Linear motor

A technology of linear motors and coils, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of low processing efficiency, low coil utilization rate, complex process, etc., and achieve the effect of improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

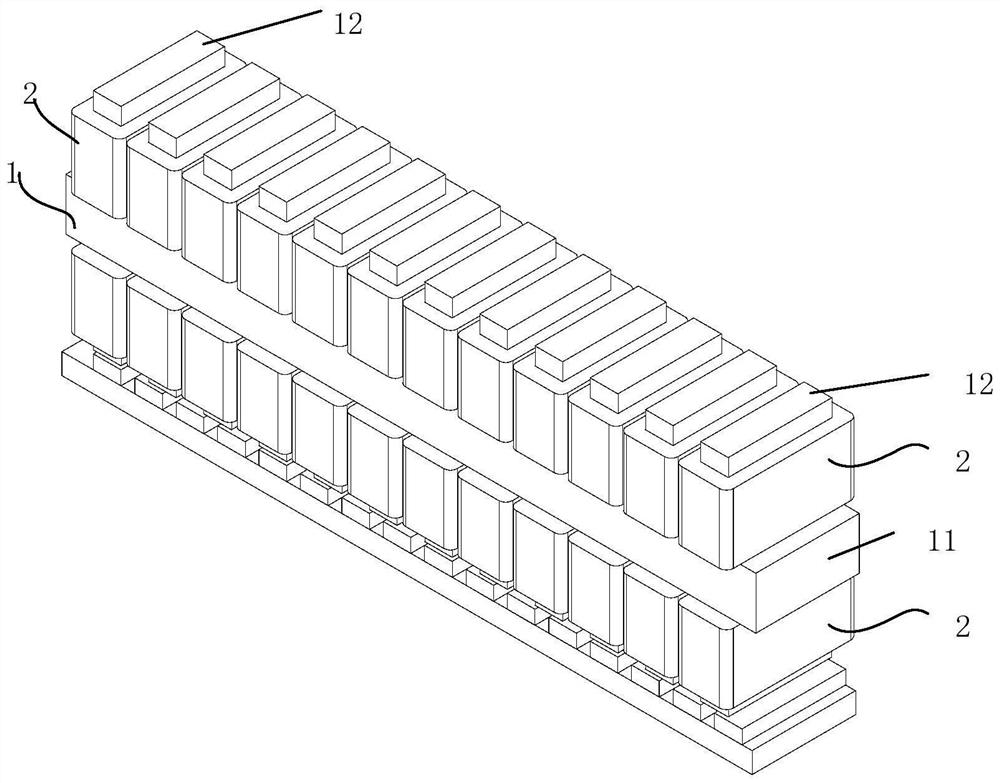

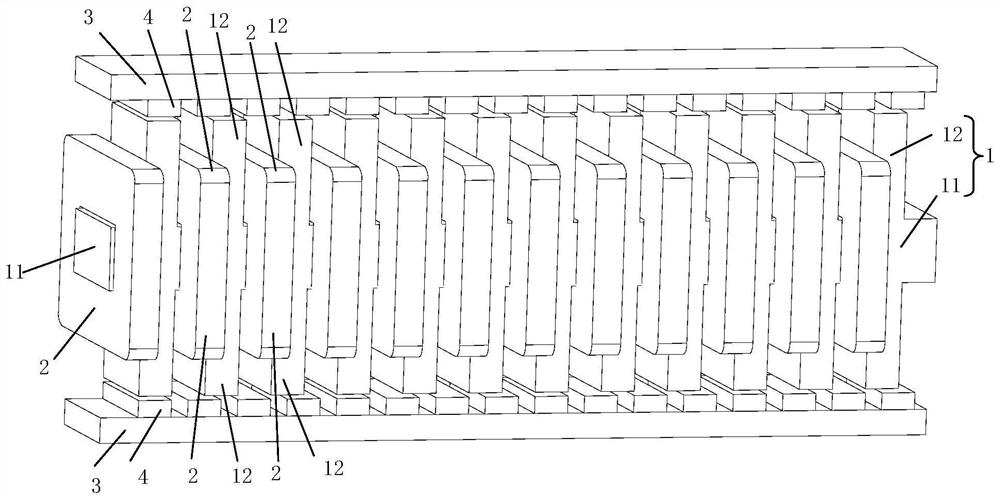

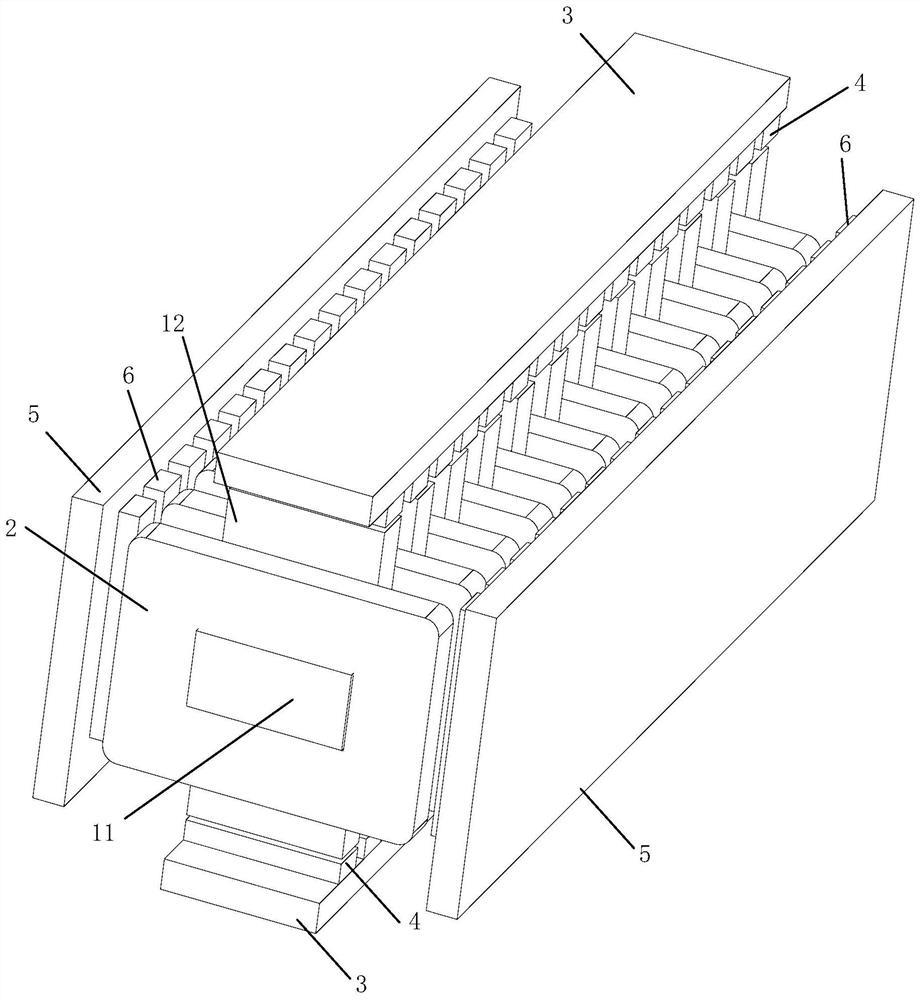

[0059] Optionally, in the first embodiment, one outer side surface of the iron core body 11 provided with the core teeth 12 is provided with the first magnetic conducting plate 3 , and the number of the first magnetic conducting plate 3 is one.

[0060] Optionally, in the first embodiment, the two outer sides of the core body 11 provided with the core teeth 12 are respectively provided with the first magnetic conductive plates 3, and the number of the first magnetic conductive plates 3 is two. indivual.

[0061] Specifically, in this embodiment, the iron core body 11 is a strip-shaped structure arranged along the movement direction of the linear motor. Among all the outer surfaces of the iron core body 11, the four surfaces along the length direction of the strip-shaped structure are called On the outer side, the two ends of the strip structure are called ends. The core teeth 12 are a plurality of protrusions protruding from the core body 11. The core teeth 12 are arranged in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com