Turbine structure using electromagnetic bearing

An electromagnetic bearing and turbine technology, applied in the direction of magnetic bearings, bearings, bearing components, etc., can solve the problems of limited application and low temperature tolerance, and achieve the effect of solving high operating temperature, improving working temperature and simple structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

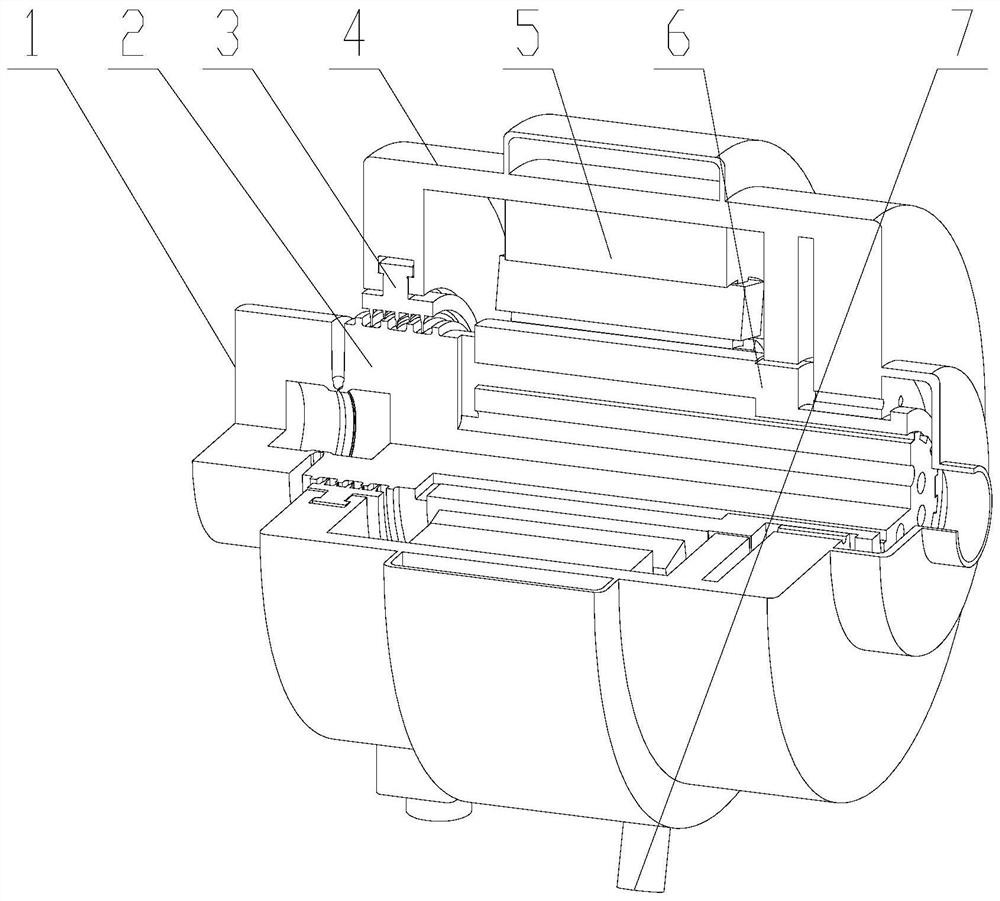

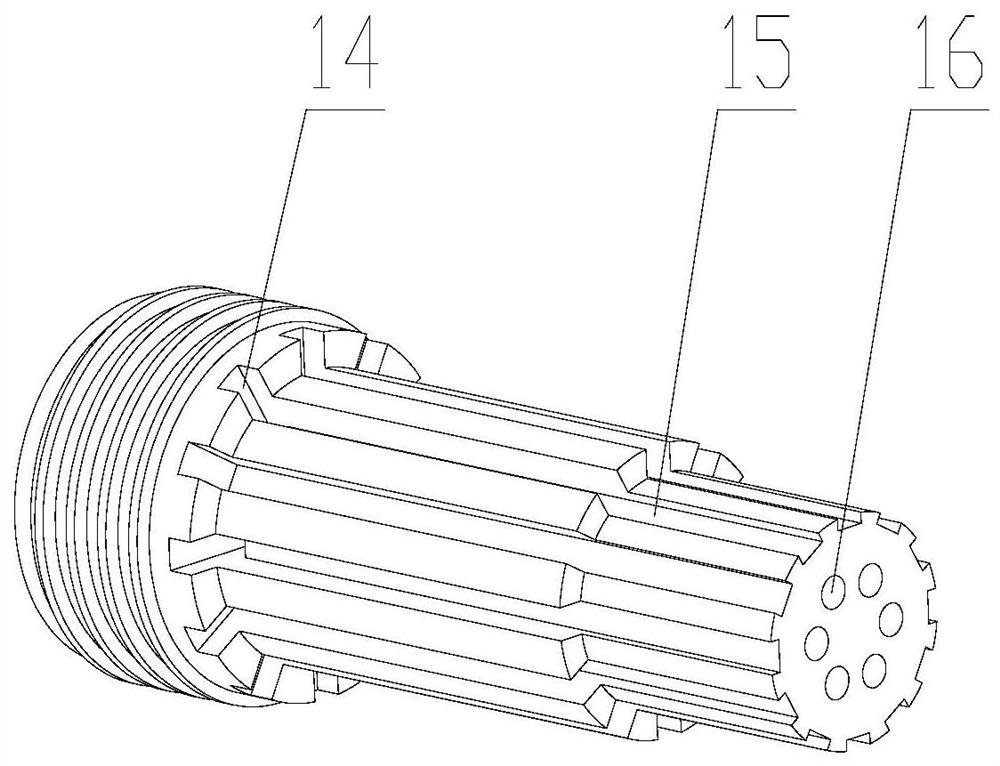

[0033] Embodiment one is basically as Figure 1 to Figure 3As shown: this embodiment provides a turbine structure using electromagnetic bearings, which can make high-temperature turbine equipment use electromagnetic bearing technology better, and can effectively ensure the safe and stable operation of electromagnetic bearings for high-temperature turbine equipment; the turbine The structure includes the turbine rotor I1, the turbine rotor II2 and the bearing box 4 located outside the turbine rotor II2, as well as the bearing rotor 6 and the bearing stator 5. The bearing box 4 is one of the stationary parts of the turbine structure, and the turbine rotor I1 It is fixedly connected with the turbine rotor II2; the bearing rotor 6 is set on the turbine rotor II2, and the inner circle of