Slime water mixed dosing and filter press linkage system and method for coal dressing

A linkage system, slime water technology, applied in chemical instruments and methods, water/sludge/sewage treatment, filtration treatment, etc., can solve the problems of unquantifiable operation process, complicated device structure, troublesome control, etc., and achieve shortening of dosing Time, reduce labor intensity, reduce the effect of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]The present invention will be further described in detail below with reference to the drawings and embodiments. The following embodiments are for explaining the present invention and the present invention is not limited to the following embodiments.

[0023]Examples.

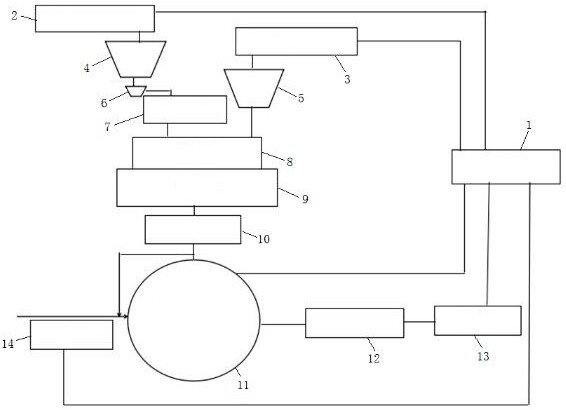

[0024]Seefigure 1.

[0025]This embodiment discloses a coal preparation slime water mixing dosing and filter press linkage system, which includes a controller 1, No. 1 automatic dosing belt 2, No. 2 automatic dosing belt 3, No. 1 funnel 4, No. 2 The funnel 5, the gas ring vacuum pump 6, the mixing device 7, the mixing barrel 8, the medicine storage tank 9, the drug delivery device 10, the concentration tank 11, the filter press feed barrel 12, the filter press 13 and the slime water main pipe 14.

[0026]In this embodiment, the first automatic dosing belt 2 and the second automatic dosing belt 3 are both communicatively connected with the controller 1. The first automatic dosing belt 2 is used to add an anionic agent to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com