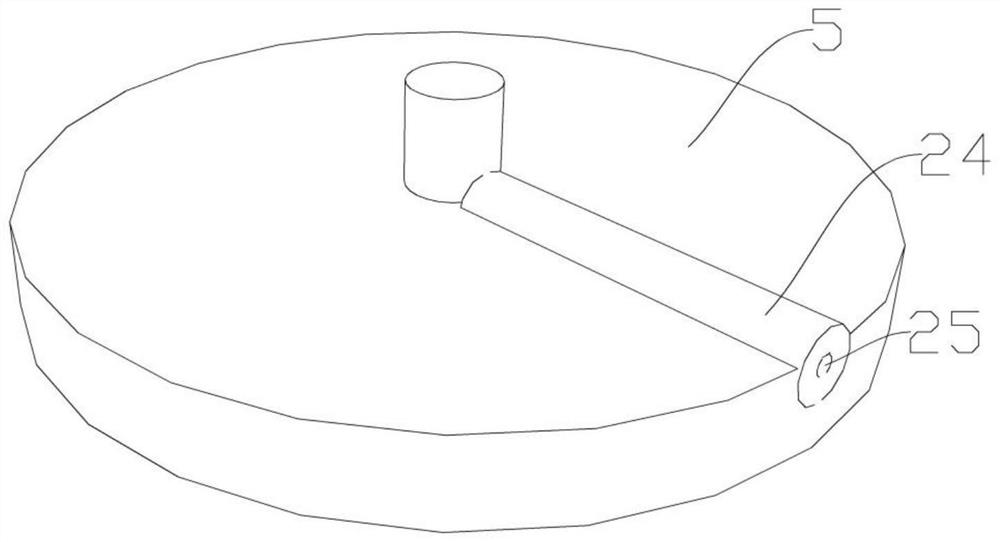

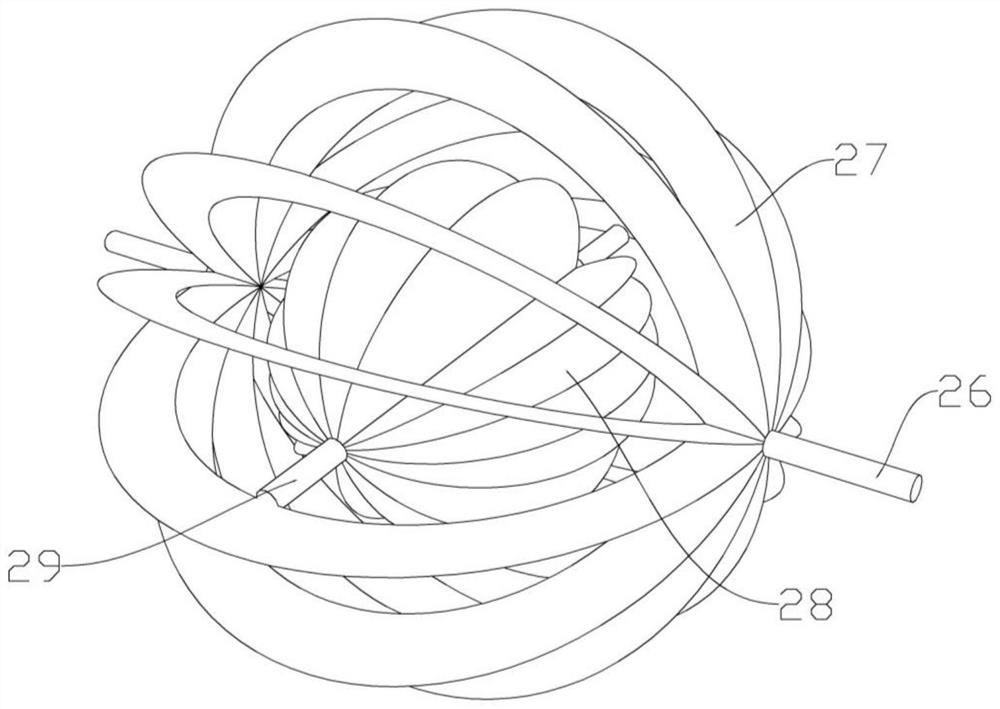

[0033] Such as Figure 1-5 As shown, a biogas desulfurization device includes a desulfurization tower main body 16, a first reaction chamber 14 and a second reaction chamber 15 are arranged inside the desulfurization tower main body 16, and the first reaction chamber 14 and the second reaction chamber 15 are Separated by a partition, there is a gap between the bottom of the partition and the main body 16 of the desulfurization tower, the first reaction chamber 14 and the second reaction chamber 15 are in communication, when the water pump 7 moves the second reaction chamber When the desulfurization liquid 23 in the upper part of the chamber 15 is pumped to the spray device 13, the flow rate of the desulfurization liquid 23 in the first reaction chamber 14 can be effectively increased. After the flow rate is increased, the generated elemental su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com