Full-automatic filling and lifting mechanism

A fully automatic, transmission mechanism technology, applied in the direction of packaging, etc., can solve the problems affecting the full automation control of the filling process, liquid food overflow, and the box cannot be sucked down, so as to facilitate automatic control, stable filling process and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

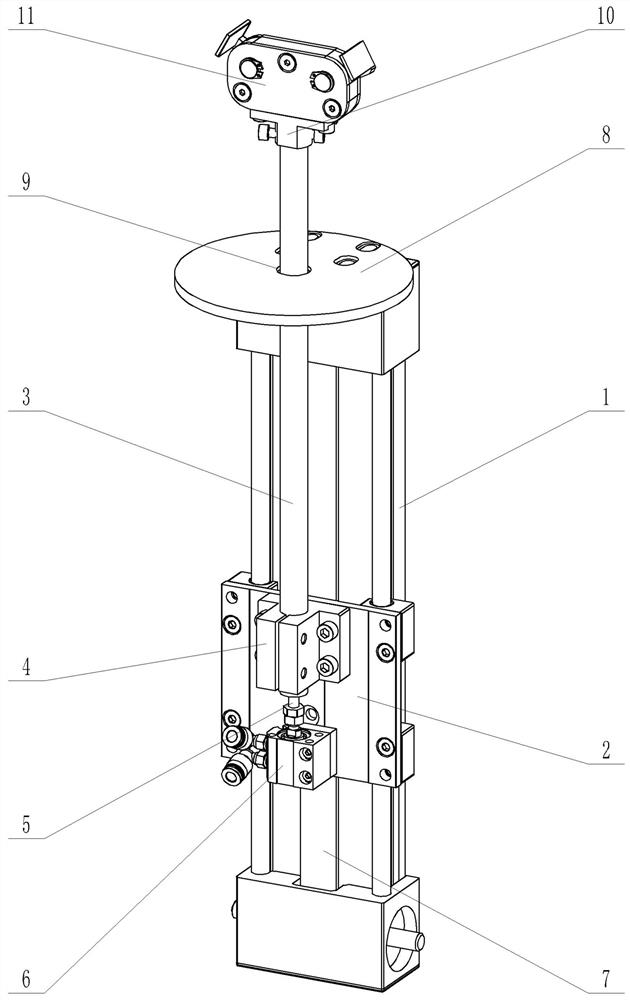

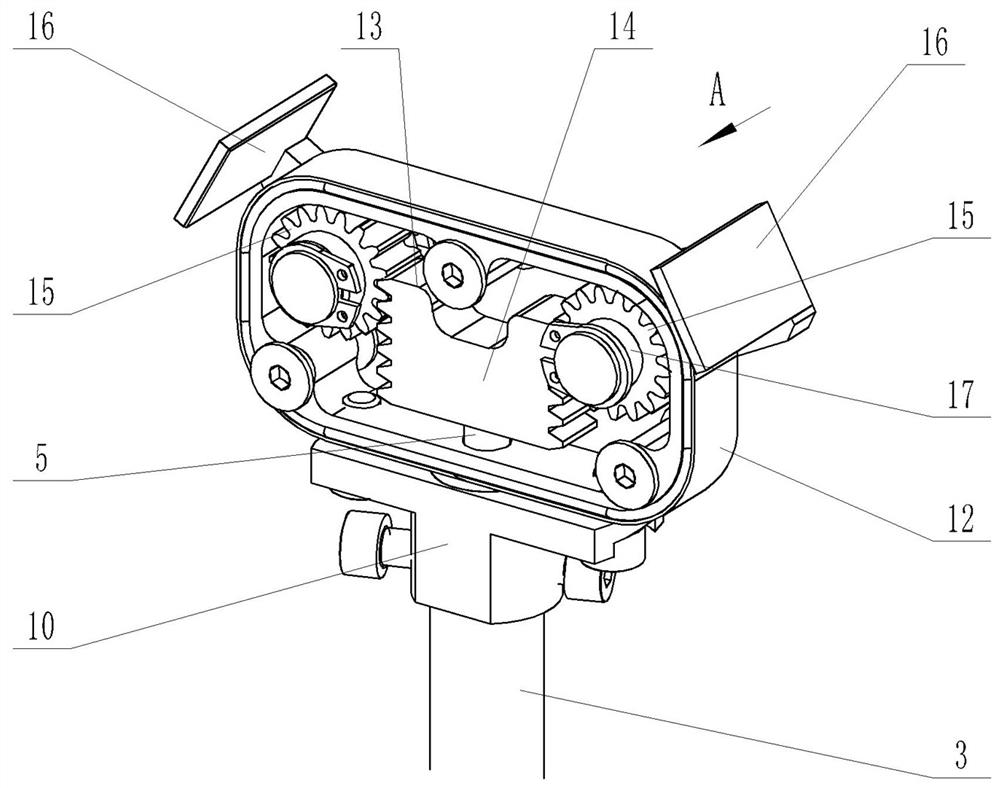

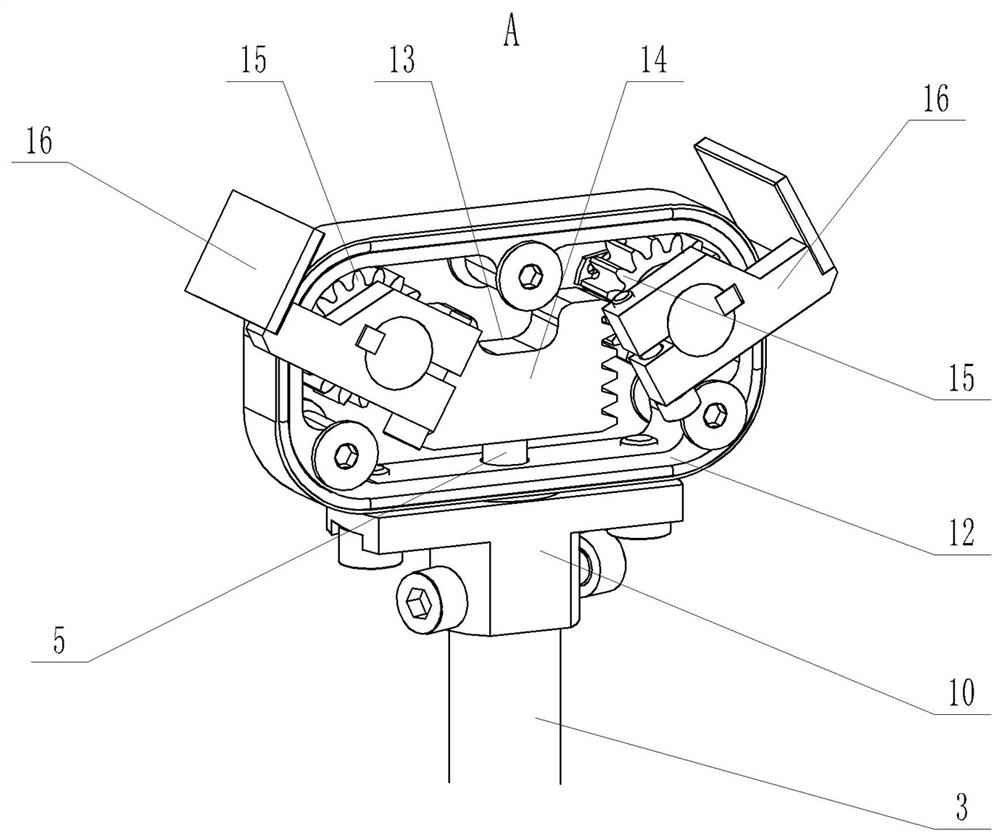

[0025] according to Figure 1-10 The specific structure of the present invention will be described in detail. The fully automatic filling lifting mechanism includes a vertical track base 1, on which a lifting slide 2 that can slide up and down is arranged, and the driving end of the lifting slide 2 is connected with the slide drive mechanism 7; And in combination with specific use requirements, the transmission mode of the sliding seat driving mechanism 7 can adopt belt transmission, linear motor transmission, pneumatic transmission, lead screw transmission, rack and pinion transmission or electromagnetic transmission, etc. The lifting slide 2 is provided with a vertically upwardly arranged hollow structure jaw lifting rod 3, the lower end of the jaw lifting rod 3 is connected with the lifting slide 2 through the lifting rod connecting seat 4, and the jaws are lifted The upper end of the rod 3 is provided with a filling box clamping claw 11 .

[0026] In the through cavity i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com