the bearing rotor 6 is in interference fit with the outer circle of the turbine rotor II2, and the bearing stator 5 is fixed on the inner chamber of the bearing box 4 The inner circle corresponds t...

Embodiment 2

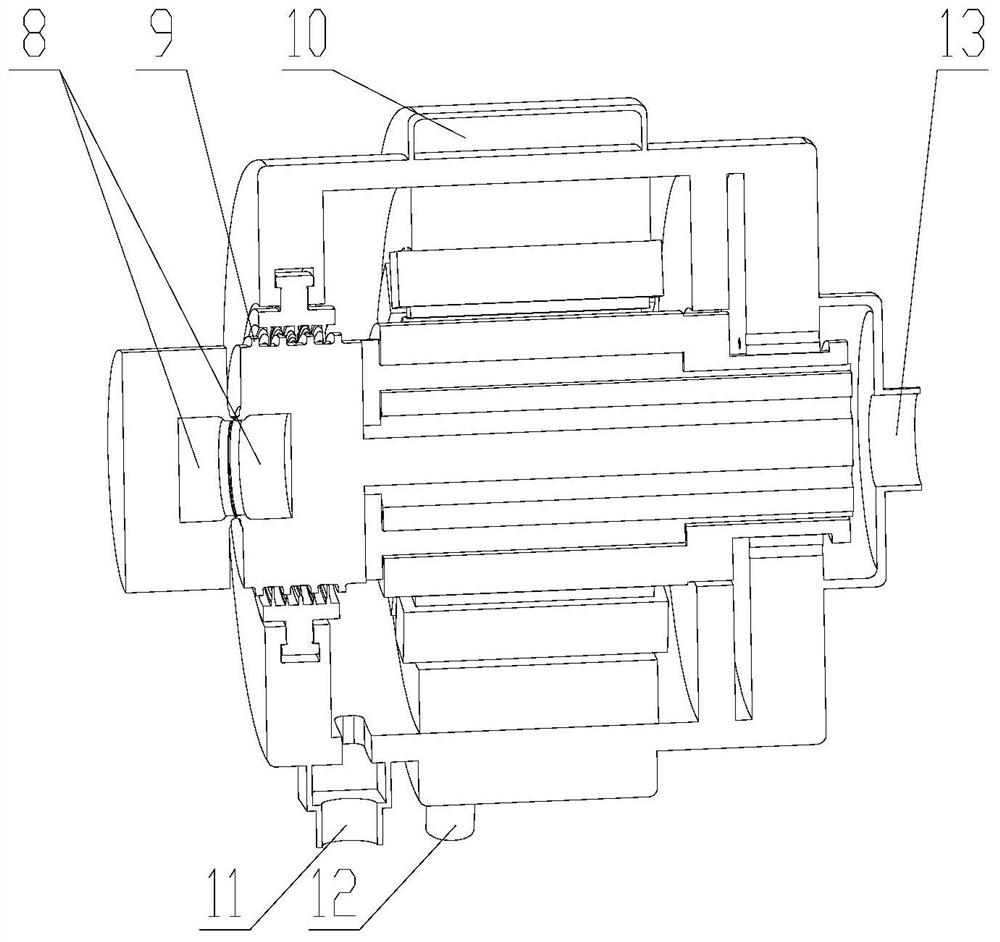

[0047] Embodiment two is basically the same as embodiment one, and its difference is: as figure 1 and figure 2 As shown, this embodiment provides a turbine structure using electromagnetic bearings. On the basis of Embodiment 1, the cooling structure provided by this embodiment also includes a water-cooled structure for the magnetic bearing stator 5; specifically, the water-cooled structure for the magnetic bearing stator 5 It includes an annular cooling chamber 10 arranged on the housing of the bearing housing 4, and the annular cooling chamber 10 is equipped with a cooling water inlet 12 and a cooling water outlet 7, so that cooling water can enter the annular cooling chamber 10 from the cooling water inlet 12, and After heat exchange, the bearing box 4 flows out through the cooling water outlet 7 to cool the bearing and the bearing stator 5; with the above-mentioned structure, the bearing box 4 is provided with an annular cooling chamber 10, which can fully absorb the heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com