Hydraulic system for controlling controllable-pitch propeller

A hydraulic system and hydraulic pump technology, applied in the field of controllable pitch propellers, can solve the problems of increasing investment and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the purpose, technical solution and advantages of the present disclosure clearer, the implementation manners of the present disclosure will be further described in detail below in conjunction with the accompanying drawings.

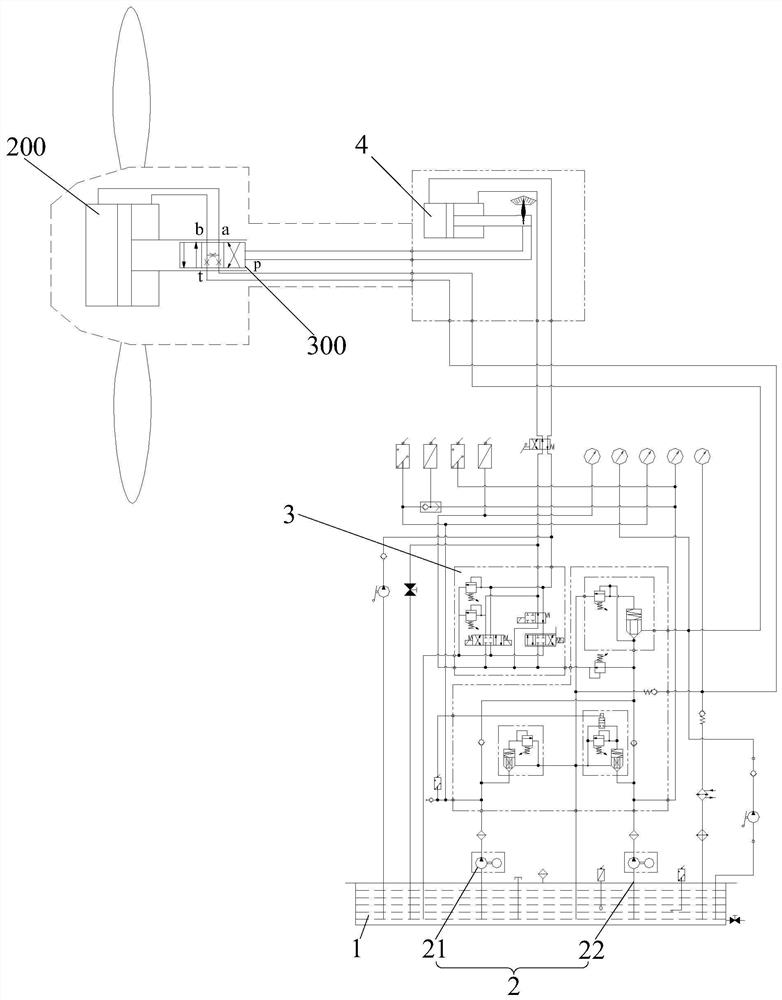

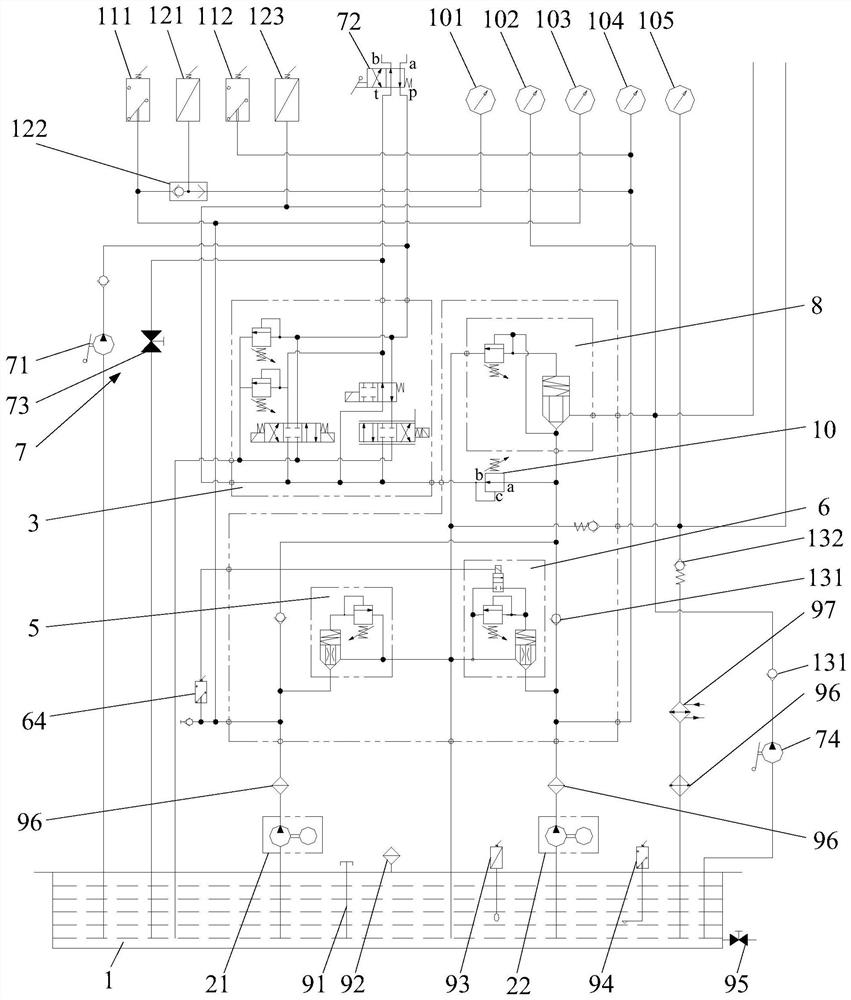

[0032] figure 1 It is a hydraulic diagram of a hydraulic system used for controllable pitch propeller control provided by an