Soap stamping device

A stamping and soaping technology, applied in embossing/polishing soap, etc., can solve the problems of different stamping depths on the soap surface, low operating efficiency, and easy fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

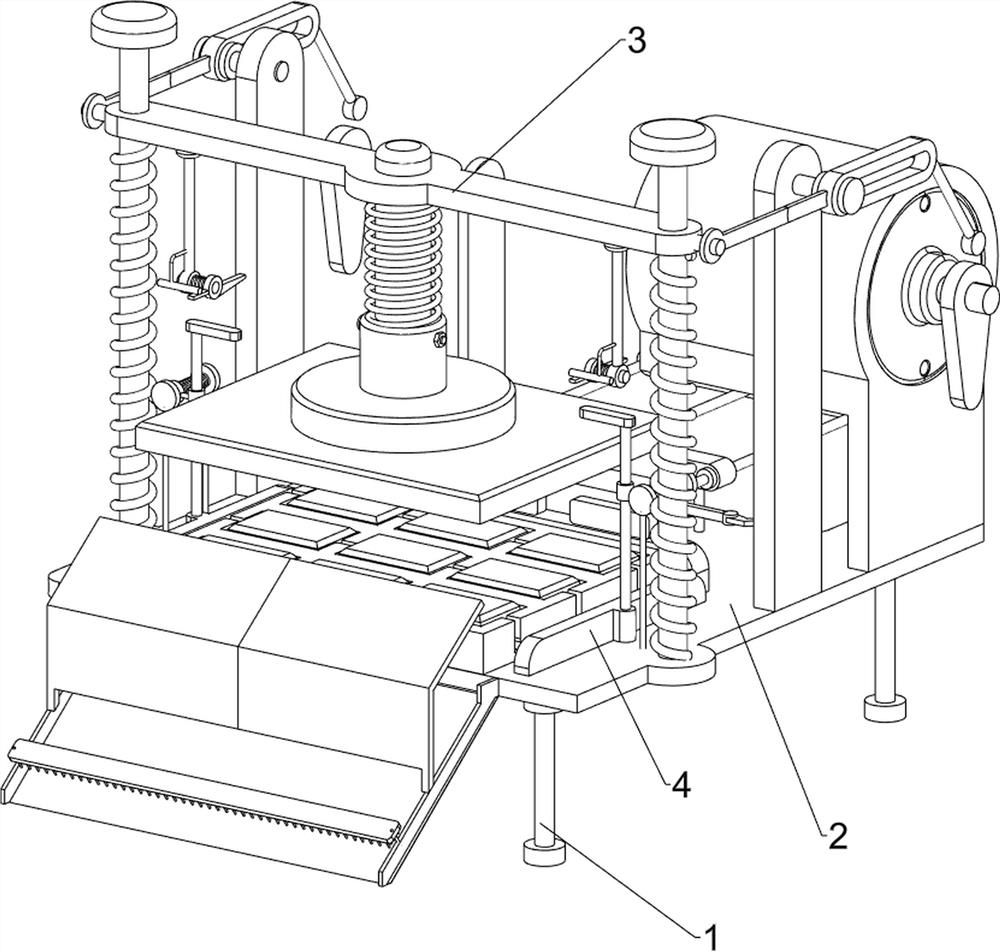

[0022] like figure 1 , figure 2 and image 3 As shown, a soap stamping device includes a support column 1, a worktable 2, a stamping mechanism 3 and a stripping mechanism 4, the four corners of the bottom of the workbench 2 are provided with support columns 1, and the top of the workbench 2 is provided with There is a stamping mechanism 3, and a stripping mechanism 4 is arranged on the top of the workbench 2, and the stripping mechanism 4 is located below the stamping mechanism 3.

