Hydraulic control system of cone crushing main machine and control method thereof

A hydraulic control system and cone crushing technology, which is applied to the components of fluid pressure actuation system, mechanical equipment, fluid pressure actuation device, etc. Unreasonable design and other problems, to achieve the effect of novel overall structure, convenient adjustment, and ensure normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below through specific embodiments.

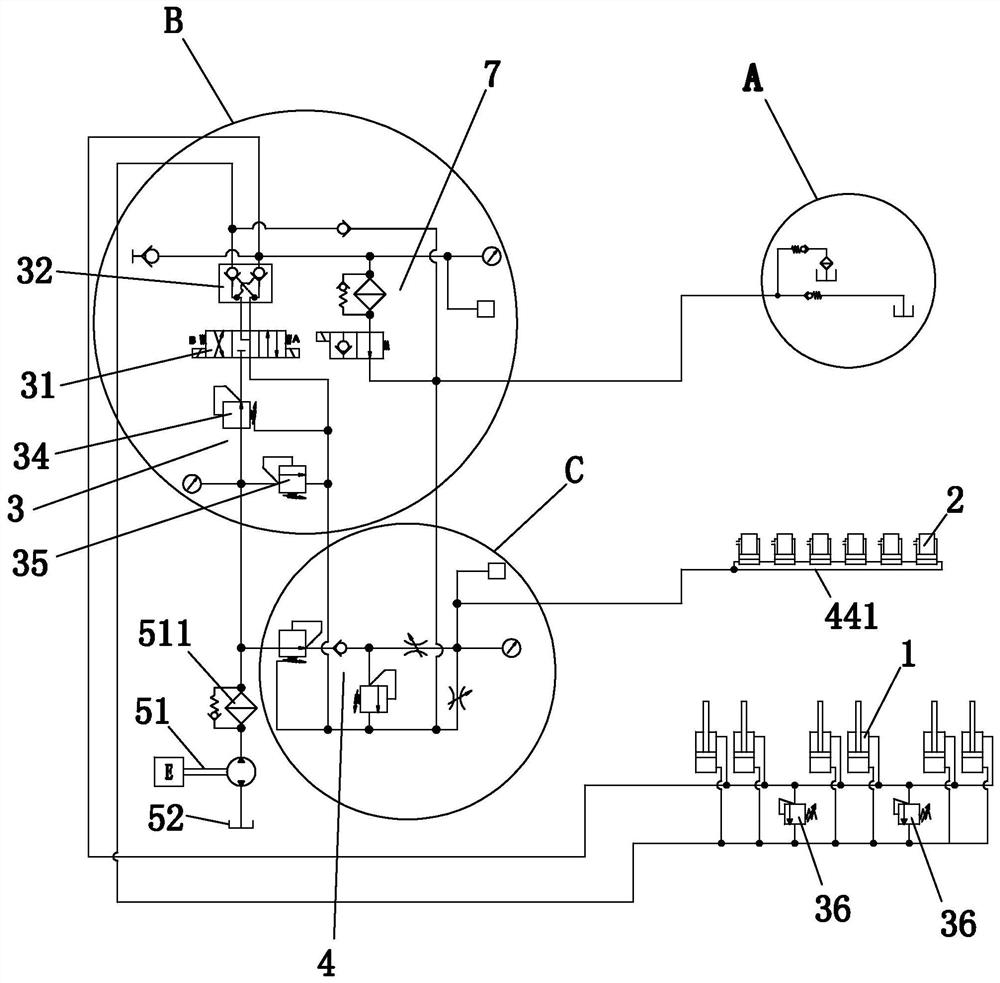

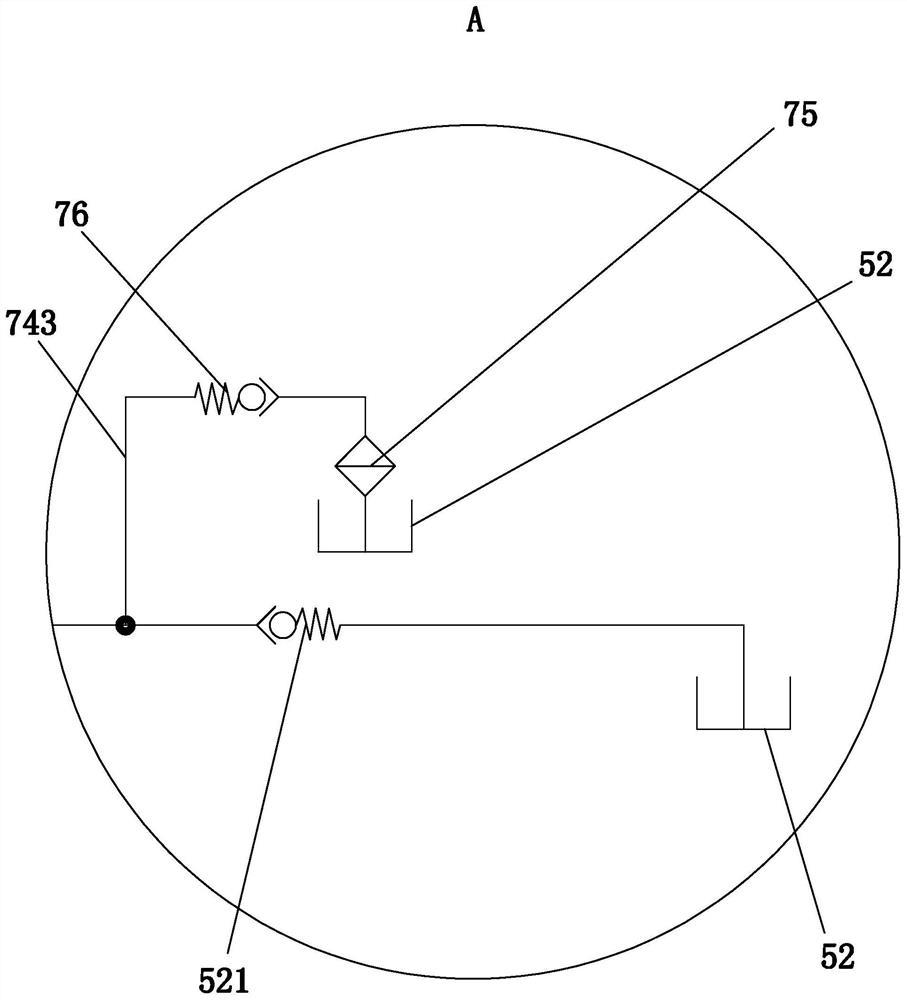

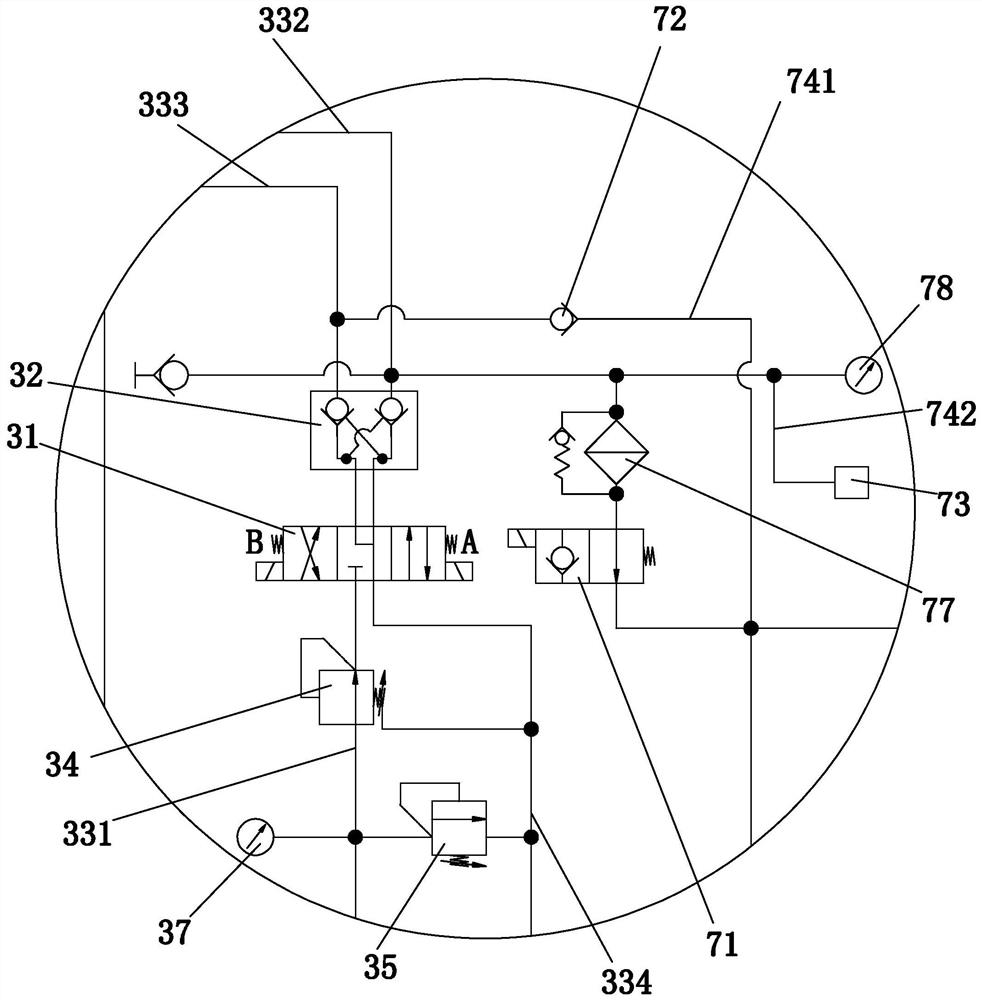

[0035] like Figure 1 to Figure 5 As shown, the hydraulic control system of a cone crushing main engine according to the present invention includes a plurality of adjustment hydraulic cylinders 1, a plurality of stubby jack hydraulic cylinders 2, a discharge opening adjustment circuit 3, an upper frame holding circuit 4, a power The element 51 and the hydraulic oil tank 52, a plurality of the adjustment hydraulic cylinders 1 are arranged in parallel, the power element 51 is used to convert the hydraulic oil in the hydraulic oil tank 52 into pressure oil and supply it to the discharge port adjustment circuit 3 and the upper frame holding circuit 4, the discharge port regulation circuit 3 is used to control the action of the adjustment hydraulic cylinder 1, and the adjustment hydraulic cylinder 1 is used to drive the upper frame 61 to move up and down to adjust the discharge mouth size,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com