Auxiliary feeding device for glass processing and feeding method

A glass and clamping seat technology, which is applied in the field of auxiliary feeding devices for glass processing, can solve the problems of potential safety hazards and inconvenient operation, and achieve the effects of saving physical expenditure, preventing glass from falling, and simple and labor-saving operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

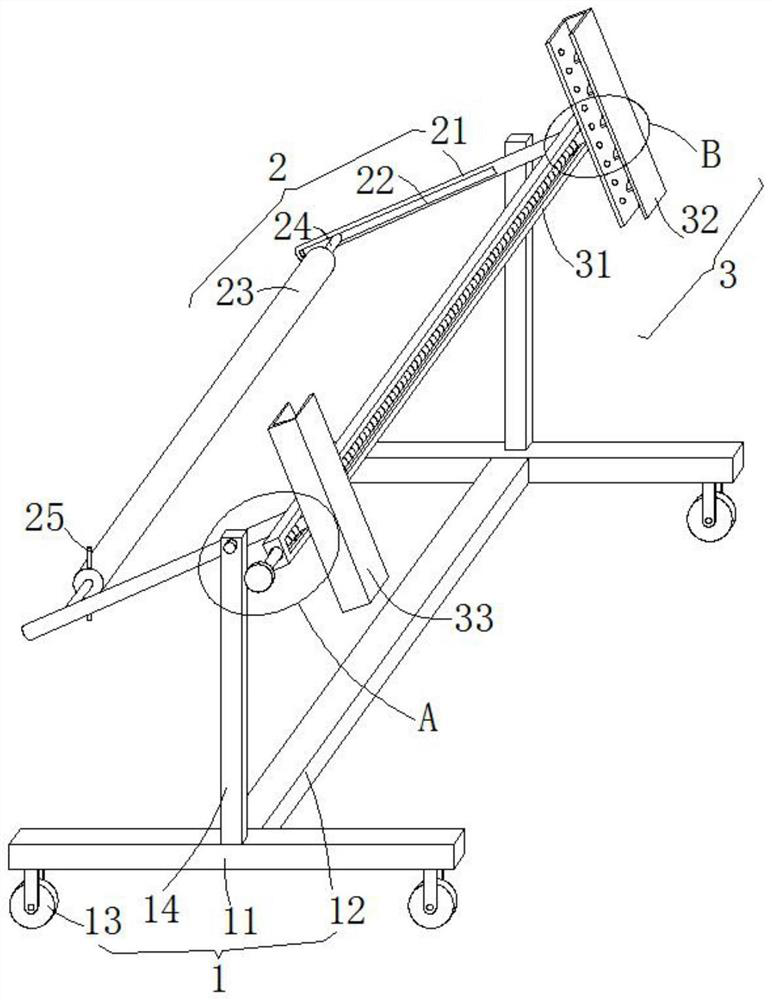

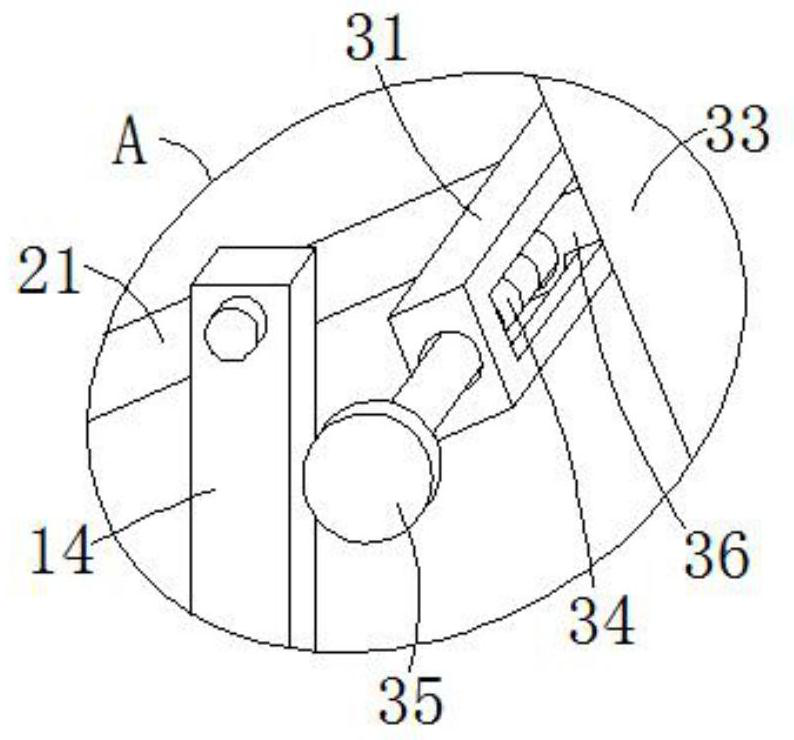

[0027] see Figure 1-3 , the present embodiment provides an auxiliary feeding device and a feeding method for glass processing, including a supporting mechanism 1, an auxiliary rotating mechanism 2 and a clamping mechanism 3, and the supporting mechanism 1 includes two supporting bottom beams 11, two supporting The column 14 and the connecting rod 12 support the overall structure through the support mechanism 1. The auxiliary rotation mechanism 2 includes two hinged rods 21 and a counterweight roller 23. The auxiliary rotation mechanism 2 is used to assist the flipping of the clamping mechanism 3 to facilitate the clamping After the angle of the glass is adjusted, the loading operation is convenient. The clamping mechanism 3 includes a rectangular beam 31, a first clamping seat 33 and a second clamping seat 32, and the clamping mechanism 3 assists in clamping the glass for loading operation.

