High-efficiency rzeppa constant velocity universal joint

A constant velocity universal joint and ball cage type technology, which is applied in the direction of elastic couplings, mechanical equipment, couplings, etc., can solve the problem of low heat generation and high efficiency of fixed end ball cage type universal joints, spherical friction and wear, Abnormal sound NVH and other problems, to achieve the effect of improving NVH performance, reducing axial force, and reducing the maximum axial clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

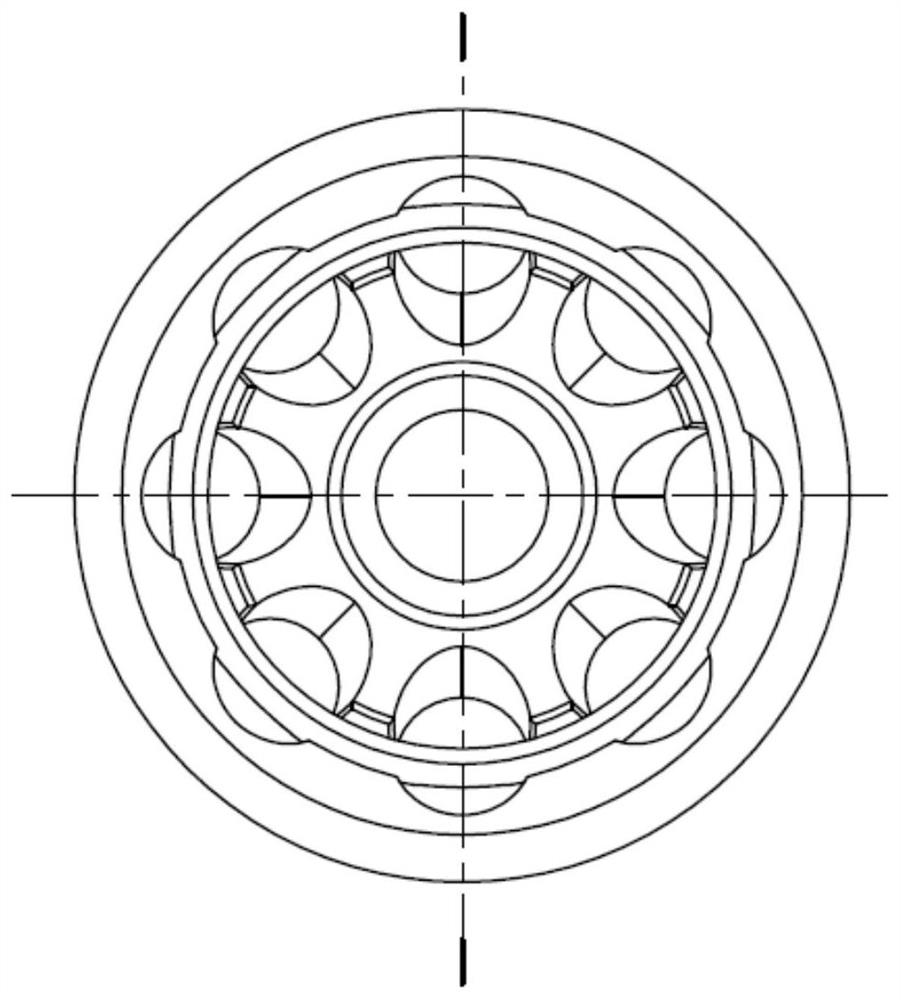

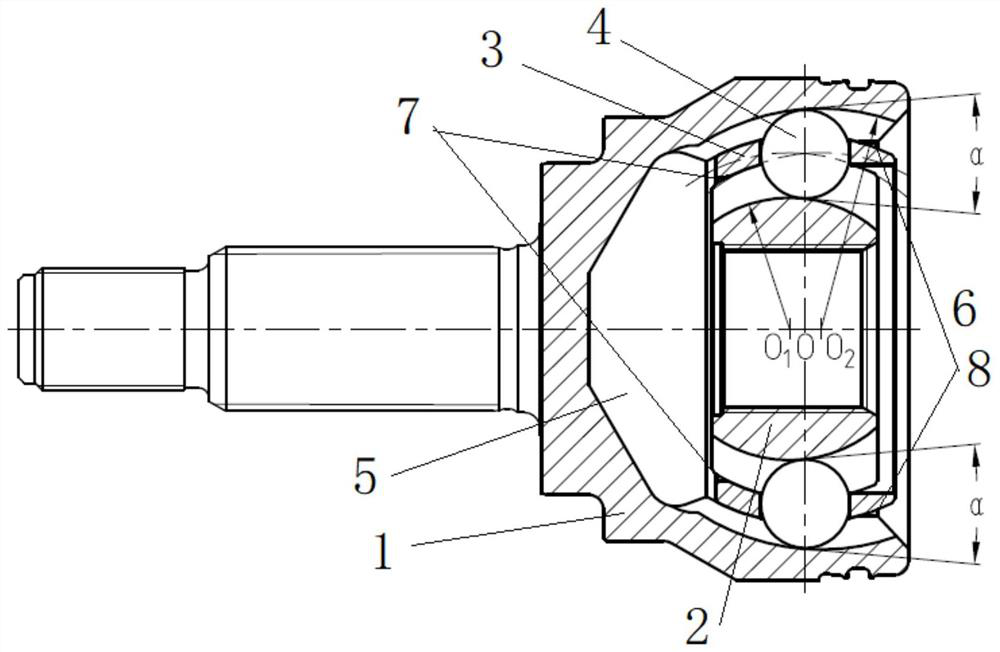

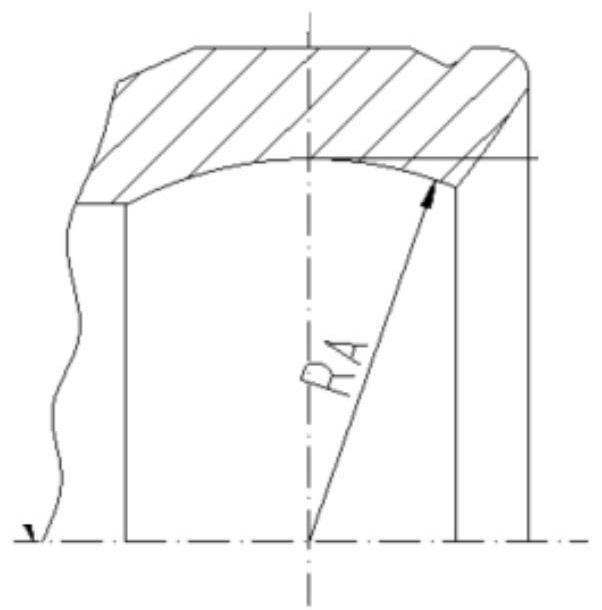

[0029] Embodiment: As shown in the accompanying drawings, this high-efficiency cage type constant velocity universal joint mainly includes a bell shell 1, a star sleeve 2, a cage 3, steel balls 4, an inner side 5, and an opening side 6 , A ballway 9, B ballway 10, the inner spherical surface of the bell-shaped shell 1 is formed with a plurality of ballways extending in the axial direction, and has an opening side 6 and the inner side 5 separated in the axial direction, and the outer spherical surface of the star sleeve 2 is formed with A plurality of ballways paired with the ballways of the bell-shaped shell 1, a plurality of steel balls 4 are sandwiched between the alleys of the bell-shaped shell 1 and the ballways of the star-shaped sleeve 2 and transmit torque, and the number of steel balls 4 is preferably 8, also Can be 6, 9, 10, 12 etc. The steel ball 4 is held by the cage 3. The cage 3 has an outer spherical surface and an inner spherical surface matched with the inner s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com