Silicon ingot barreling equipment

A silicon ingot and barrel grinding technology, applied in grinding/polishing equipment, metal processing equipment, grinding machines, etc., can solve the problems of complex operation, high cost, and complex equipment structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to facilitate the understanding of the present invention, the present invention will be described more fully below with reference to the associated drawings. A preferred embodiment of the invention is shown in the drawings. However, the present invention can be embodied in many different forms and is not limited to the embodiments described herein. Rather, these embodiments are provided so that the disclosure of the present invention will be thorough and complete.

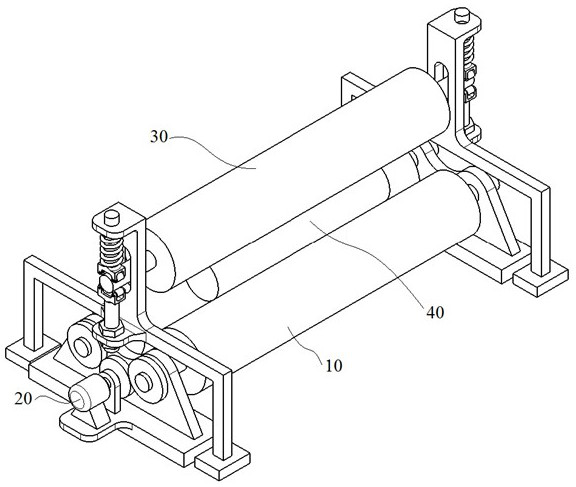

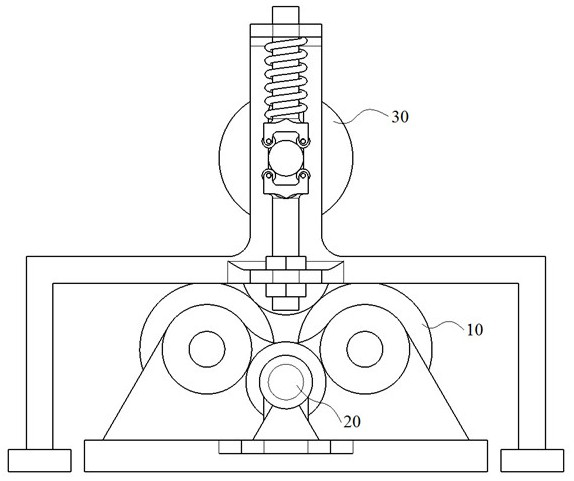

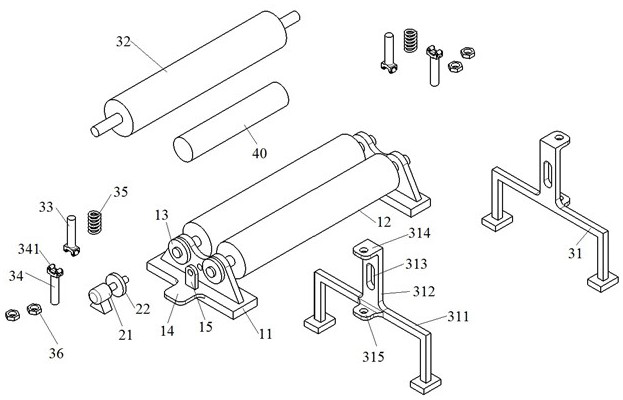

[0018] see Figure 1-Figure 3 The silicon ingot tumbling equipment shown includes a grinding part 10, a driving part 20, a pressing part 30 and a silicon ingot 40, the driving part 20 is installed on the side of the grinding part 10, and the pressing part 30 is located above the grinding part 10 , The regulation 40 is installed between the grinding part 10 and the driving part 20 .

[0019] Grinding section 10 comprises base 11, grinding stick 12, driven wheel 13, platform 14 and side plate 15, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com