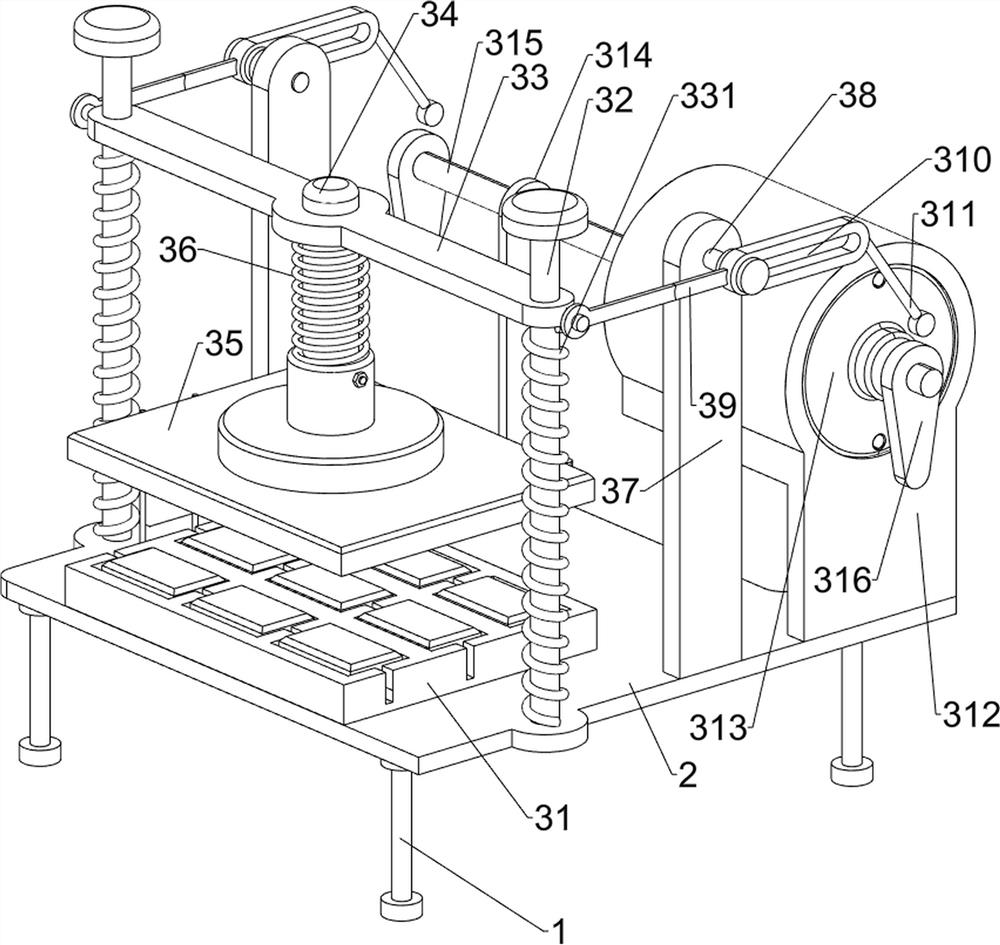

[0023] Stamping mechanism 3 comprises placement table 31, column 32, first connecting rod 33, first elastic member 331, round rod 34, printing plate 35, second elastic member 36, first bearing seat 37, fixed shaft 38, the first Two connecting rods 39, chute 310, fork 311, fixed seat 312, biaxial motor 313, second bearing seat 314, first rotating shaft 315 and cam 316, the front side of the top of the workbench 2 is provided with a placement platform 31, the placement platform 31 is evenly space...

Embodiment 2

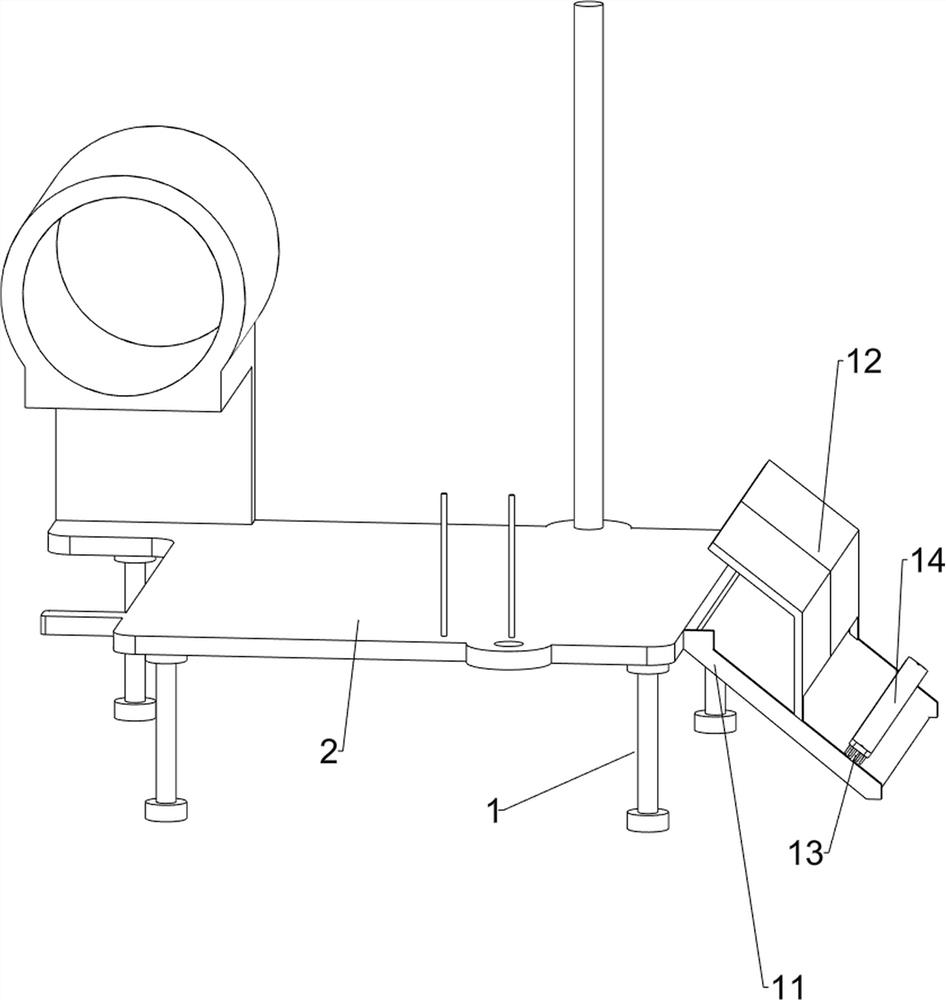

[0027] like Figure 4 and Figure 5 As shown, on the basis of Embodiment 1, a soap imprinting device also includes a second fixed block 5, a slide bar 6, a push plate 7, a connecting plate 8, a driving lever 9 and an elastic pawl 10, and a working table 2. A second fixed block 5 is arranged on the rear side of the top, and sliding rods 6 are evenly spaced inside the second fixed block 5. Push plates 7 are arranged at the front ends of the sliding rods 6, and connecting plates are arranged between the rear ends of the sliding rods 6. 8. The front sides of the slide bars 6 on the left and right sides are symmetrically provided with driving rods 9 , and the outer sides of the two driving rods 9 are provided with elastic pawls 10 , and the elastic pawls 10 cooperate with the second guide rods 45 which are similar.

[0028] The top plate 49 moves upwards and ejects the stamped soap from the three square holes of the placing table 31. The staff closes the biaxial motor 313, holds t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com