A leak-proof structure for board seams, a prefabricated roof panel and a prefabricated roof panel system

A roof panel and prefabricated technology, applied in the direction of roof, roof decoration, building components, etc., can solve the problem of easy falling off of micro-expanded mortar, and achieve the effect of improving waterproof performance, improving service life and good waterproof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

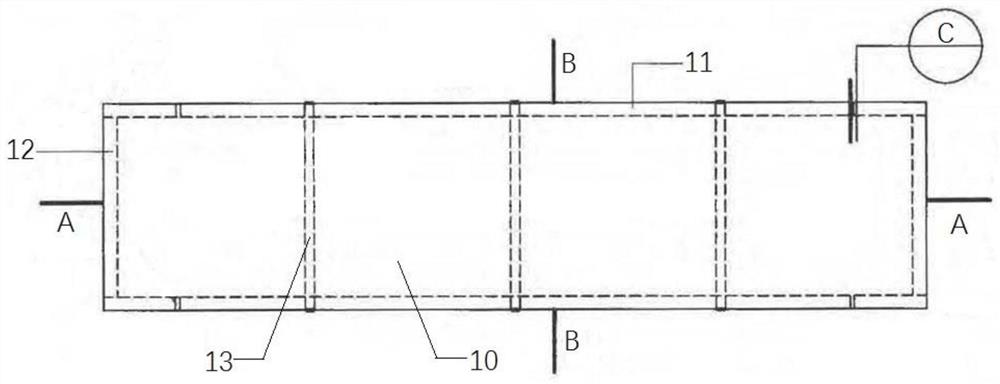

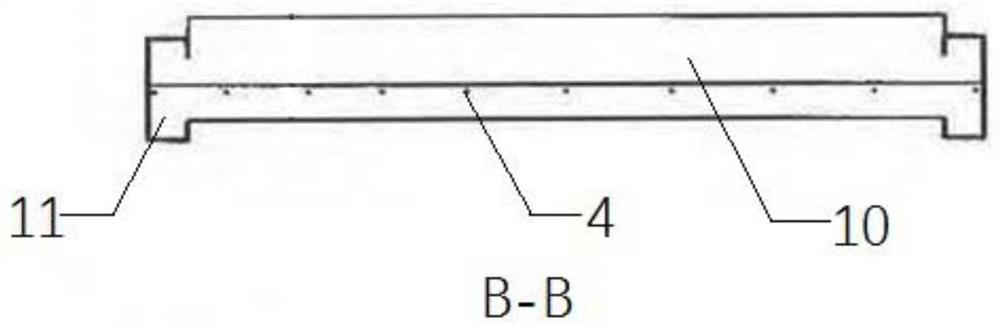

[0047] see Figure 1 to Figure 3 and Figure 5 to Figure 6 , The present embodiment provides a seam leak-proof structure for a prefabricated roof panel, which includes a first leak-proof layer and a second leak-proof layer. The first anti-leakage layer includes two sets of flexible structures 2, and the two sets of flexible structures 2 are respectively arranged on the main ribs 11 of two adjacent roof panels 1, that is to say, the two sets of flexible structures 2 are arranged on two adjacent roofs. At the butt joints of the main ribs 11 of the panels 1 , the second leak-proof layer is filled between the joints of two adjacent roof panels 1 and is located above the flexible structure 2 .

[0048] Specifically, for any set of flexible structures 2, such as Figure 5 to Figure 6As shown, it includes a main body portion 20 and a convex portion 21. The main body portion 20 is L-shaped and includes a pad portion 201 that is padded at the bottom end of the main rib 11 and an exte...

Embodiment 2

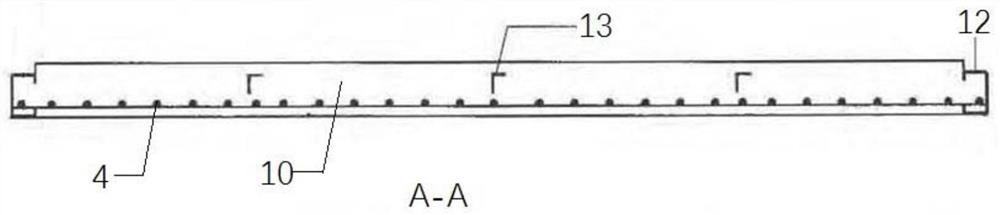

[0052] see Figure 1 to Figure 6 , A prefabricated roof panel 1 provided in this embodiment includes a roof panel body 10 , a main rib 11 , an end rib 12 , a reinforcing rib 13 and the plate seam leak-proof structure in the above-mentioned embodiment 1. The main body 10 of the roof panel is a rectangular roof panel, which is composed of a light steel outer frame around it and a concrete structure layer filled in the light steel outer frame. , there is no detailed description and limitation. Those skilled in the art can choose the composite core according to actual needs. For example, the composite core can include a thickness of 30cm and a density of 500kg / m 3 The core board is 48cm thick and has a density of 300kg / m 3 The core board and the thickness of 20cm, the density of 500kg / m 3 The core board is laminated up and down, such as Figure 4 As shown, the steel bar 4 includes a plurality of steel bars, and the plurality of steel bars 4 are arranged in parallel and perpendi...

Embodiment 3

[0055] see Figure 1 to Figure 6 , A prefabricated roof panel system provided in this embodiment includes a plurality of prefabricated roof panels 1 in Embodiment 2, and is formed by splicing a plurality of prefabricated roof panels 1 in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com