Ultra-fine desulfurization tower for efficiently removing organic sulfur and desulfurization method

A desulfurization tower and desulfurization liquid technology, which is applied in the petroleum industry, gas fuel, air quality improvement, etc., can solve the problems of cumbersome operation, packing layer blockage, and long time consumption, so as to avoid excessive reaction, complete desulfurization reaction, and gentle contact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

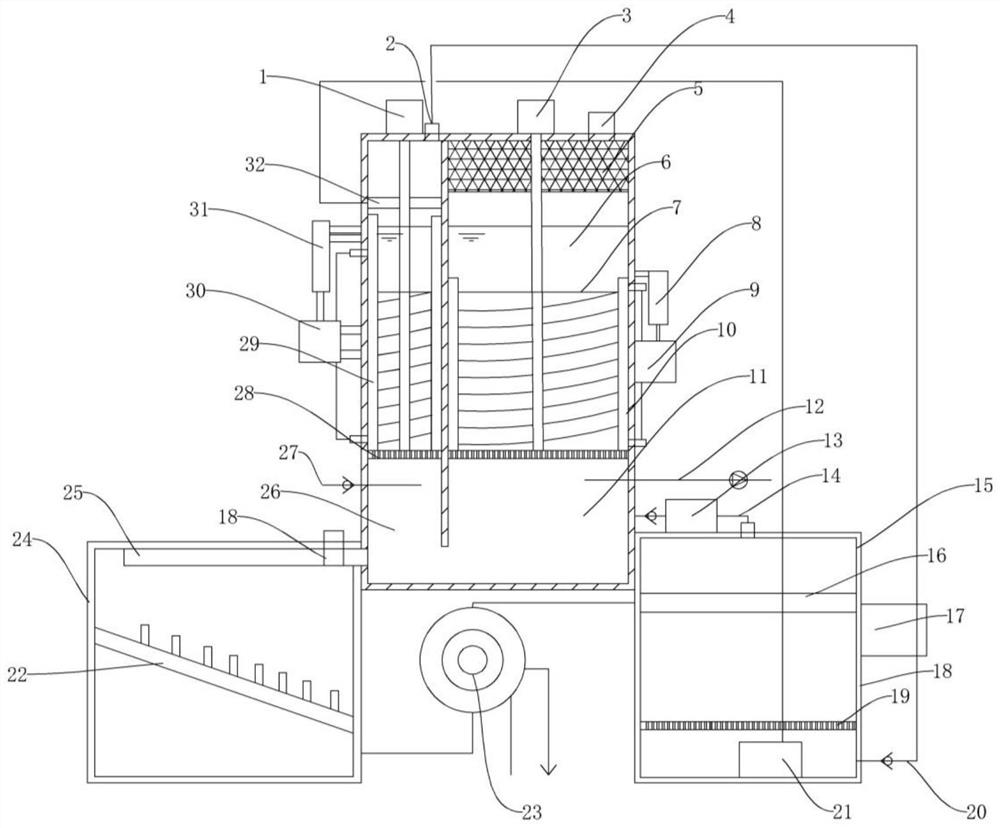

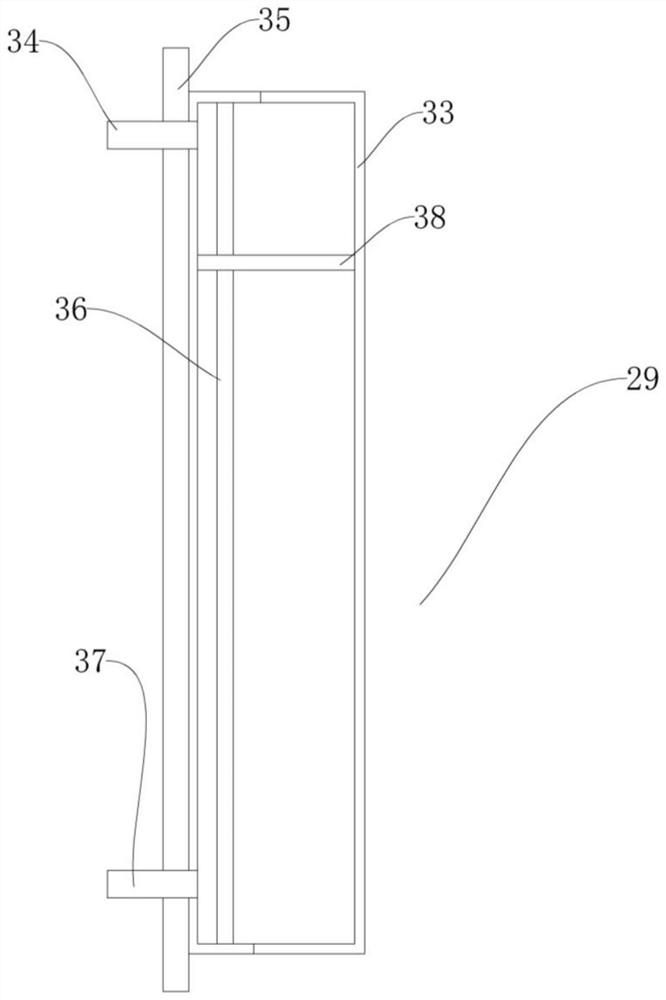

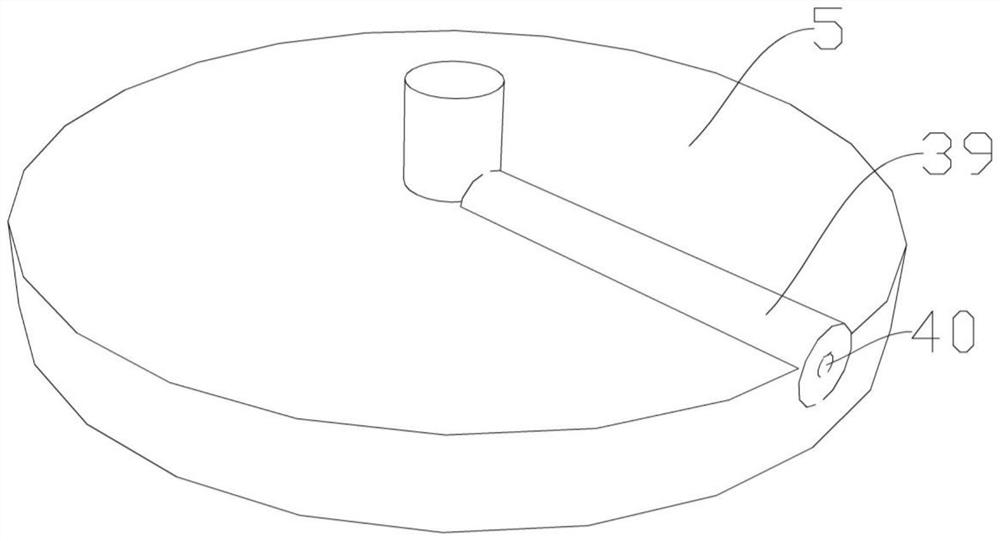

[0037] Such as Figure 1-6 As shown, a biogas desulfurization device includes a desulfurization tower main body, a first reaction chamber 26 and a second reaction chamber 11 are arranged inside the desulfurization tower main body, and a gap between the first reaction chamber 26 and the second reaction chamber 11 Separated by a partition, there is a gap between the bottom of the partition and the main body of the desulfurization tower, the first reaction chamber 26 is in communication with the second reaction chamber 11, and the cross-sectional area of the first reaction chamber 26 is the same as The cross-sectional area ratio of the second reaction chamber 11 is 1:2, the initial biogas rises more concentrated after entering the first reaction chamber 26, and the contact between the generated bubbles and the first biological filler device is m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com