Wheat cleaning and drying integrated equipment

A wheat and equipment technology, applied in drying, dryer, drying gas layout and other directions, can solve the problems of high labor intensity of operators, inability to achieve full automation, discontinuous cleaning process, etc., and achieve high cleaning and drying efficiency. Excellent effect and high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

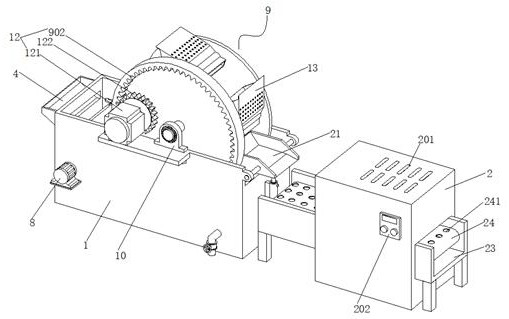

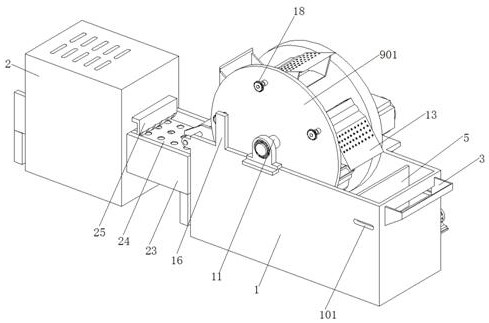

[0041] Embodiment 1 introduces a kind of wheat cleaning and drying integrated equipment, refer to the attached figure 1 And attached figure 2 , its main structure includes a cleaning tank 1 and a dryer 2, and the dryer 2 is set on the right side of the cleaning tank 1, the dryer 2 is a hot air dryer, and on the top of the hot air dryer 2 An exhaust port 201 is arranged on the surface, and a control panel 202 is arranged on the front side of the dryer.

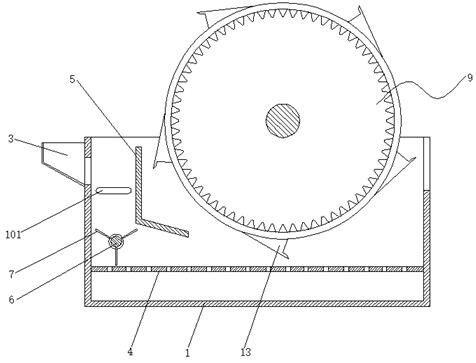

[0042] Reference attached image 3 And attached Figure 4 , a feed hopper 3 is arranged on the left side of the cleaning pool 1, and the wheat raw material can be evenly dropped into the feed hopper 3 by the auger conveyor. A filter plate 4 is arranged at the inner lower end of the cleaning tank 1, and a large number of filter holes are provided on the filter plate 4. The setting of the filter plate 4 is divided into upper and lower areas in the cleaning tank 1. A folded plate 5 is fixedly arranged at the inner left end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com