Non-contact pantograph-catenary contact force measuring method and device

A non-contact, measurement method, applied in the direction of measuring the force of change in optical properties of materials when they are stressed, can solve the problems of incomplete reflection of elastic force, disadvantageous cost savings, etc., and achieve efficient extraction of light strip displacement. Accuracy, high pressure accuracy, the effect of reducing equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

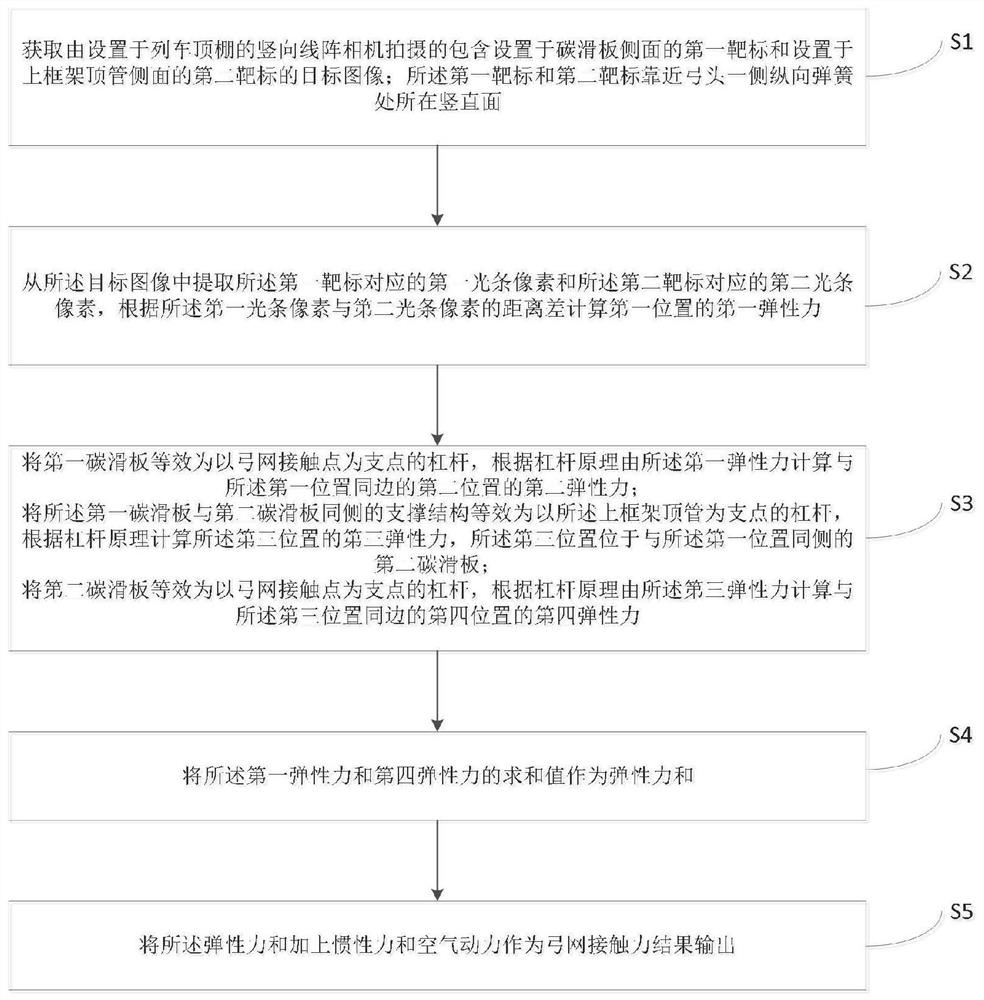

[0050] This embodiment provides a non-contact pantograph-catenary contact force measurement method, such as figure 1 mentioned, including:

