Smelting furnace aluminum outlet casting nozzle and manufacturing method thereof

A manufacturing method and melting furnace technology, which are applied to furnaces, furnace components, lighting and heating equipment, etc., can solve the problems of fast heat transfer of cast iron, short service life, and high outer wall temperature, and achieve reduced use costs, long service life, and outer wall. low temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0039] The following is an embodiment of an aluminum casting nozzle for a smelting furnace.

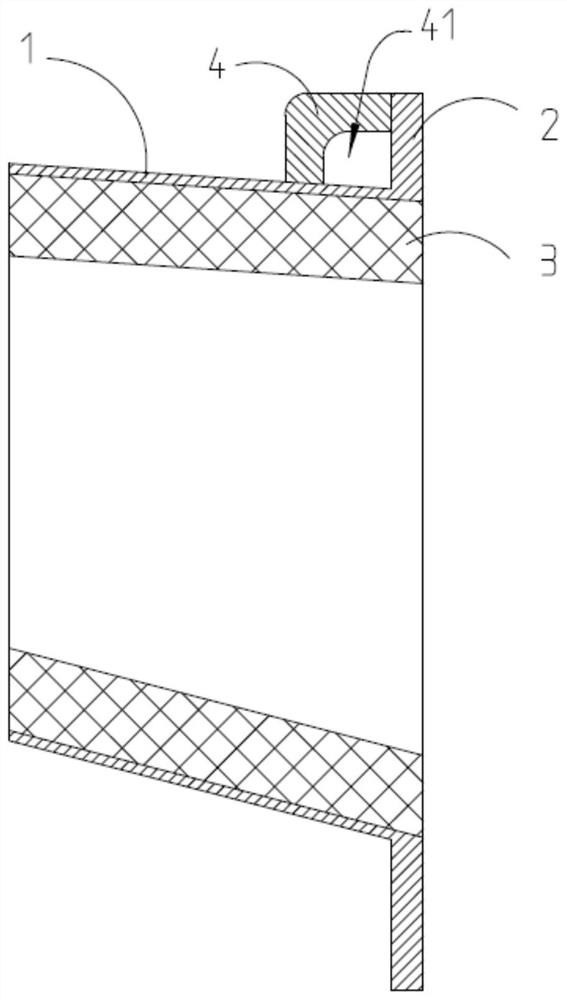

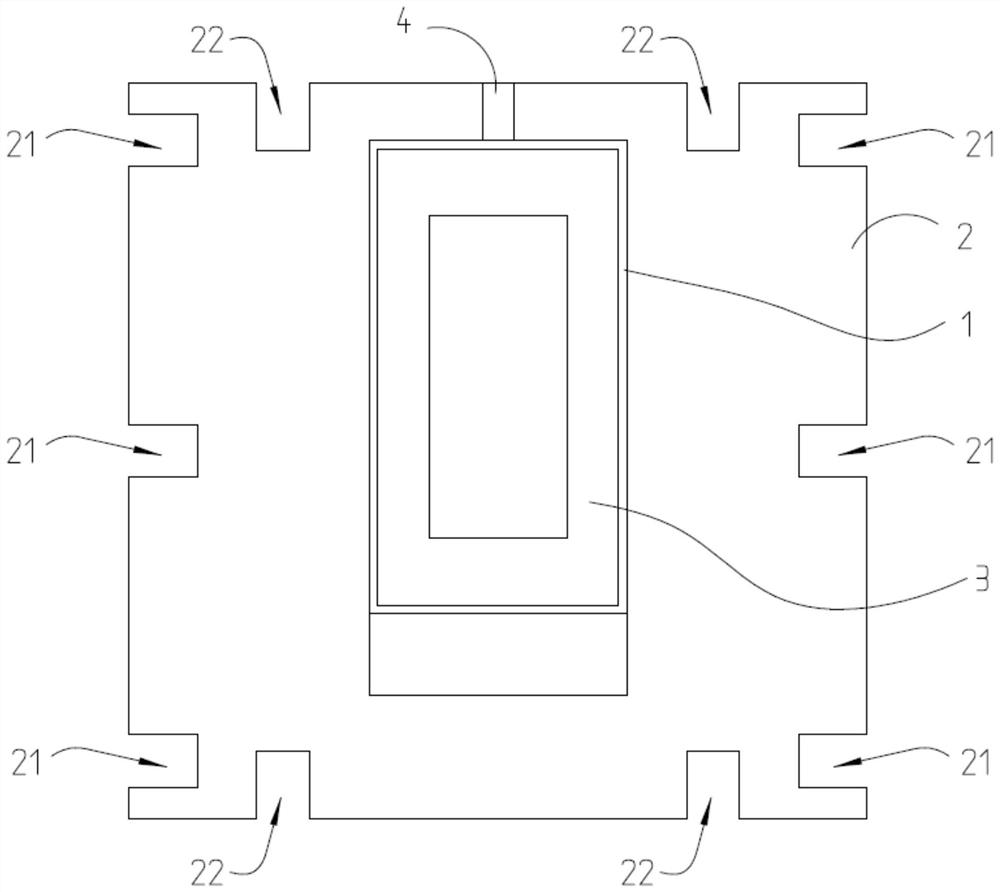

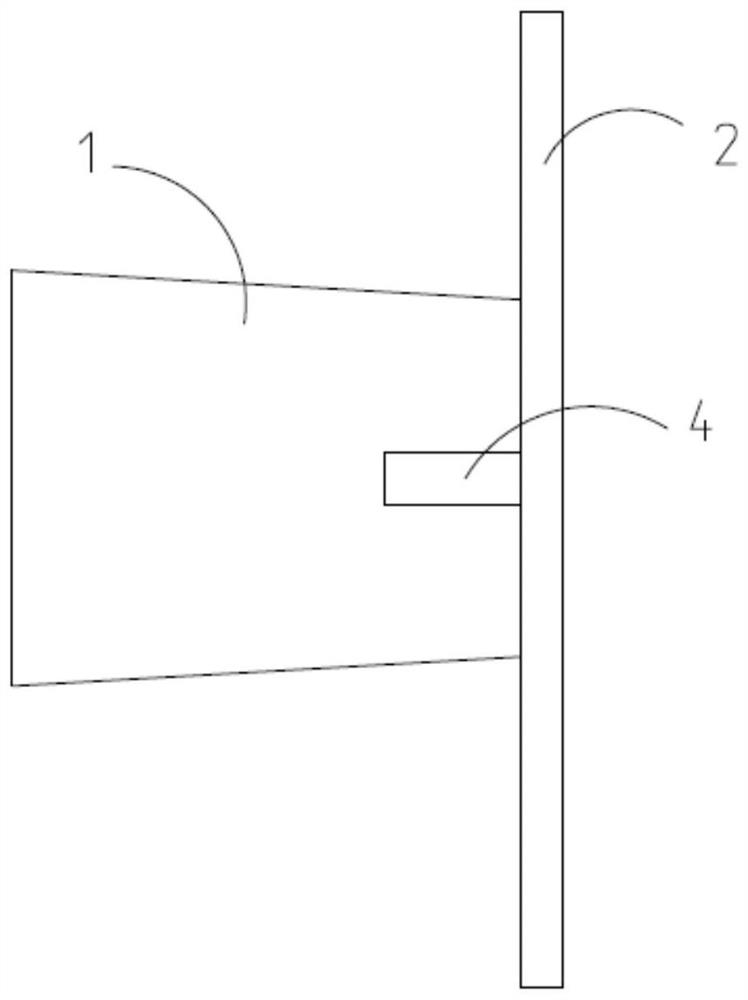

[0040] Please attach Figure 1-3 , an aluminum casting nozzle for a smelting furnace, comprising: an outer covering tube 1 of a tubular structure, a plate-shaped mounting plate 2 extending from one end of the outer covering tube 1, and the aluminum casting nozzle for a melting furnace also includes a tubular structure The pouring pipe 3 is attached to the inside of the covering pipe 1 and completely covers the inner wall of the covering pipe 1 .

[0041] In this embodiment, the aluminum casting nozzle of the smelting furnace adopts a split structure, which solves technical problems by using the inventive principle of splitting. The wall thickness of the pouring pipe 3 is reduced, the structure facilitates molding, and avoids pouring defects caused by excessiv...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap