Tipping paper deviation rectifying mechanism

A technology of tipping paper and rectifying rollers, which is applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve problems such as affecting machine efficiency, affecting product quality, unqualified cigarettes, etc., to solve the problem of reciprocating deviation , Reduce the risk of paper breakage, easy to manufacture and maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

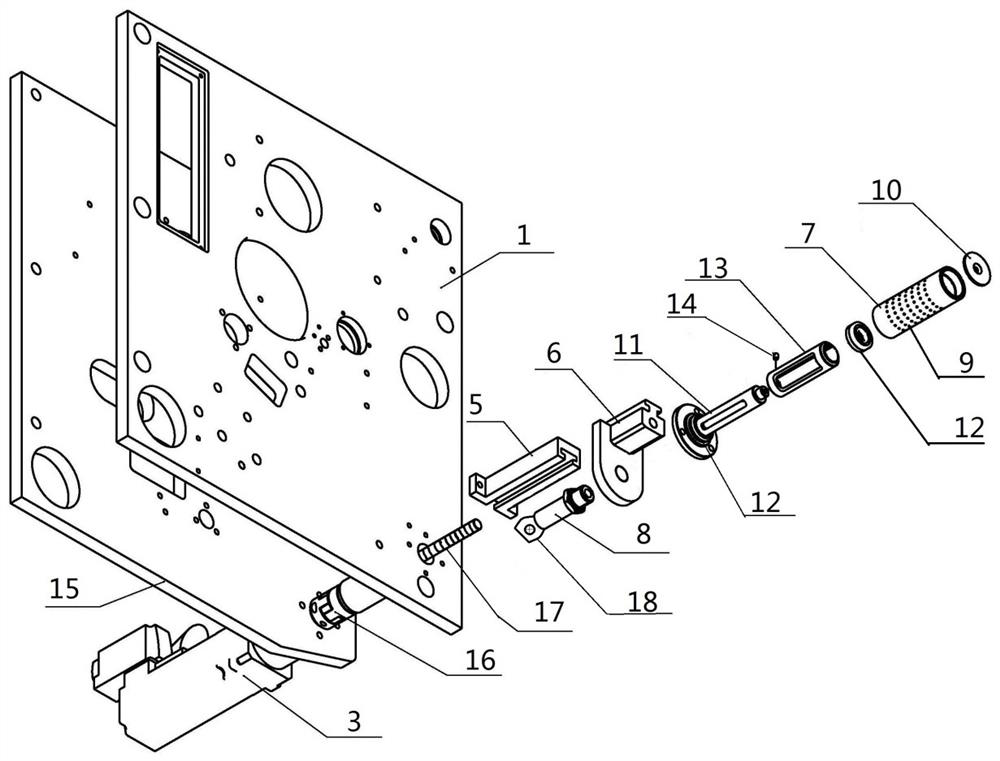

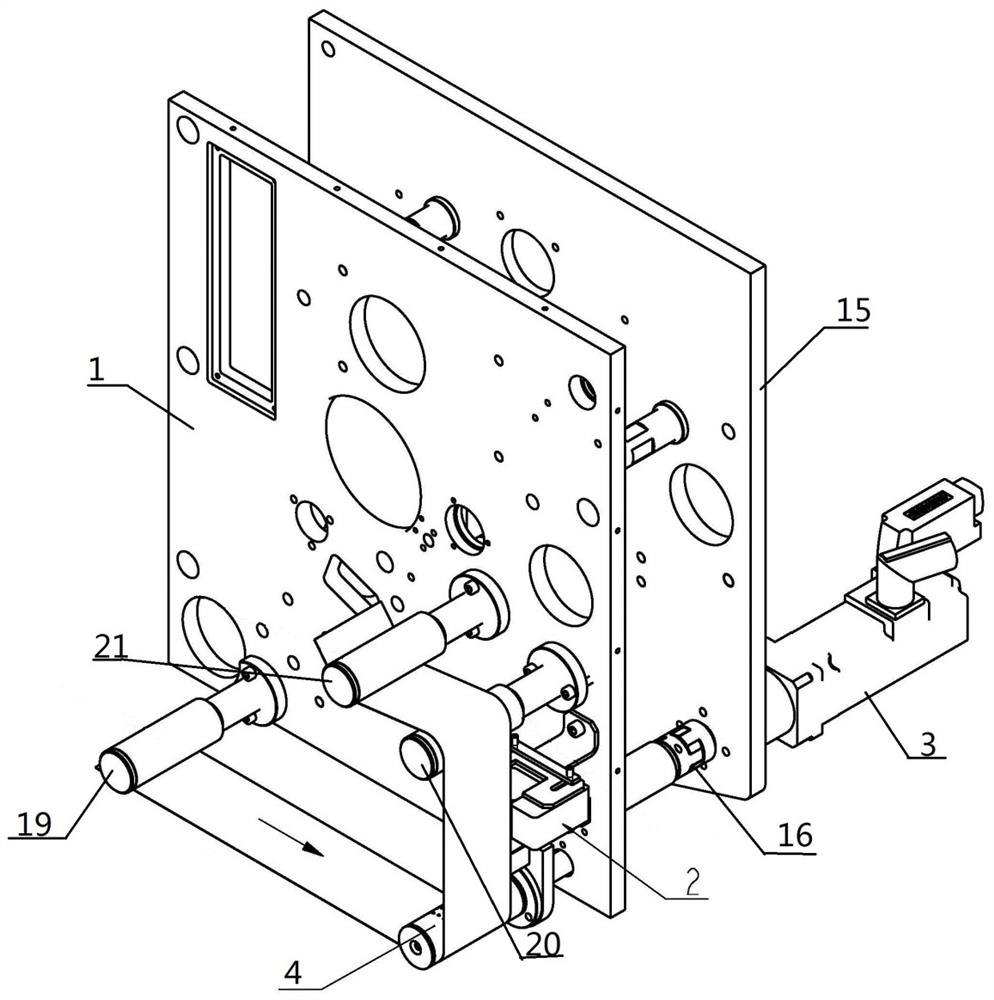

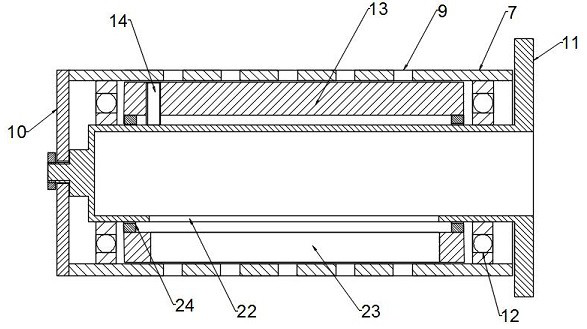

[0031] Such as figure 1 , figure 2 and image 3 As shown, a tipping paper deviation correction mechanism includes a wallboard 1, a paper sensor 2, a servo motor 3, a linear guide rail 5, a deviation correction roller assembly 4 and a negative pressure air duct 8; the paper sensor 2 is fixedly connected to the front of the wallboard 1; The linear guide rail 5 is fixedly connected under the paper sensor 2, the linear guide rail 5 is slidably connected with a slider 6, and a threaded through hole is opened on the slider 6; the servo motor 3 is connected to the paper sensor 2 signal, and the servo motor 3 is fixedly connected to the wallboard 1. On the back side, the end of the servo motor 3 close to the wallboard 1 is provided with an output shaft, the output shaft penetrates through the wallboard 1 and is connected to the threaded through hole on the slider 6, and the end of the slider 6 away from the output shaft is rotatably connected with a deviation correction roller assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com