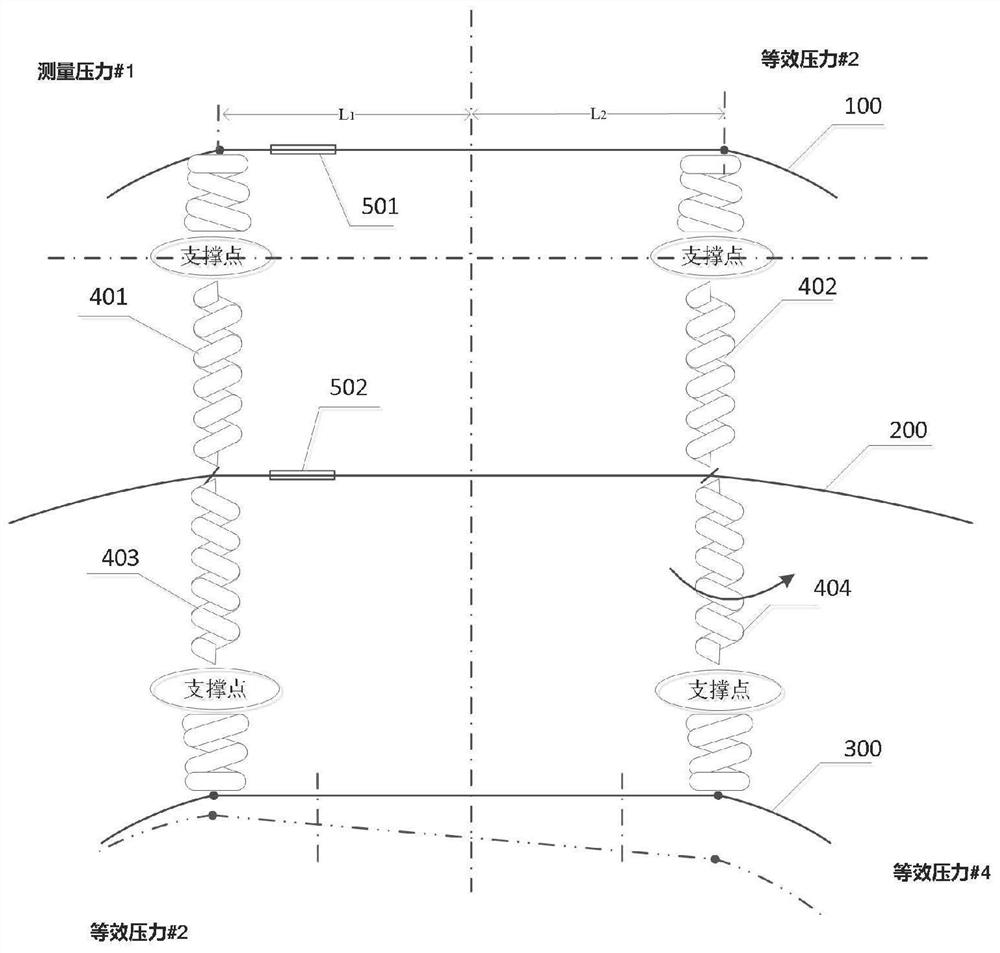

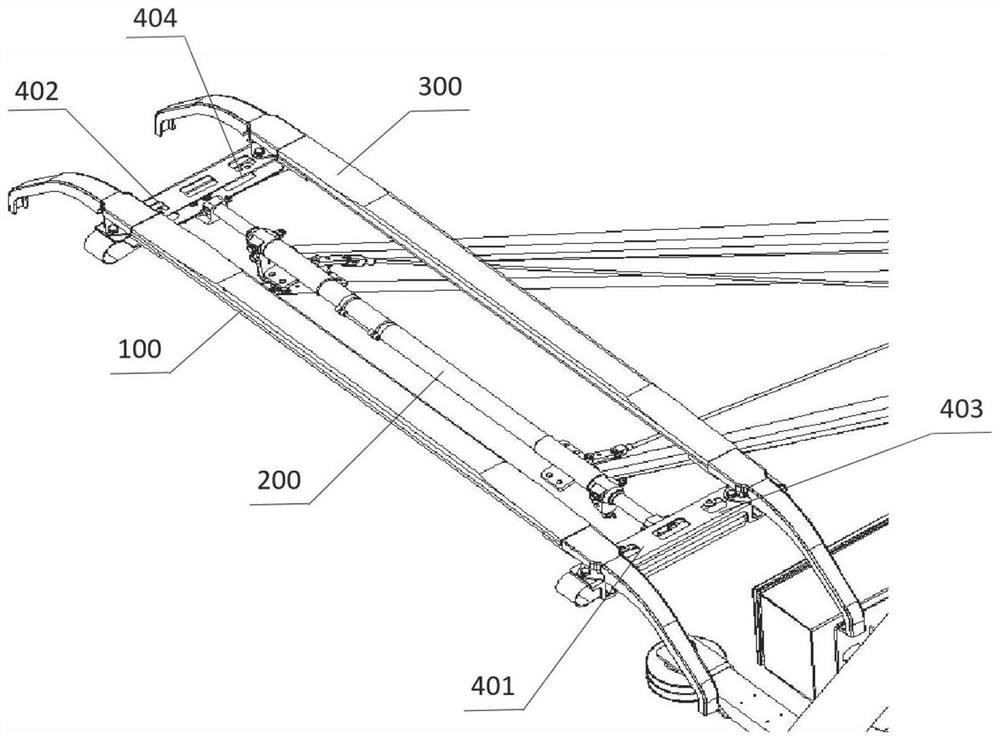

[0051] Step S1, obtain the target image including the first target 501 arranged on the side of the first carbon skateboard 100 and the second target 502 arranged on the side of the upper frame top tube 200 taken by the vertical line array camera arranged on the roof of the train; The vertical plane where the first target 501 and the second target 502 are close to the longitudinal spring 401 on the side of the bow head; there is no strict requirement for the setting positions of the first target 501 and the second target 502, only restricting them to be on the same vertical plane , so that the line-scan camera can capture the light strip images corresponding to the first target 501 and the second target 502 at the same time, through a qualified and accurate calibration process, the connection position between the two ends of the slide plat...

Embodiment 2

[0072] Embodiment 2 provides a non-contact pantograph-catenary contact force calculation device, such as Figure 7 shown, including:

[0073] The target image acquisition module is used to acquire the target image that includes the first target arranged on the side of the first carbon slide plate and the second target arranged on the side of the top pipe of the upper frame taken by the vertical line array camera arranged on the roof of the train; Both the first target and the second target are arranged on a vertical plane near the longitudinal spring on one side of the bow head;

[0074] a light bar pixel extraction module, configured to extract a first light bar pixel corresponding to the first target and a second light bar pixel corresponding to the second target from the target image;

[0075] A first elastic force calculation module, configured to calculate the first elastic force at the first position according to the distance difference between the first light bar pixel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com