[0028] The two supporting bottom beams 11 are distributed in front and back, and the...

Embodiment 2

[0036] see image 3 , further improvements have been made on the basis of Example 1:

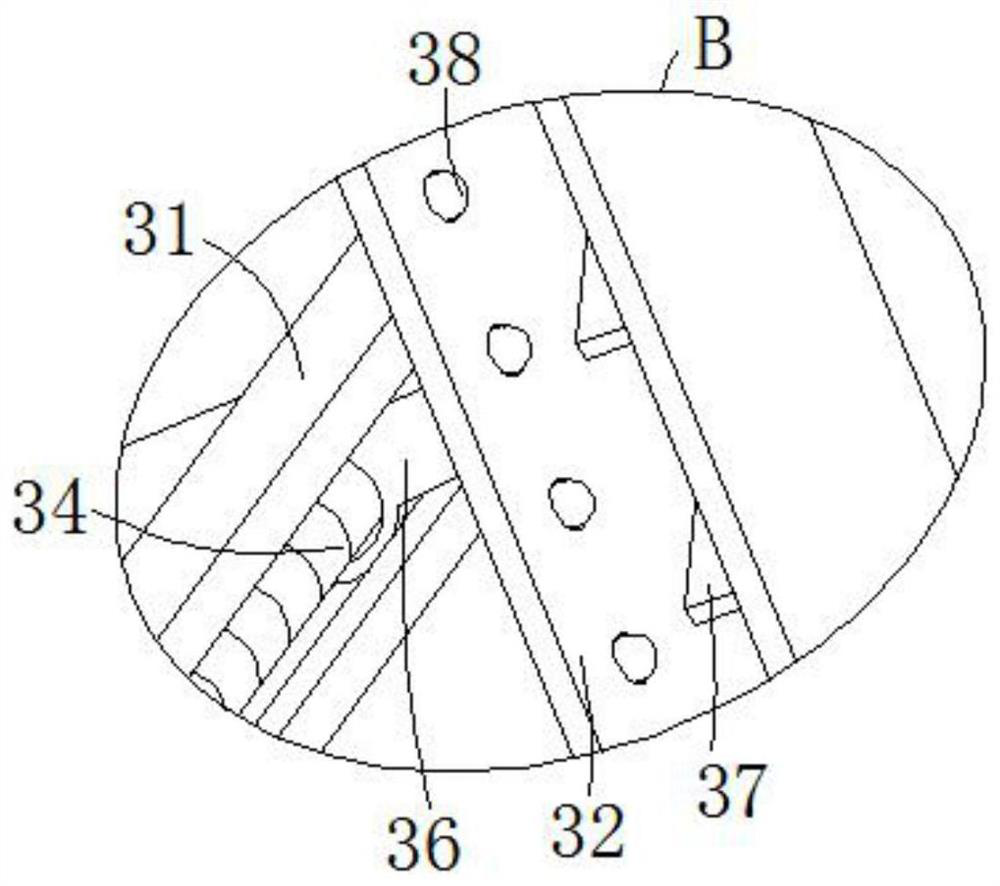

[0037] The inner cavity of the first clamping seat 33 and the second clamping seat 32 is provided with a PVC plastic top sheet 37 inclined 45° to the side of the opening away from the side wall of the opening, and each PVC plastic top sheet 37 The outer walls are all wrapped with rubber sleeves. By setting several PVC plastic top sheets 37 wrapped with rubber sleeves on the first clamping seat 33 and the second clamping seat 32 inner cavity side walls, when the first clamping seat 33 and the second clamping seat 33 When the clamping seat 32 clamps the glass, the PVC plastic top sheet 37 is squeezed and deformed, which can increase the clamping friction of the glass while clamping the glass, preventing the glass from falling during the clamping process.

[0038] The inner cavity of the first clamping seat 33 and the second clamping seat 32 are close to the side wall of the rectangular beam 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com