Flow adjusting structure

A technology of blades and air inlets, which is applied in the direction of mufflers, engine components, machines/engines, etc., which can solve the problems of accelerated carrier aging, air intake flanges that cannot adjust the airflow velocity, and large airflow velocity, so as to achieve uniform velocity and facilitate The effect of promoting the use and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

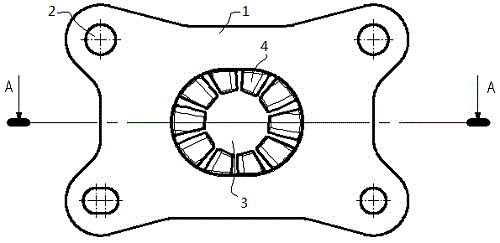

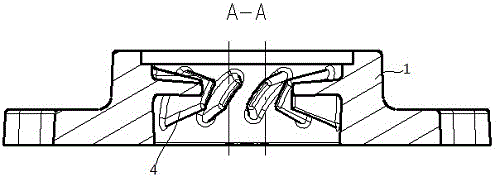

[0024] Combine figure 1 with figure 2 As shown, a rectifying structure of this embodiment includes an air inlet flange formed by one-time casting. The air inlet flange includes a flange body 1 and a blade 4. The flange body 1 is provided with mounting holes 2 around the flange. An air inlet 3 is provided in the middle of the main body 1, and fan-shaped blades 4 are evenly distributed in the inner circumferential direction of the air inlet 3, which can better guide and buffer the airflow. Each blade 4 is tapered in size along the direction extending from the inner side of the air inlet 3 to the center of the air inlet 3 (that is, the length of the corresponding arc segment at the center of each blade 4 close to the air inlet 3 gradually decreases. Small), each blade 4 is distributed obliquely on the inner side of the inlet 3, and the inclination direction is the same. Each blade 4 is distributed clockwise or counterclockwise on the inner circumference of the inlet 3 (that is, t...

Embodiment 2

[0027] The basic structure of a rectifying structure of this embodiment is the same as that of Embodiment 1, and the difference is that the included angle δ in this embodiment is 30°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com