A kind of installation method of saturation diving pressure chamber

An installation method and pressure chamber technology, applied to ships and other directions, to achieve the effects of simplifying the installation method, shortening the installation period, and reducing the positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

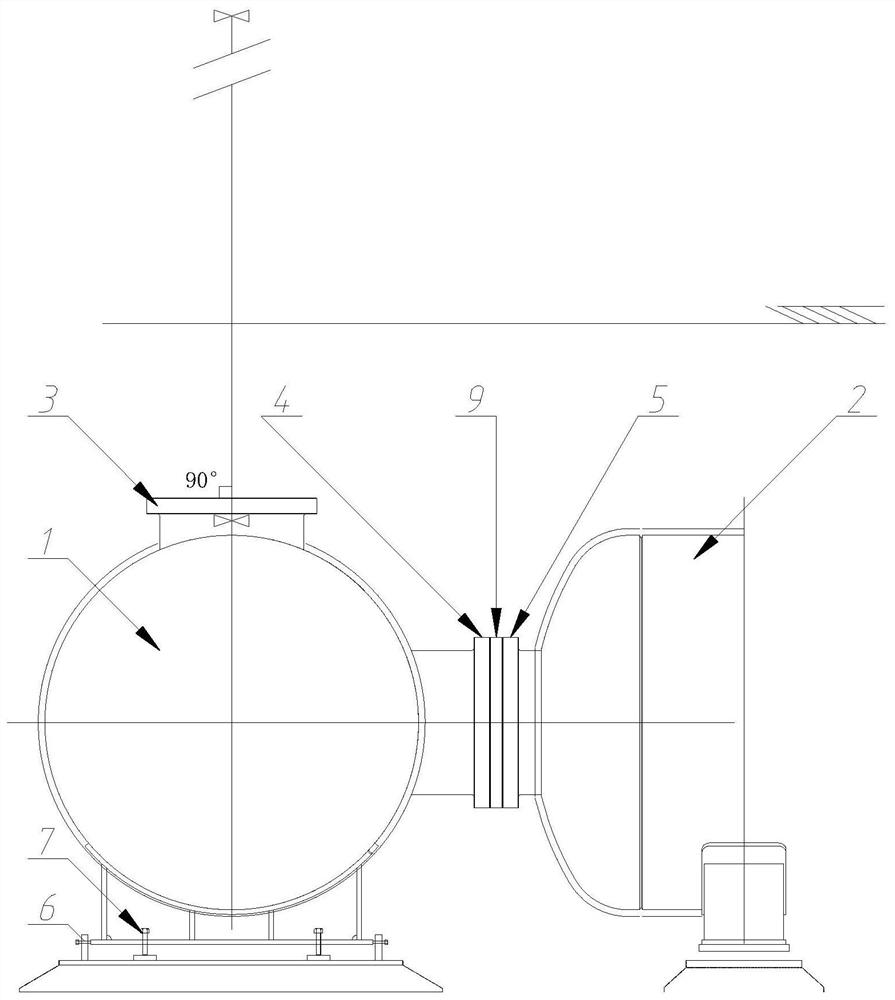

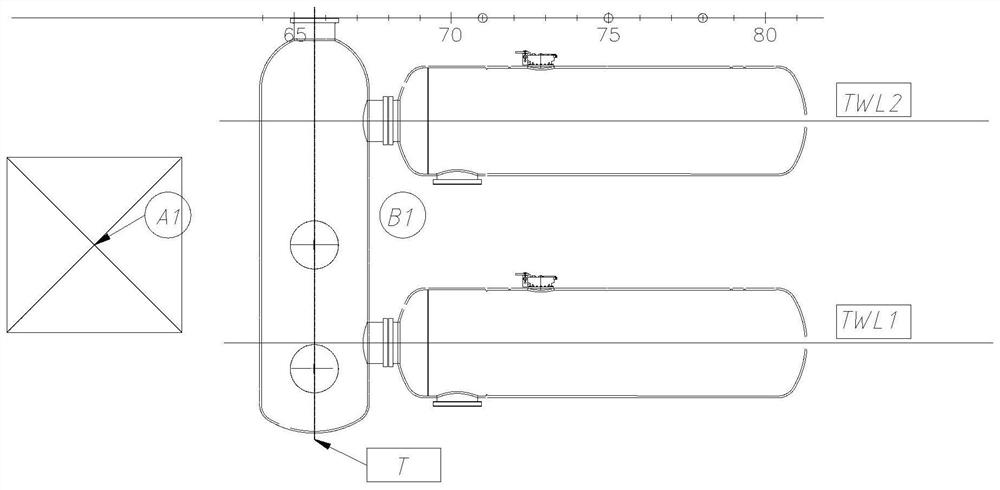

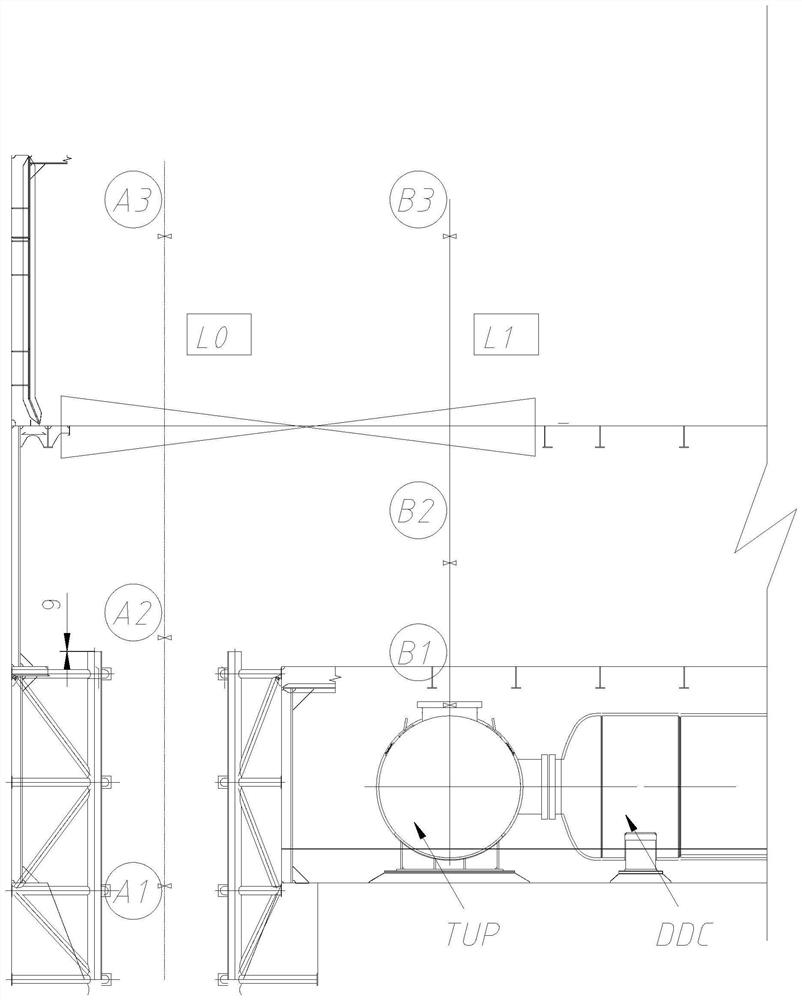

[0033] Such as Figure 1 to Figure 3 Shown is a specific implementation of a saturated diving pressure chamber installation method provided by the present invention, the installation method includes the following steps:

[0034] S1 Determine the corresponding positioning reference line for installing the diving transfer cabin 1 and the diving living cabin 2 on the deck, and set the TUP adjustment tool and the DDC adjustment tool on the deck at the position of the positioning reference line;

[0035] S2, place the diving transfer cabin 1 and the diving living cabin 2 on the TUP adjustment tool and the DDC adjustment tool respectively, and complete the preliminary positioning;

[0036] S3, setting the precise positioning line of the diving transfer cabin 1, and completing the final positioning of the diving transfer cabin 1 through the precise positioning line;

[0037]S4, fine-tune the diving living cabin 2 through DDC adjustment tooling, so that the distance, deflection angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com