A fully automatic thread locking device for superimposed workpieces

An automatic locking screw machine and fully automatic technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of low work efficiency, easy fatigue, and high labor intensity of operation, so as to reduce labor intensity and ensure stability Sexuality, the effect of improving processing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

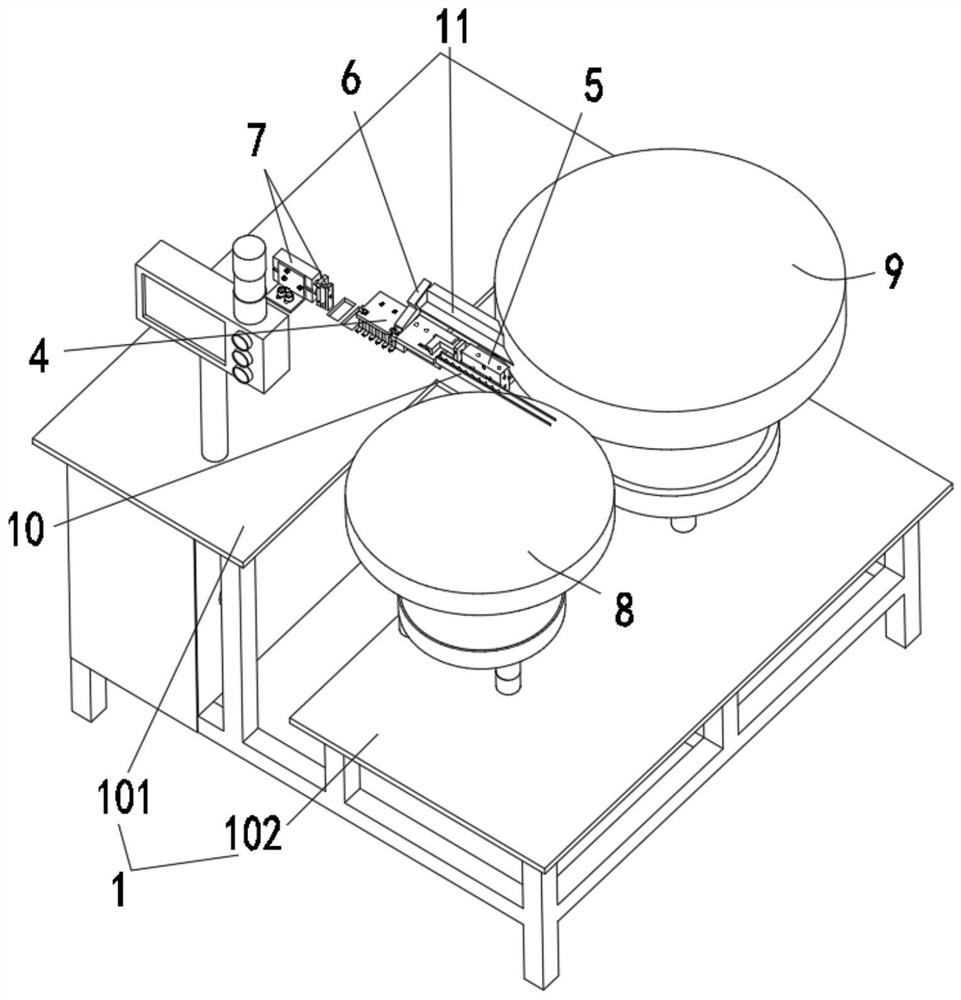

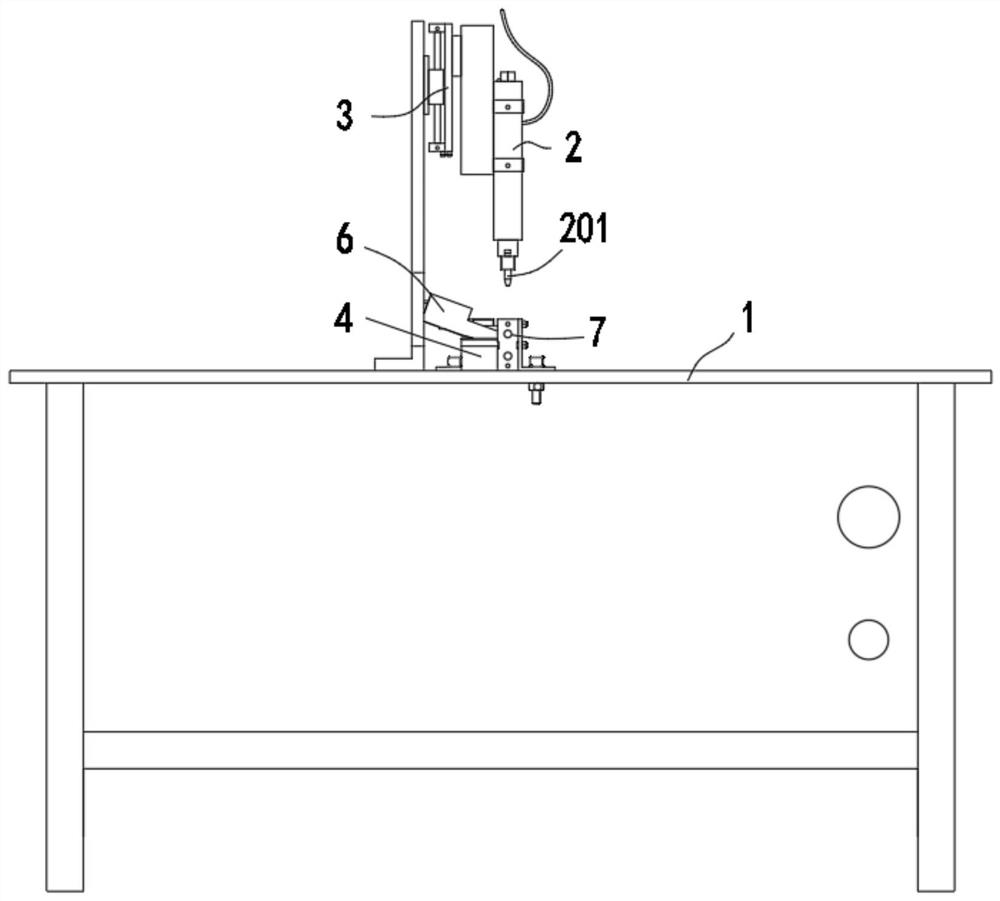

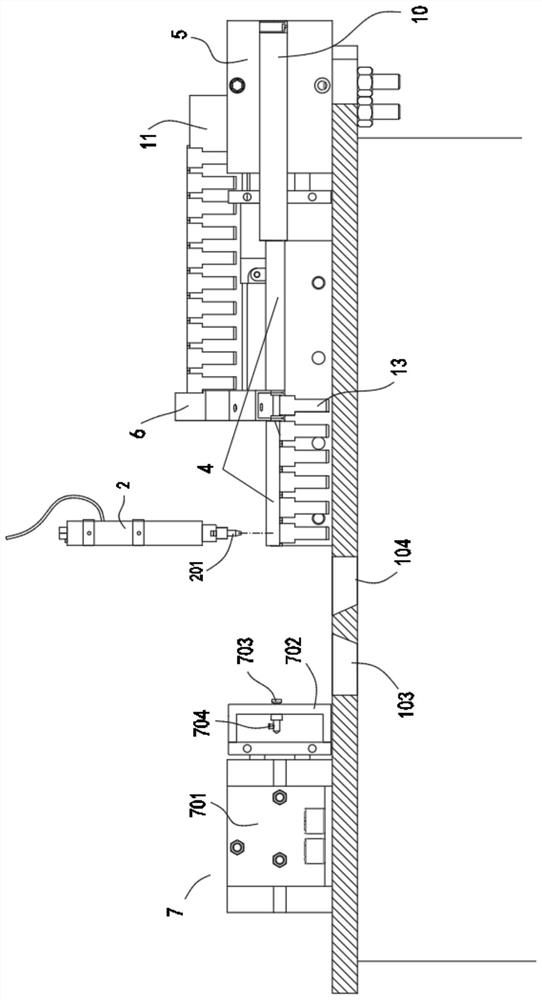

[0038] A kind of fully automatic thread locking equipment for superimposed workpieces in this embodiment, refer to Figure 1-3 , including a support platform 1, the upper side of the support platform 1 is a high platform 101 and a low platform 102 distributed in steps, and the lower side is an elevated support frame, which mainly plays the role of supporting and fixing each structure as a whole.

[0039] And an automatic locking screw machine 2, the exterior of the automatic locking screw machine 2 is connected with a downward pressure cylinder 3, and the clip nozzle 201 of the automatic locking screw machine 2 is vertically downward toward the support platform 1; the automatic locking screw machine 2 is mainly used for stacking The combined locking piece 12+base piece 13 is used for locking screws.

[0040]It also includes a material guide platform 4, which is provided with a continuous stepped groove 401, and a feed groove vertically distributed with the stepped groove 401. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com