embodiment of the present disclosure. In order to introduce the hydraulic system more clearly, the following combines figure 1 , first explain the structure and working principle of the controllable pitch propeller.

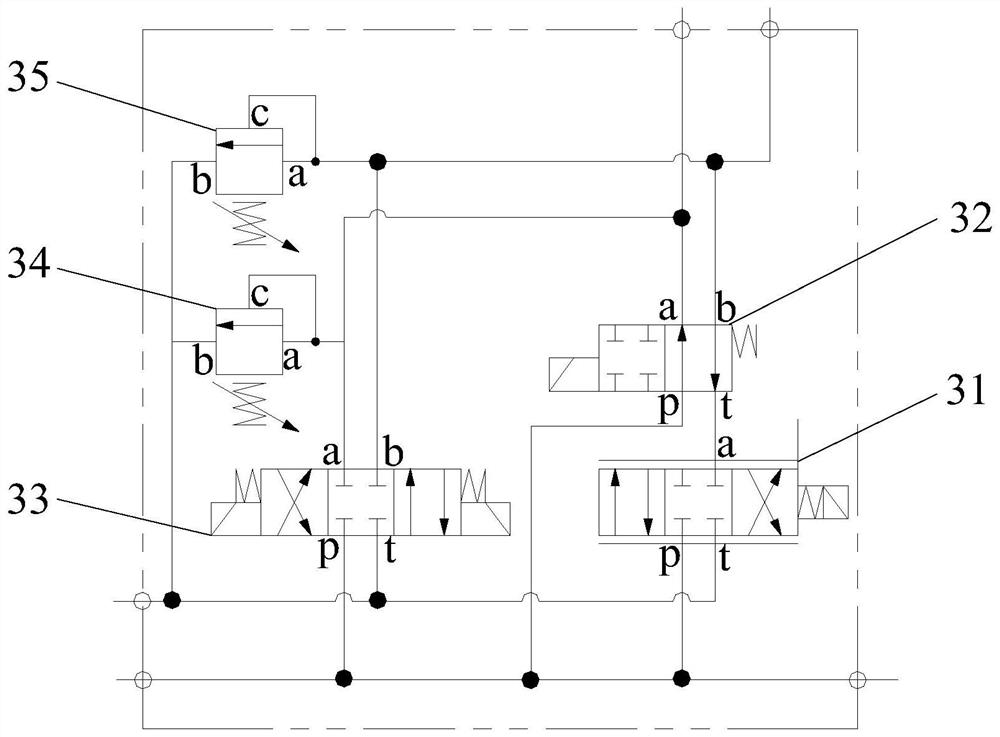

[0033] In this embodiment, the controllable pitch propeller includes a hub oil cylinder 200 and a second three-position four-way reversing valve 300 . Wherein, the piston rod of the servo cylinder 4 is connected with the spool of the second three-position four-way reversing valve 300, and the valve sleeve of the second three-position four-way reversing valve 300 is connected with the piston rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com