Simple polishing machine for mobile phone shell

A mobile phone shell and polishing machine technology, which is applied to surface polishing machine tools, grinding/polishing equipment, grinding racks, etc., can solve problems such as fast speed, large quantity, missed throwing and scratches, etc. The effect of a large number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

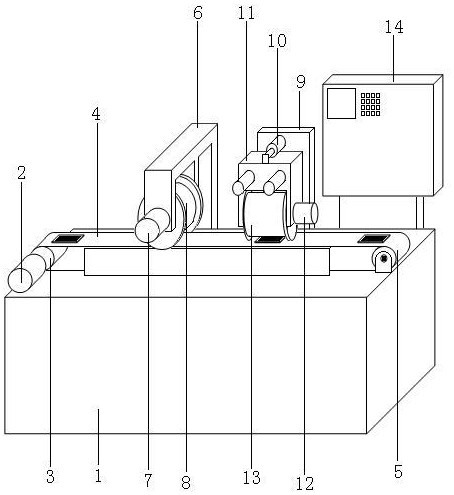

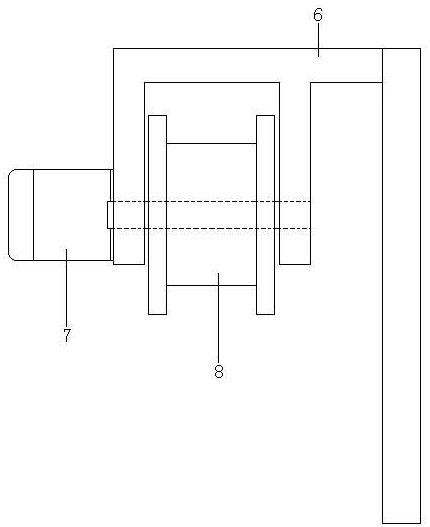

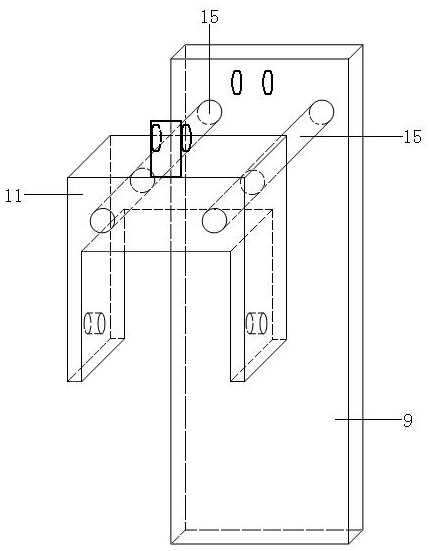

[0022] A simple polishing machine for a mobile phone shell, characterized in that it includes a frame, a servo motor (AC220V / 200W), an active synchronous wheel, a synchronous conveyor belt, a supporting synchronous wheel, a transverse polishing bracket, a transverse polishing motor (AC220V / 150W), a transverse polishing wheel, longitudinal polishing bracket, two-way cylinder (1kpa), sliding bracket, longitudinal polishing motor (AC220V / 150W), longitudinal polishing wheel, control box, support rod, electric control valve (DC12V / 10A, 1kpa), power supply (AC220V / 10A, DC12V20A), display (DC12V / 2A), multi-channel controller (AC220V / 6A, DC12V / 15A), power cord (3x2.5mm²), air supply pipe (4kpa);

[0023] The frame is in the shape of a cuboid, and a cylindrical active synchronous wheel is longitudinally arranged in the center of the upper left through two semicircular bearing seats, and a cylindrical servo motor is longitudinally arranged on the frame in front of the active synchronous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com